Polymer foam material and its preparation method

A technology for foaming materials and polymers, applied in the field of polymer foaming materials and its preparation, can solve problems such as affecting foaming, seriousness, and leakage of flame retardants, to reduce the difference in viscoelasticity, and the preparation method is simple and good scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

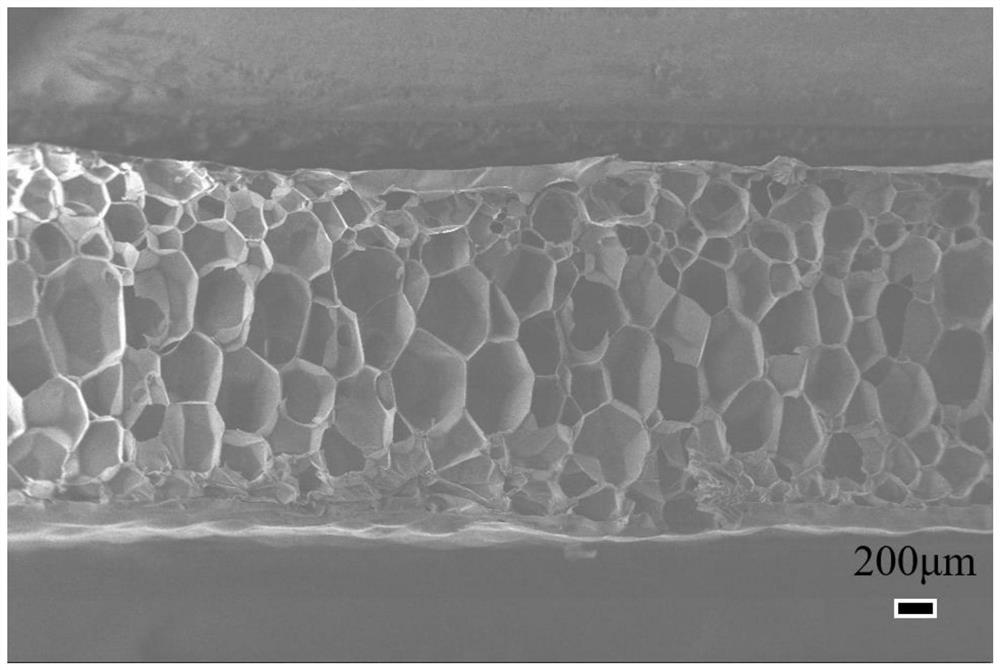

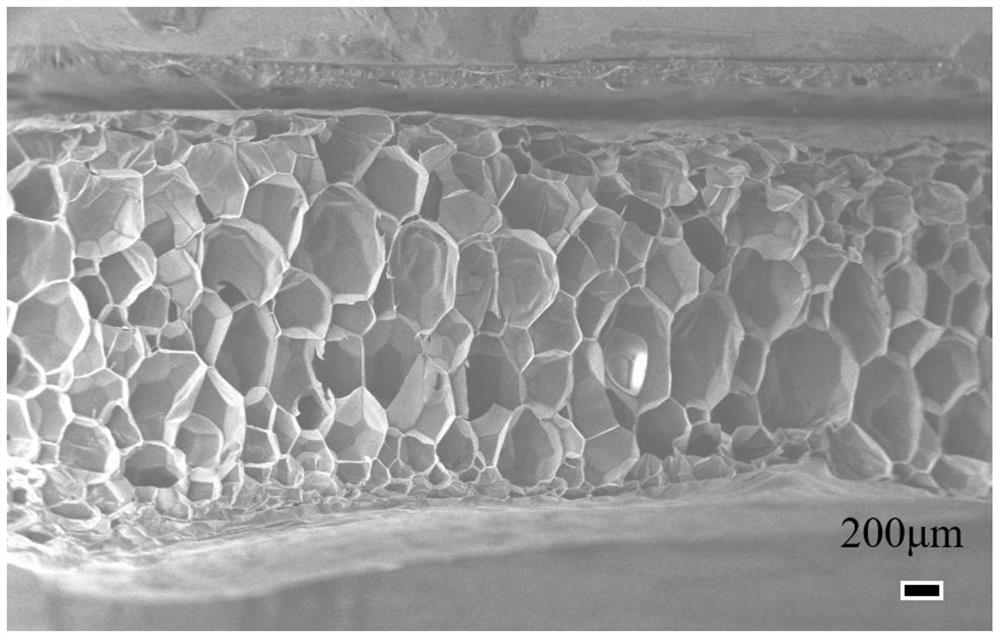

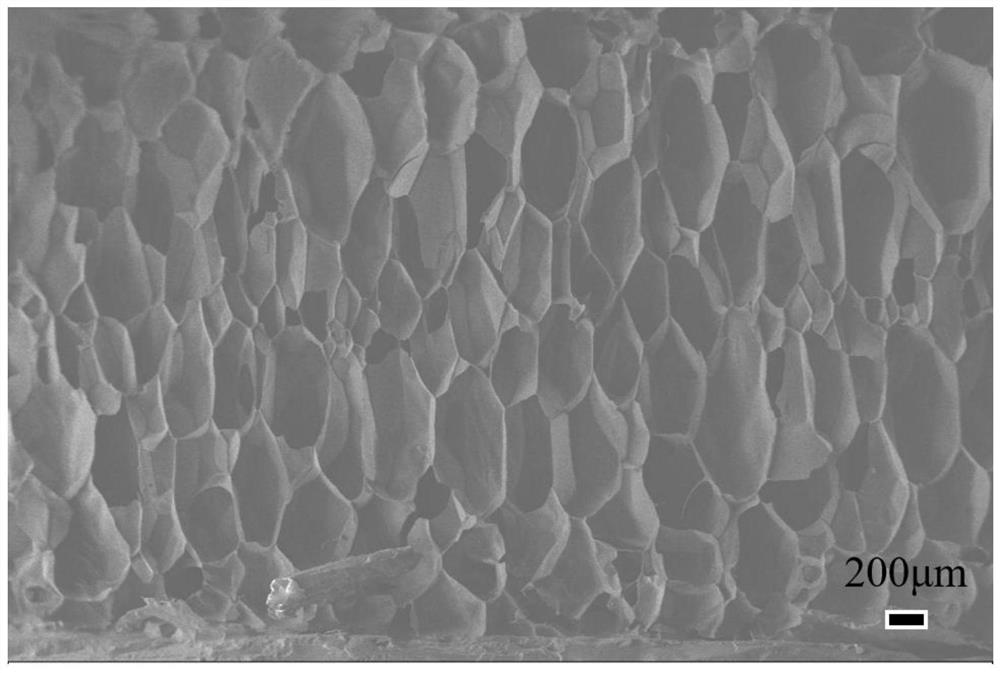

[0029] In the preparation method of the polymer foaming material provided by the present invention, a macromolecular flame retardant is firstly obtained through graft modification, and after blending with the second polymer, not only will it not be as difficult as adding a large amount of small molecule flame retardants or difficult The foaming performance of the second polymer is also seriously affected by the burning filler, and it can be co-foamed with the second polymer to improve the cell structure, so as to obtain a polymer foam with excellent properties such as flame retardancy, heat preservation, sound insulation, and cushioning Material.

[0030] The preparation method of polymer foam material provided by the invention comprises:

[0031] S1, providing a first polymer, mixing the first polymer with a peroxidant and a first solvent, and reacting at a first temperature to obtain a first intermediate product, wherein the main chain of the first polymer contains two key;...

Embodiment 1

[0064] Dissolve butadiene rubber in toluene solvent first, then add peroxyformic acid obtained by mixing 5.81g 88% chemically pure formic acid and 10.49g30% chemically pure hydrogen peroxide, and oxidize butadiene rubber for about 3~ 12h, the reaction solution was obtained. Then use distilled water to wash the reaction solution in a separatory funnel, separate unreacted formic acid and hydrogen peroxide, and then use ethanol precipitation to precipitate the epoxidized butadiene rubber in the reaction solution, and dry it to obtain the first intermediate product epoxy Butadiene rubber, wherein the molar ratio of the double bond in the main chain of the epoxidized butadiene rubber to the epoxy group is 5:5.

[0065] The above-mentioned epoxidized butadiene rubber was dissolved in the organic solvent xylene, 21.6 g of DOPO powder was added, the temperature was raised to 140° C., and the reaction was carried out at constant temperature for 12 hours. Then 13.4 g of polyaniline was...

Embodiment 2

[0068] The only difference between Example 2 and Example 1 is that the mass ratio of macromolecule flame retardant to polylactic acid is 20:80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com