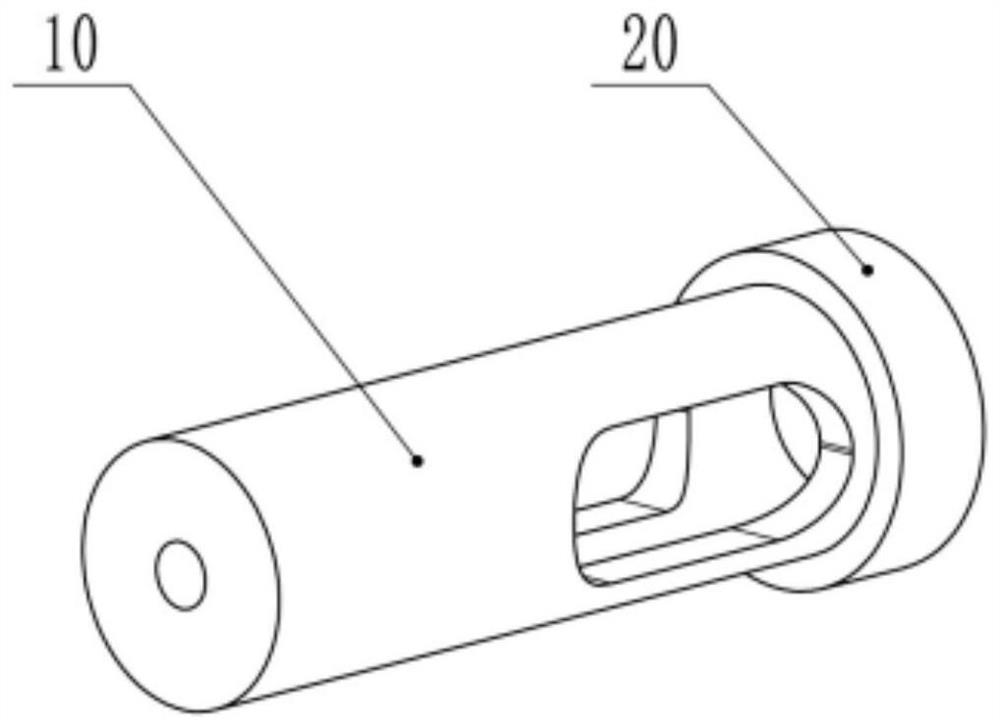

Method for measuring humidity of cable by two-way infrared spectrum analysis method

A technology of infrared spectroscopy and measuring cables, which is applied in the direction of material analysis, measuring devices, and analyzing materials through optical means. It can solve the problems of complex process, expensive equipment, and high cost, and achieve good sensitivity, excellent linear relationship, and sensitive response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Take a clean watch glass, put it into deionized water, dissolve the graphene oxide powder in deionized water, and disperse it with ultrasonic waves for 2 hours to prepare a 2.5% graphene oxide dispersion;

[0042] 2) Dip the PTFE tip into the above-prepared graphene oxide dispersion, hang it vertically with the head down, and put it in a drying oven at 30°C for about half an hour without wind;

[0043] 3) Use an electron microscope to check the graphene oxide attached to the surface of the matrix resin. If it is fully covered, it is qualified. If it is not fully covered, the operation can be repeated;

Embodiment 2

[0045] 1) Cut Ni-Fe-based graphene oxide into 2mm-3mm squares, take a clean watch glass, and put it into electronic grade 60% FeCl 3 Solution, put the above square into the corrosion solution, make it float on the surface, accelerate the corrosion, after 3 hours of corrosion, it can be observed that the Ni-Fe base falls off, transfer the graphene oxide to deionized water with a silicon dioxide substrate and soak After more than 12 hours, the graphene oxide material is prepared; the concentration of graphene oxide in deionized water is 2%.

[0046] 2) Use the end of polytetrafluoroethylene to transfer the graphene oxide to the end of the matrix resin from underwater, and put it in a drying oven at 30°C for about half an hour without wind;

[0047] 3) Use an electron microscope to check the graphene oxide attached to the surface of the matrix resin, and it is qualified if it is completely covered.

Embodiment 3

[0049] 1) Preparation of anionic assembly: 85 mg of graphene oxide was dispersed in 50 mL of water and MDF in a mixed solvent with a mass ratio of 1:2, and mixed evenly to obtain a graphene oxide dispersion, and 4.5 g of methacrylic acid and 0.5g of isobornyl acrylate, slowly drop 0.1g of 10% ethyl acetate solution of azobisisobutyronitrile under a nitrogen atmosphere, react at 60°C for 4h, after the reaction, adjust the pH with 10% sodium bicarbonate to 9. Centrifuge 3 times, add deionized water each time, and finally dilute with deionized water, obtain a dispersion of graphene oxide-polyacrylic acid composite after ultrasonication, and the concentration of graphene oxide in the dispersion is about 0.31wt%.

[0050] 2) Preparation of cationic assembly: In 180mL isopropanol and butyl acetate mixed solvent with a volume ratio of 1:1, add 10g butyl acrylate, 7g hexafluorobutyl acrylate, 6g dimethylaminoethyl acrylate, 2.7g For 4-hydroxybutyl acrylate, slowly add 2.8g of 10% ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com