Preparation method and application of plastic net for capturing dust by utilizing static electricity

An electrostatic and plastic technology, applied in the field of plastic mesh preparation, can solve problems such as insufficient dust adsorption capacity, and achieve the effects of uniform and stable electrostatic charge distribution, strong adsorption capacity, and strong dust adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

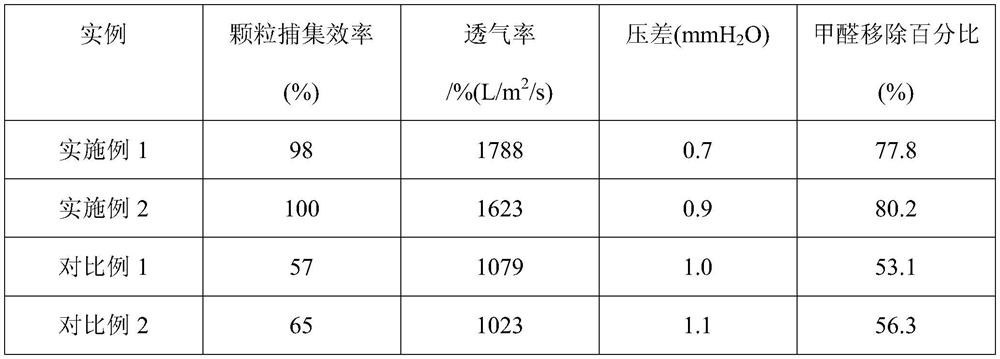

Examples

Embodiment 1

[0020] The preparation method of the plastic net that utilizes static electricity to capture dust described in the embodiment of the present invention comprises the following steps:

[0021] After the PE raw material is dried at 80°C for 2 hours, it is mixed with tourmaline electrostatic additive masterbatch accounting for 4% by weight of the raw material and fed into the screw extruder to be heated and melted in five zones. The heating and melting temperature is: 180°C in the first zone, The second zone is 200°C, the third zone is 240°C, the fourth zone is 270°C, and the fifth zone is 270°C. After that, it is drawn through the spinning die and enters the cold water tank to cool down and form. After that, it is stretched in hot water at a temperature of 90°C by a set of drawing devices for 5 After doubling, collect the bundles and wind them on the pan head, place the pan head frame and arrange the wires evenly, and then enter the warp knitting machine (5, 6, 7, 8, 9 needles) fo...

Embodiment 2

[0025] The preparation method of the plastic net that utilizes static electricity to capture dust described in the embodiment of the present invention comprises the following steps:

[0026] After the PET raw material is dried at 160°C for 4 hours, it is mixed with inorganic salt electrostatic additive masterbatch accounting for 5% by weight of the raw material and fed into the screw extruder to be heated and melted in five zones. The heating and melting temperature is: 1 zone 200°C, The second zone is 230°C, the third zone is 280°C, the fourth zone is 300°C, and the fifth zone is 300°C. Then it is drawn through the spinning die and enters the cold water tank to cool down and form. After that, it is stretched in hot water at a temperature of 95°C by a set of drawing devices for 6 After doubling, collect the bundles and wind them on the pan head, place the pan head frame and arrange the wires evenly, and then enter the warp knitting machine (5, 6, 7, 8, 9 needles) for weaving, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com