A kind of zein/titanium dioxide composite film and its preparation method and application

A zein, nano-titanium dioxide technology, applied in transportation and packaging, packaging, wrapping paper, etc., can solve the problems of aggravating the deterioration of the environment, slow degradation rate, etc., to increase commercial value, improve film structure, and enhance mechanical properties. and barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] The third embodiment of the present invention provides an application of the above-mentioned zein / titanium dioxide composite film in packaging and / or replacing traditional plastic products.

[0047] In order to enable those skilled in the art to understand the technical solution of the present invention more clearly, the technical solution of the present invention will be described in detail below in conjunction with specific embodiments.

[0048] Material:

[0049] Zein (99%, molecular weight 164.2KDa), eugenol and nano-titanium dioxide (99.8%, 25nm, anatase) were purchased from Shanghai McLean Biochemical Technology Co., Ltd. Ethanol, glycerol and Tween 20 were purchased from Sinopharm Group Chemical Reagents Ltd.

[0050] Performance test method:

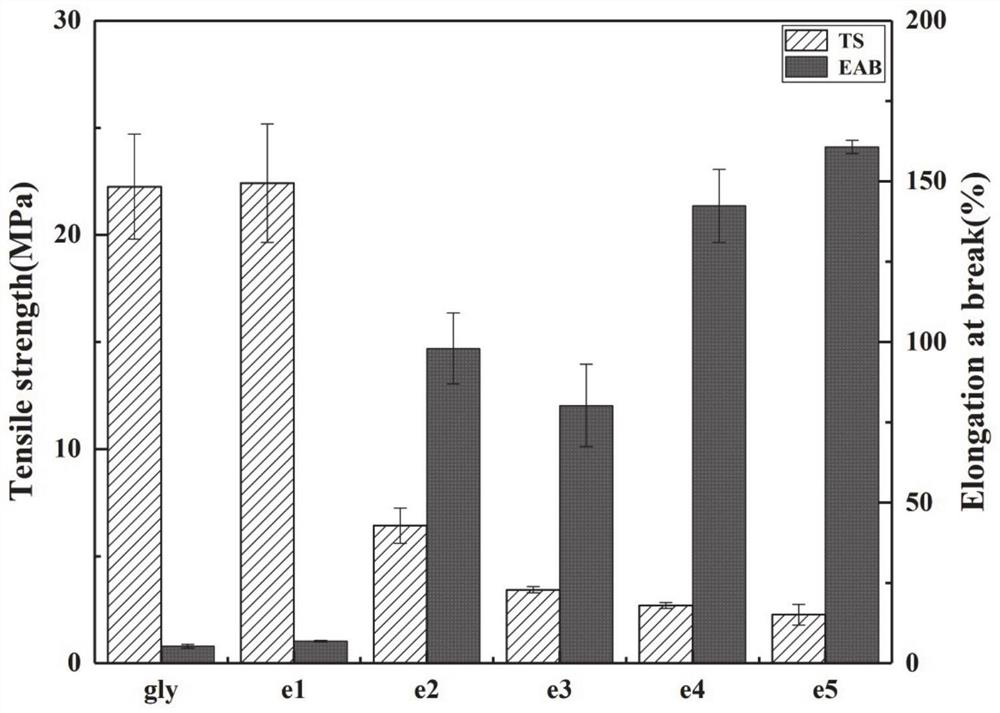

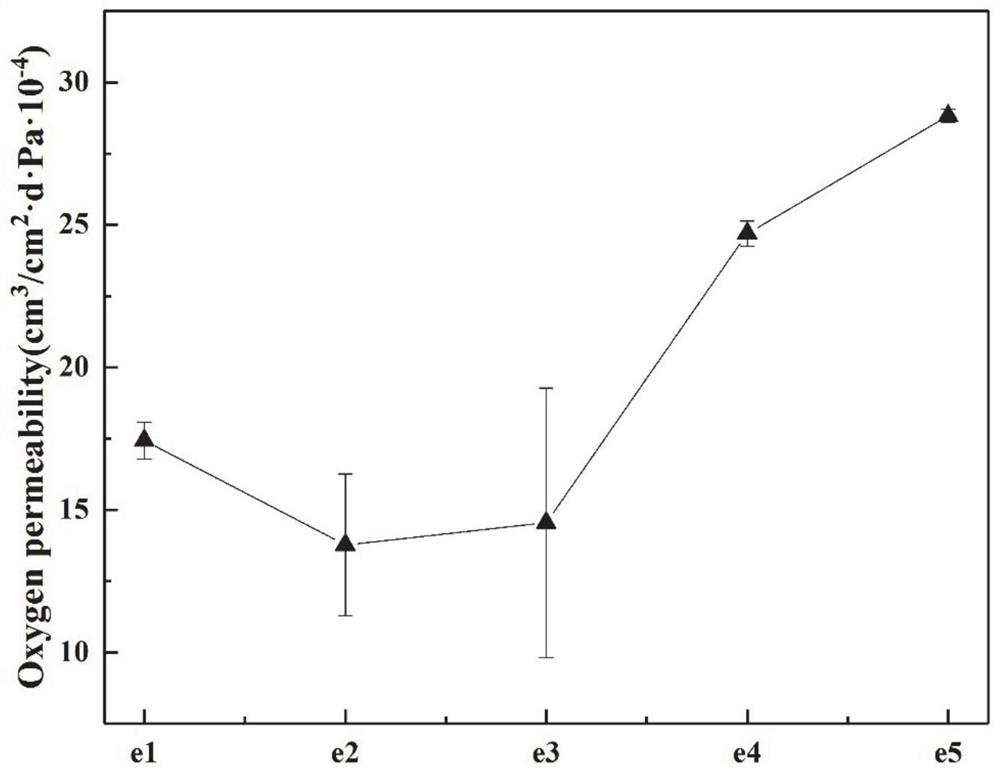

[0051] (1) Tensile performance test

[0052] The tensile properties were evaluated according to ASTM standard method D882 with ZQ-990LA electric tensile and compression testing machine (ZQ, Dongguan). Tensile propertie...

Embodiment 1

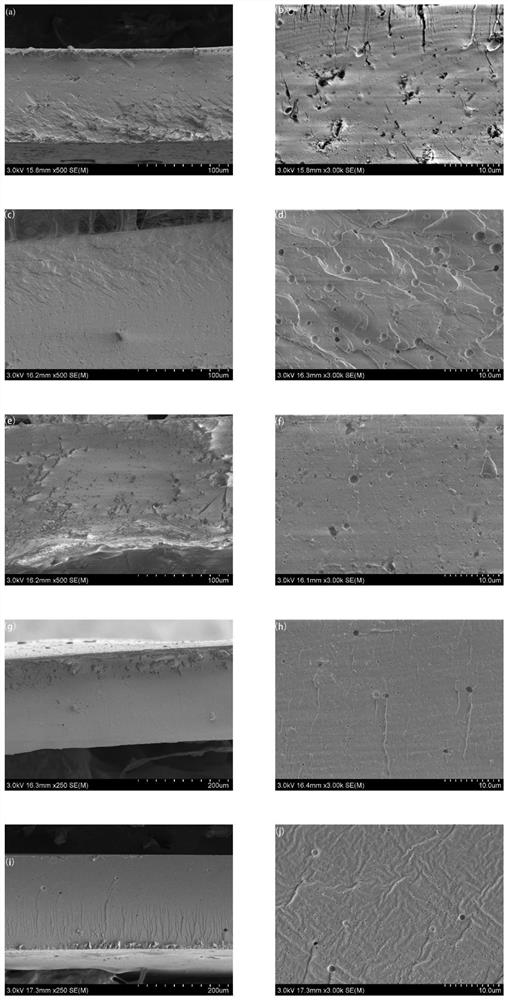

[0072] Embodiment 1: the optimization of ethanol volume fraction

[0073] (1) Use deionized water as a solvent to prepare aqueous ethanol solutions with a volume fraction of 70%, 80%, and 90% v / v in a beaker, and add zein powder to the above-mentioned aqueous ethanol solutions until the solid-to-liquid ratio is 1 : 10g / ml, stir magnetically at room temperature until it dissolves completely.

[0074] (2) Take out the beaker, add 30wt.% glycerol accounting for the mass fraction of zein, and continue magnetic stirring until it is fully mixed.

[0075] (3) The fully mixed dispersion was reacted in a magnetic stirrer at 80°C for 30 minutes while stirring.

[0076] (4) After the reaction, the beaker was taken out, cooled to room temperature, and then the film-forming solution was poured into a square petri dish. Preheat the blast drying oven to 50°C, and place the culture dish in the drying oven to dry for 3 hours.

[0077] (5) The dried film was cooled to room temperature, gentl...

Embodiment 2

[0081] Embodiment 2: Optimization of solid-to-liquid ratio of zein dispersion liquid

[0082] (1) Use deionized water as a solvent to prepare an aqueous ethanol solution with a volume fraction of 80% in a beaker, and add zein powder to the above-mentioned aqueous ethanol solution until the solid-to-liquid ratio is 1:10, 1:20, and 1:1. 40. 1:70g / ml, stir magnetically at room temperature until it is completely dissolved.

[0083] (2) Take out the beaker, add glycerin which accounts for 30% of the mass fraction of zein, and continue magnetic stirring until they are fully mixed.

[0084] (3) The fully mixed dispersion was reacted in a magnetic stirrer at 80°C for 30 minutes while stirring.

[0085] (4) After the reaction, the beaker was taken out, cooled to room temperature, and then the film-forming solution was poured into a square petri dish. Preheat the blast drying oven to 50°C, and place the culture dish in the drying oven to dry for 3 hours.

[0086] (5) The dried film w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com