Super-hard material curved surface grinding and polishing machining device

A superhard material and processing device technology, applied in the direction of grinding devices, grinding drive devices, grinding tools, etc., can solve the problems of difficult processing, short service life of processing tools, and failure to effectively guarantee the yield and performance , to achieve the effects of improving processing efficiency, improving surface processing quality, and improving the precision of machine tool components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

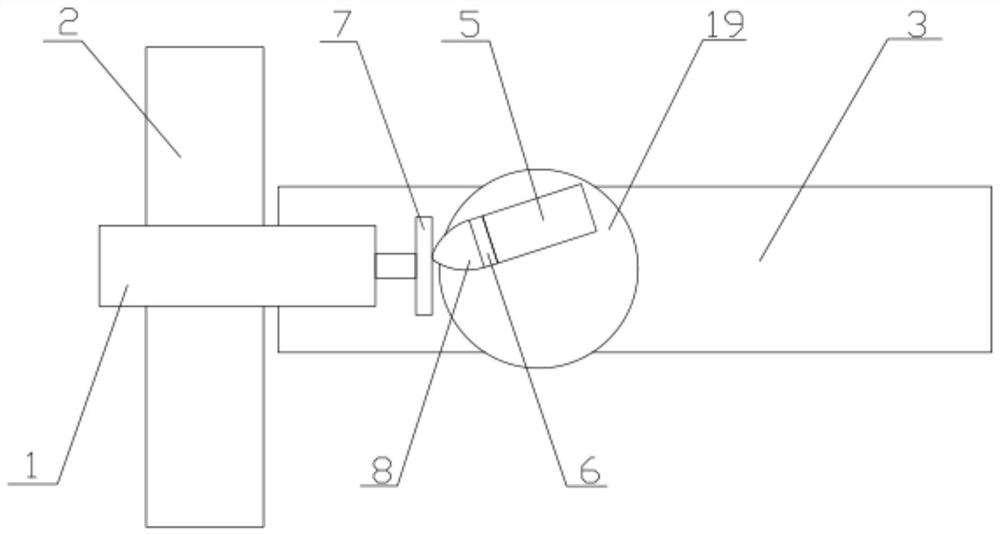

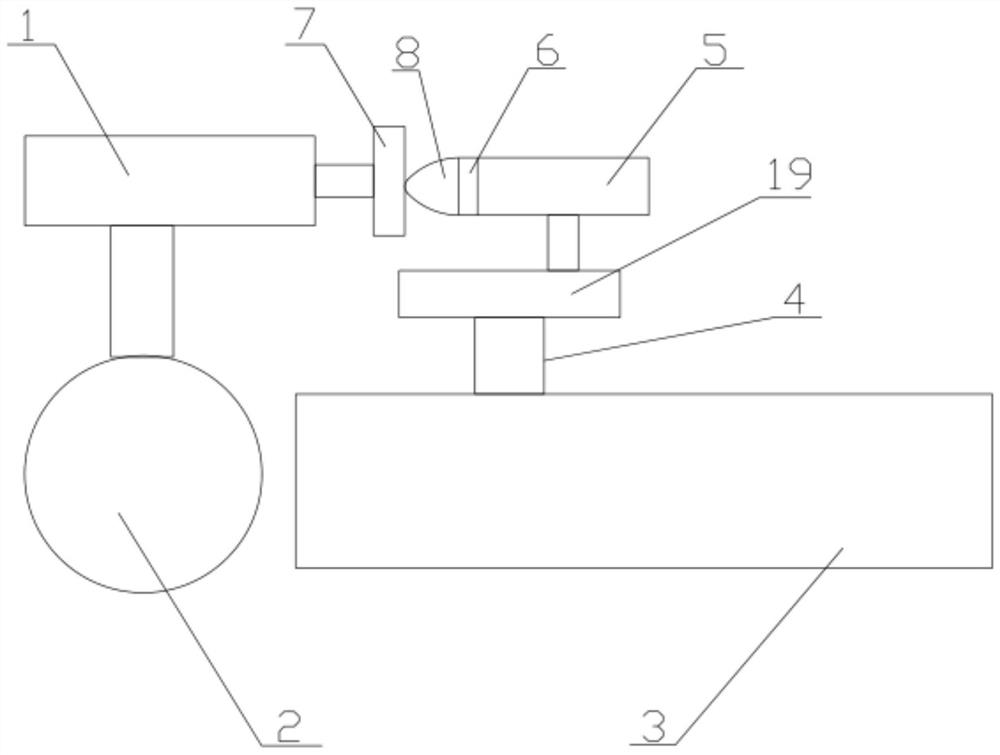

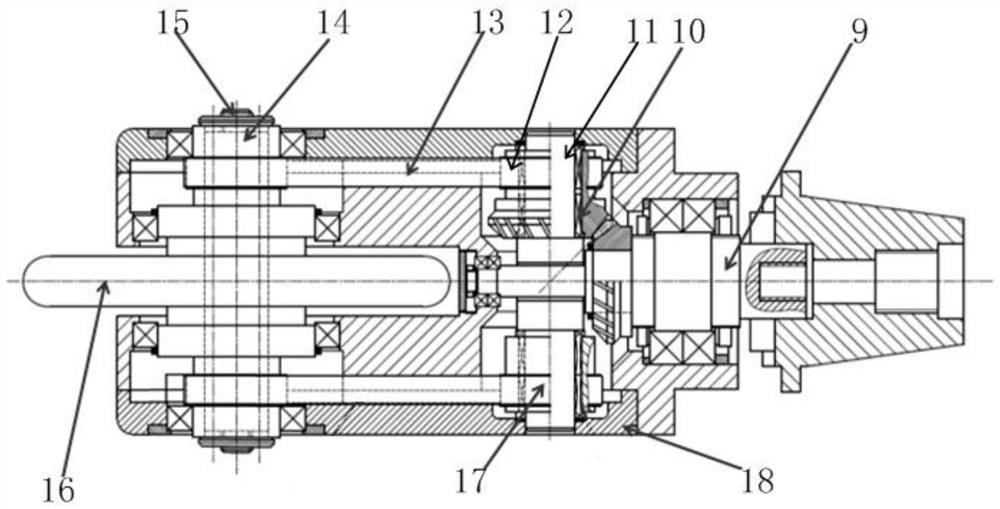

[0033] Such as figure 1 , figure 2 As shown, the superhard material curved surface grinding and polishing processing device includes a first feed shaft 3, a second feed shaft 2, a first rotary shaft 1, a second rotary shaft 4, a third rotary shaft 5, a tool 7, and a workpiece holder holding device 6 and connecting plate 19; wherein, one end of the first rotary shaft 1 is coaxially connected with a cutter 7, and the cutter 7 is a grinding wheel, and the first rotary shaft 1 is slidingly connected with the second feed shaft 2, and by driving the second feed Shaft 2 enables the first rotary shaft 1 to reciprocate axially along the second feed shaft 2; the first feed shaft 3 is arranged perpendicular to the axis of the second feed shaft 2; Sliding connection, by driving the first feed shaft 3 to make the second rotary shaft 4 reciprocate axially along the first feed shaft 3; the third rotary shaft 5 is perpendicular to the axis of the second rotary shaft 4 and connected through ...

Embodiment 2

[0036] On the basis of Embodiment 1, the workpiece clamping device 6 is set as a vacuum gripper system, and a cooling liquid device is set near the tool 7 .

[0037] The vacuum gripper system facilitates the disassembly and clamping of the workpiece 8 to be processed, and the cooling liquid device realizes the cooling of the tool 7 and the contact point with the tool 7 .

Embodiment 3

[0039] On the basis of Embodiment 1, the workpiece clamping device 6 is connected to one end of the first rotary shaft 1 , and the tool 7 is connected to one end of the third rotary shaft 5 .

[0040] This solution is suitable for vertical machine tools. At this time, the first rotary shaft 1 should be driven at a low speed when it is working, and the third rotary shaft 5 should be driven at a high speed when it is working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com