P2-phase layered oxide, preparation method and application of P2-phase layered oxide in sodium ion battery

A sodium ion battery and oxide technology, applied in battery electrodes, secondary batteries, active material electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Material preparation and battery assembly

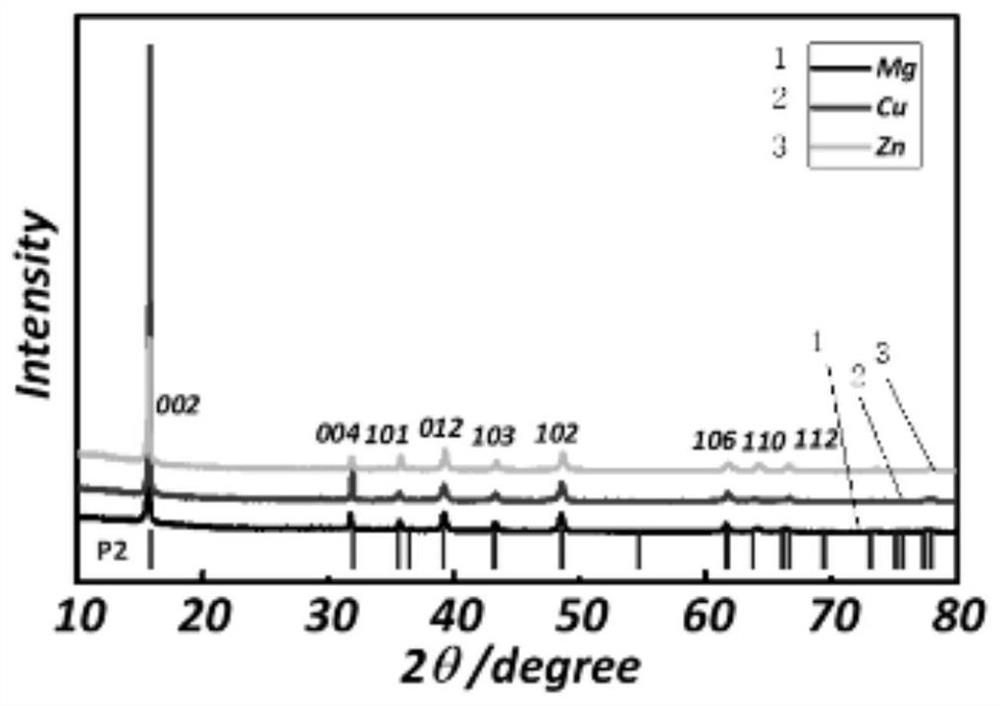

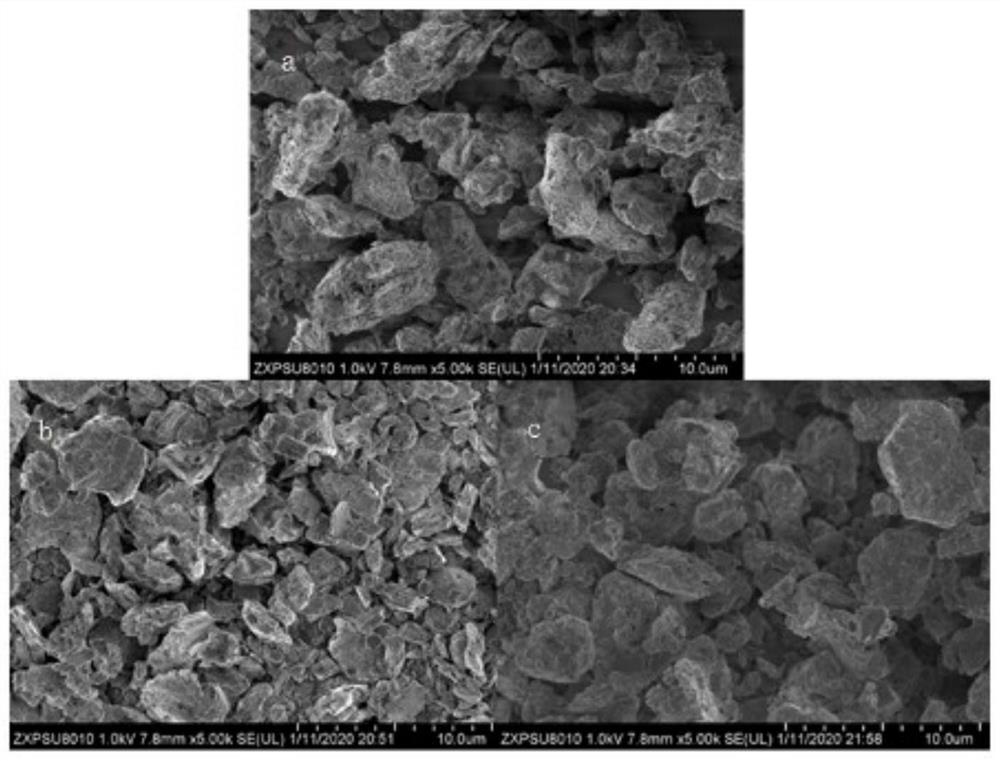

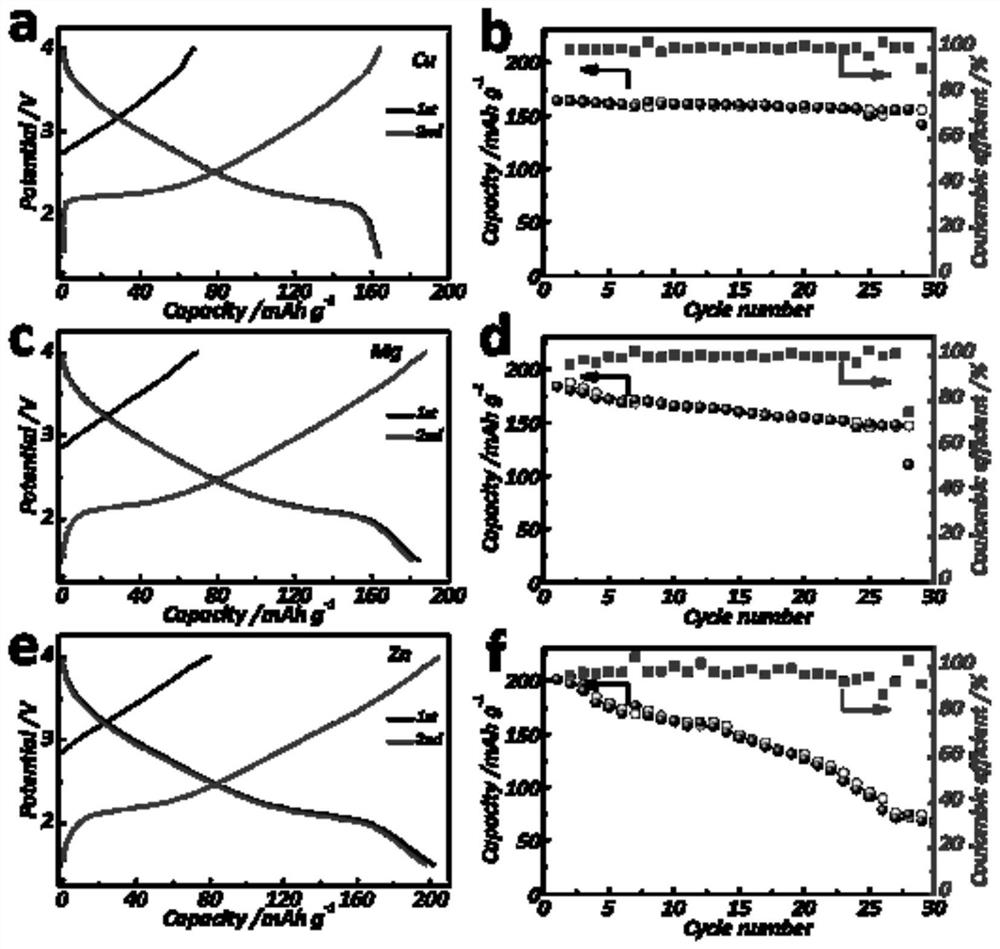

[0061] 1. Material preparation: Na 2 CO 3 (In order to compensate for the loss of sodium at high temperature, Na 2 CO 3 Excess 5wt%), Mn 2 o 3 , CuO(MgO / ZnO), TiO 2 According to a certain stoichiometric ratio, it is added into a ball mill tank, and ball milled for 5 hours at a speed of 300 rpm to fully grind several raw materials and mix them evenly. Then the mixed powder was taken out from the ball mill jar and dried in an oven at 100 °C for 12 h. Take 0.4 g of the dried powder, use a mold with a diameter of 16 mm, press it into tablets, and place it in an alumina crucible. Finally, put the crucible containing the wafer into the tube furnace and heat it at 5°C for min -1 Raise the temperature to 900°C, keep it under an argon / oxygen atmosphere for 15 hours, and then cool it with the furnace until the temperature drops to room temperature, take it out, and grind it to obtain a black-brown powder material.

[0062] 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com