Method for preparing p-coumarate by catalyzing lignin depolymerization through hierarchical pore molecular sieve loaded molybdenum oxide

A coumaric acid ester and molecular sieve technology, which is applied in molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of difficult separation and recycling of catalysts, low lignin conversion rate, harsh reaction conditions, etc. High utilization value, high yield and high selective depolymerization, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

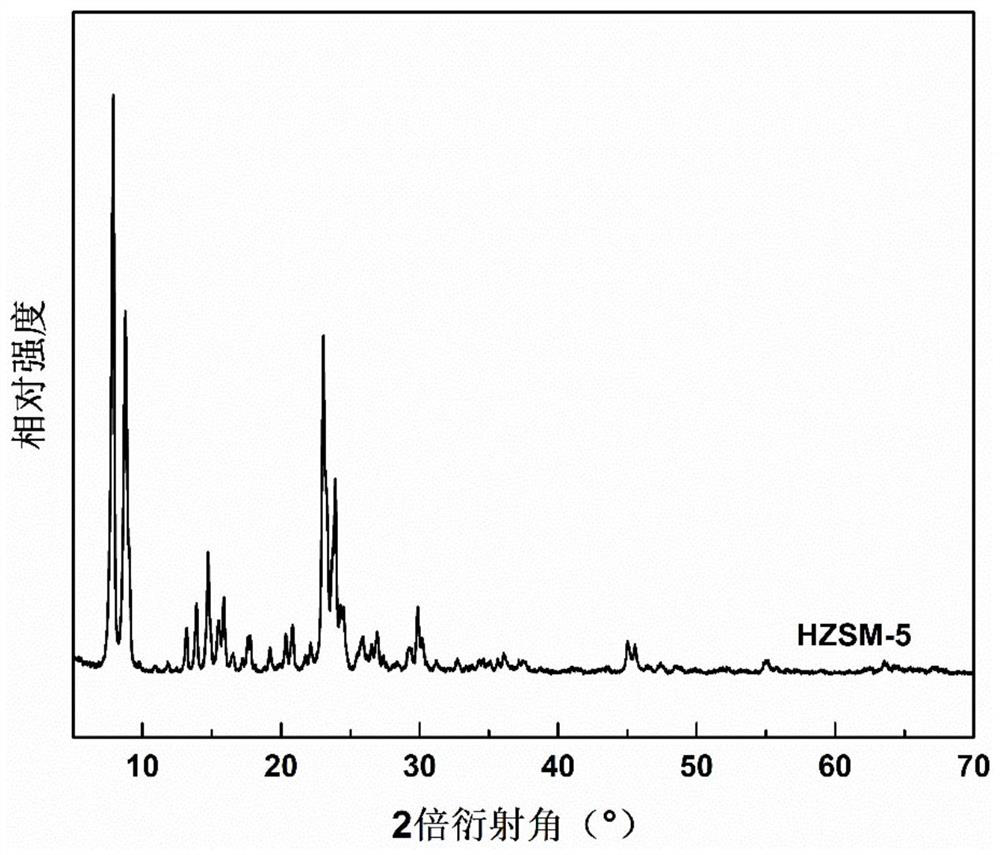

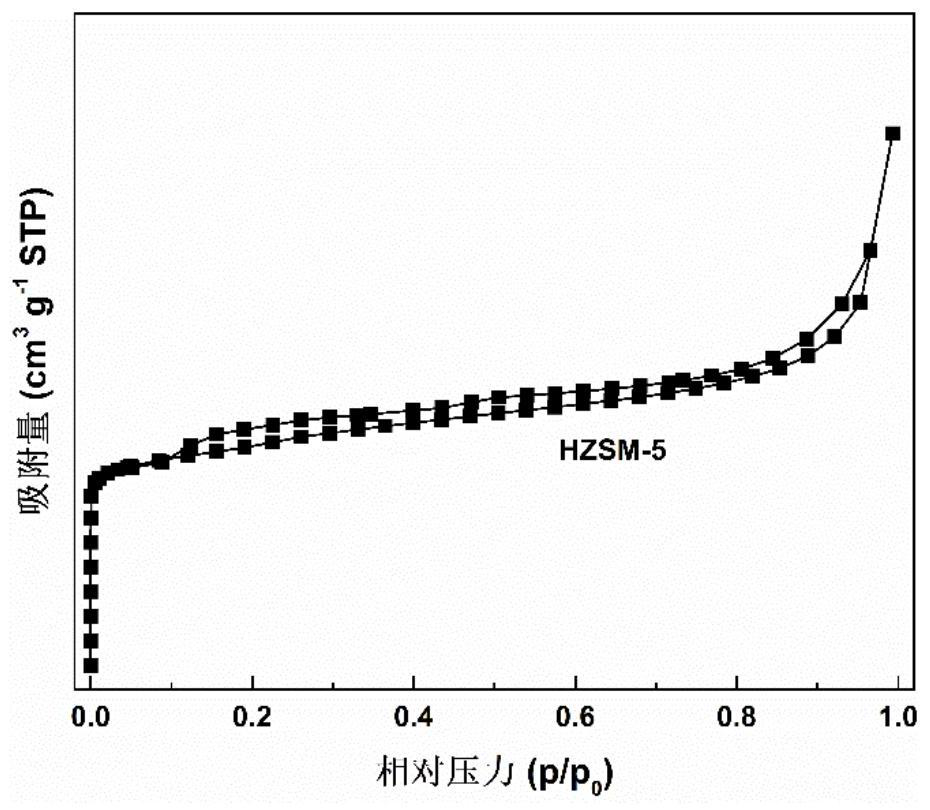

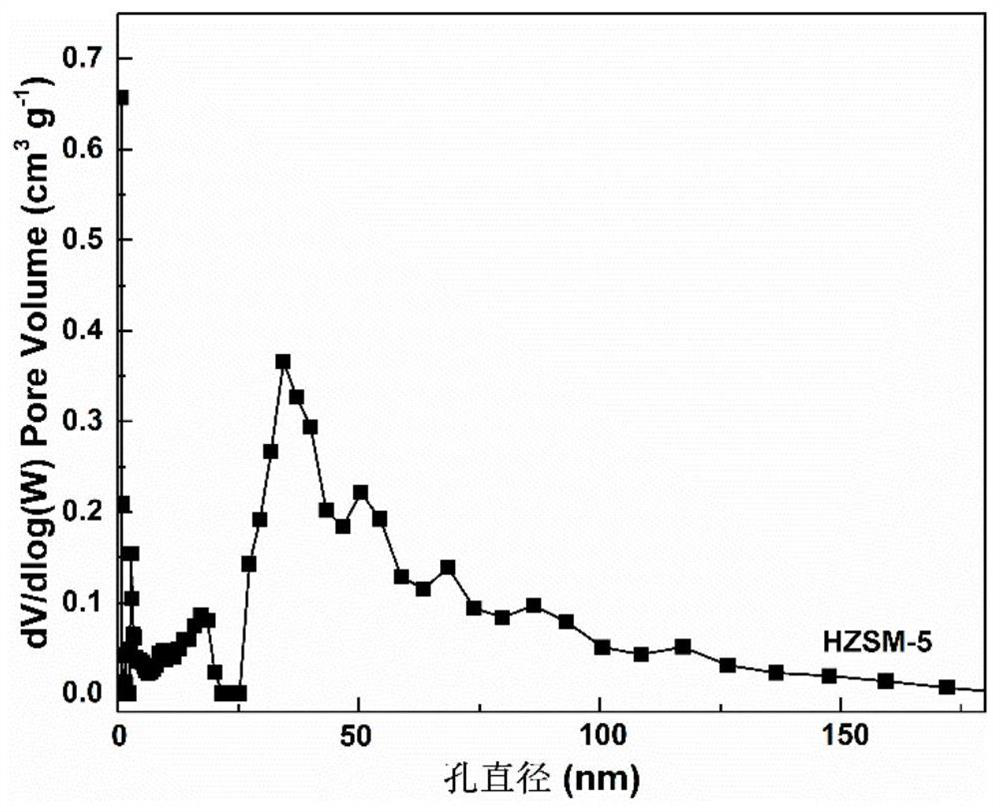

[0039] Embodiment 1: the preparation of 5wt.%Mo / ZSM-5 catalyst

[0040] The preparation of the molybdenum oxide catalyst 5wt.% Mo / ZSM-5 supported by the hierarchical porous molecular sieve is realized by a two-step method:

[0041] (1) Preparation of HZSM-5 carrier: use tetraethylorthosilicate as silicon source, tetrapropylammonium hydroxide as template, sodium metaaluminate as aluminum source, mix silicon source and template, and disperse in In water, stir for 3 hours until the silicon source is completely hydrolyzed, then add amino acid, stir for 2 hours until the dispersion is uniform, and then evaporate the water to the specified water-to-silicon ratio (mol(H 2 O): mol (SiO 2 )=9:1), the molar ratio of each active ingredient is 1.0SiO 2 : 0.003Al 2 o 3 : 0.015Na 2 O: 0.45TPAOH: 0.4L-lysine: 9H 2 The initial gel of O. Put the initial gel into a stainless steel hydrothermal reaction kettle lined with polytetrafluoroethylene, crystallize in an oven at 90°C for 48h, the...

Embodiment 2

[0046] Embodiment 2: the preparation of 2.5wt.%Mo / ZSM-5 catalyst

[0047] The preparation of molybdenum oxide catalyst 2.5wt.%Mo / ZSM-5 supported by hierarchical pore molecular sieves is achieved by a two-step method:

[0048] (1) Preparation of HZSM-5 carrier: use tetraethylorthosilicate as silicon source, tetrapropylammonium hydroxide as template, sodium metaaluminate as aluminum source, mix silicon source and template, and disperse in In water, stir for 6 hours until the silicon source is completely hydrolyzed, then add amino acid, stir for 4 hours to disperse evenly, then evaporate the water to the specified water-to-silicon ratio (mol(H 2 O): mol (SiO 2 )=9:1; ), the molar ratio of each active ingredient obtained is 1.0SiO 2 : 0.003Al 2 o 3: 0.015Na 2 O: 0.45TPAOH: 0.4L-lysine: 9H 2 The initial gel of O. Put the initial gel into a stainless steel hydrothermal reaction kettle with polytetrafluoroethylene lining, crystallize in an oven at 70°C for 60 hours, then move ...

Embodiment 3

[0051] Embodiment 3: the preparation of 10wt.%Mo / ZSM-5 catalyst

[0052] The preparation of the molybdenum oxide catalyst 10wt.% Mo / ZSM-5 supported by the hierarchical porous molecular sieve is realized by a two-step method:

[0053] (1) Preparation of HZSM-5 carrier: use tetraethylorthosilicate as silicon source, tetrapropylammonium hydroxide as template, sodium metaaluminate as aluminum source, mix silicon source and template, and disperse in In water, stir for 3 hours until the silicon source is completely hydrolyzed, then add amino acid, stir for 2 hours until the dispersion is uniform, and then evaporate the water to the specified water-to-silicon ratio (mol(H 2 O): mol (SiO 2 )=9:1; ), the molar ratio of each active ingredient obtained is 1.0SiO 2 : 0.003Al 2 o 3 : 0.015Na 2 O: 0.45TPAOH: 0.4L-lysine: 9H 2 The initial gel of O. Put the initial gel into a stainless steel hydrothermal reaction kettle lined with polytetrafluoroethylene, crystallize in an oven at 90°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com