Copolymerized phosphorus-nitrogen macromolecular expansion flame retardant modified layered nano zirconium phosphate and its preparation method and application

An intumescent flame retardant and layered nanotechnology, applied in the field of zirconium phosphate, can solve the problems of limited flame retardant efficiency, high content of hindered amine groups, and inability to effectively control, and achieve excellent flame retardant performance and thermal stability. Overcoming the effect of easy migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

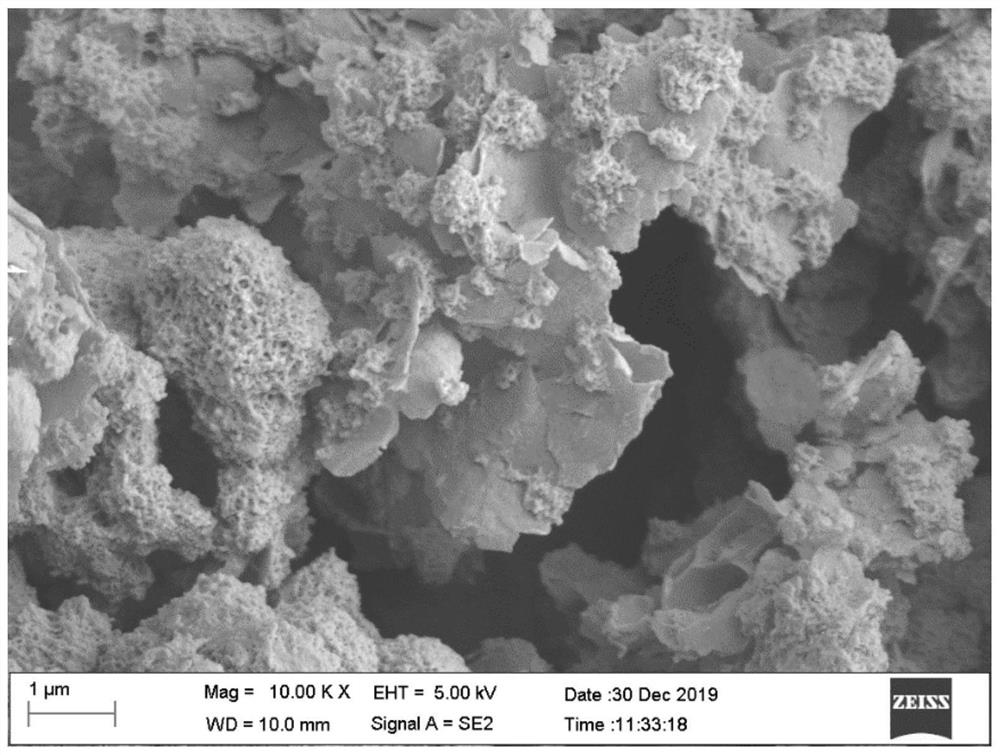

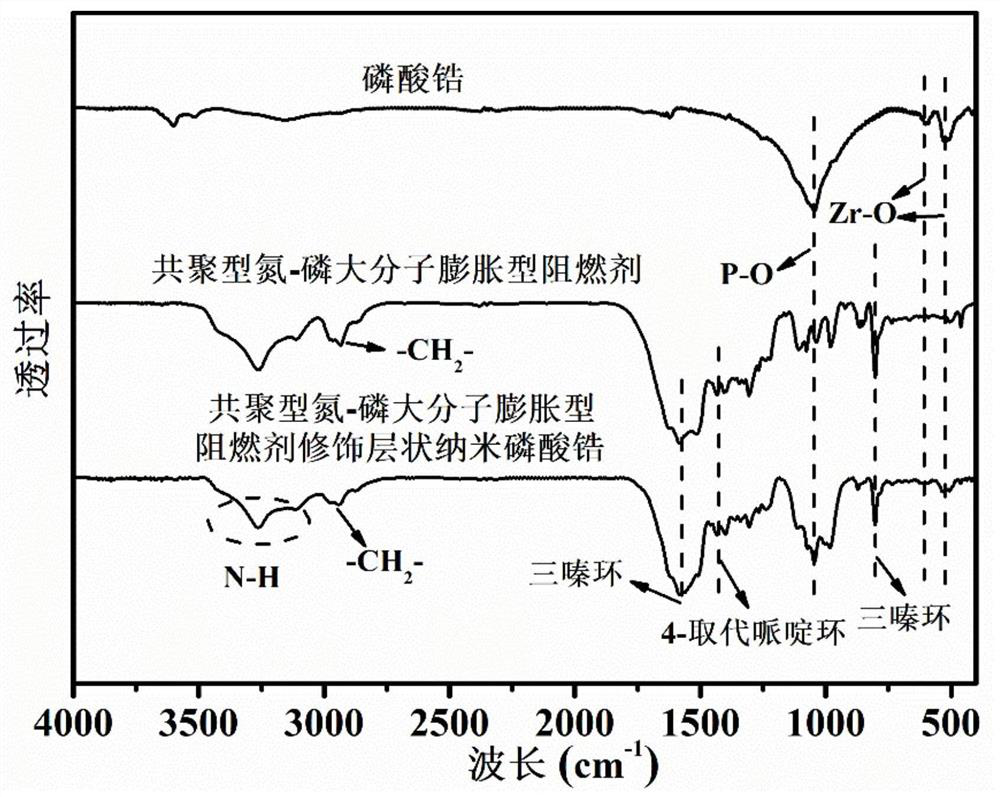

[0035] The preparation method of the layered nano zirconium phosphate modified by the copolymerization type phosphorus-nitrogen macromolecule expansion type flame retardant comprises the following steps:

[0036] 1) Synthesis of copolymerized phosphorus-nitrogen macromolecular intumescent flame retardant: at 5°C, add 36.90g of cyanuric chloride, 35.82g of PEPA, 0.75g of T152 and 250mL of acetonitrile into a 500mL four-neck flask, Stir mechanically for 15 minutes at a speed of 1 / min; slowly add 20.20 g of triethylamine dropwise for 1.5 hours, and continue to react for 4 hours after the dropwise addition is completed; then, continue to dropwise add 12.00 g of ethylenediamine and The mixed solution of 20.20g triethylamine, the dropwise addition time is 1.5h, after the dropwise addition is completed, continue to react for 6h. Finally, the temperature was raised to 95°C, and 20.20 g of triethylamine was added dropwise for reflux reaction for 6 h. After the reaction is finished, th...

Embodiment 2

[0041] The preparation method of the layered nano zirconium phosphate modified by the copolymerization type phosphorus-nitrogen macromolecule expansion type flame retardant comprises the following steps:

[0042] 1) Synthesis of copolymerized nitrogen-phosphorus macromolecular intumescent flame retardant: Add 36.90g of cyanuric chloride, 35.64g of PEPA, 1.50g of T152 and 250mL of toluene into a 500mL four-necked flask at 0°C, Stir mechanically at a speed of 10min / min; slowly add 23.70g of pyridine dropwise for 2h, and continue to react for 5h after the dropwise addition is completed; then, continue to dropwise add 14.40g of ethylenediamine and 15.82g of pyridine after the temperature rises to 60°C The mixed solution, the dropwise addition time is 2h, and the reaction is continued for 8h after the dropwise addition is completed. Finally, the temperature was raised to 100°C, and 23.70 g of pyridine was added dropwise for reflux reaction for 9 hours. After the reaction is finish...

Embodiment 3

[0046] The preparation method of the layered nano zirconium phosphate modified by the copolymerization type phosphorus-nitrogen macromolecule expansion type flame retardant comprises the following steps:

[0047] 1) Synthesis of copolymerized phosphorus-nitrogen macromolecular intumescent flame retardant: Add 36.90g of cyanuric chloride, 35.29g of PEPA, 2.97g of T152 and 250mL of 1,4- Dioxane, stir mechanically at 200r / min to disperse evenly; slowly add 24.24g of triethylamine dropwise for 2h, and continue to react for 3h after the drop; then, continue to A mixture of 12.00 g of ethylenediamine and 24.24 g of triethylamine was added dropwise for 2 hours, and the reaction was continued for 8 hours after the drop was completed. Finally, the temperature was raised to 100°C, and 24.24 g of triethylamine was added dropwise for reflux reaction for 9 h. After the reaction, the mixed liquid is filtered, washed and dried to obtain a macromolecular intumescent flame retardant with adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com