Preparation methods for hyperbranched polyester based phosphorus-nitrogen type flame retardant and flame-retardant fabrics

A technology of hyperbranched polyester and flame retardant, which can be used in flame retardant fibers, plant fibers, textiles and paper making, etc., can solve problems such as residues and life safety threats, achieve low cost, simple preparation process, and realize industrialized production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a phosphorus and nitrogen type green durable flame retardant and flame-retardant fabric of hyperbranched polyester, and the specific preparation steps are as follows:

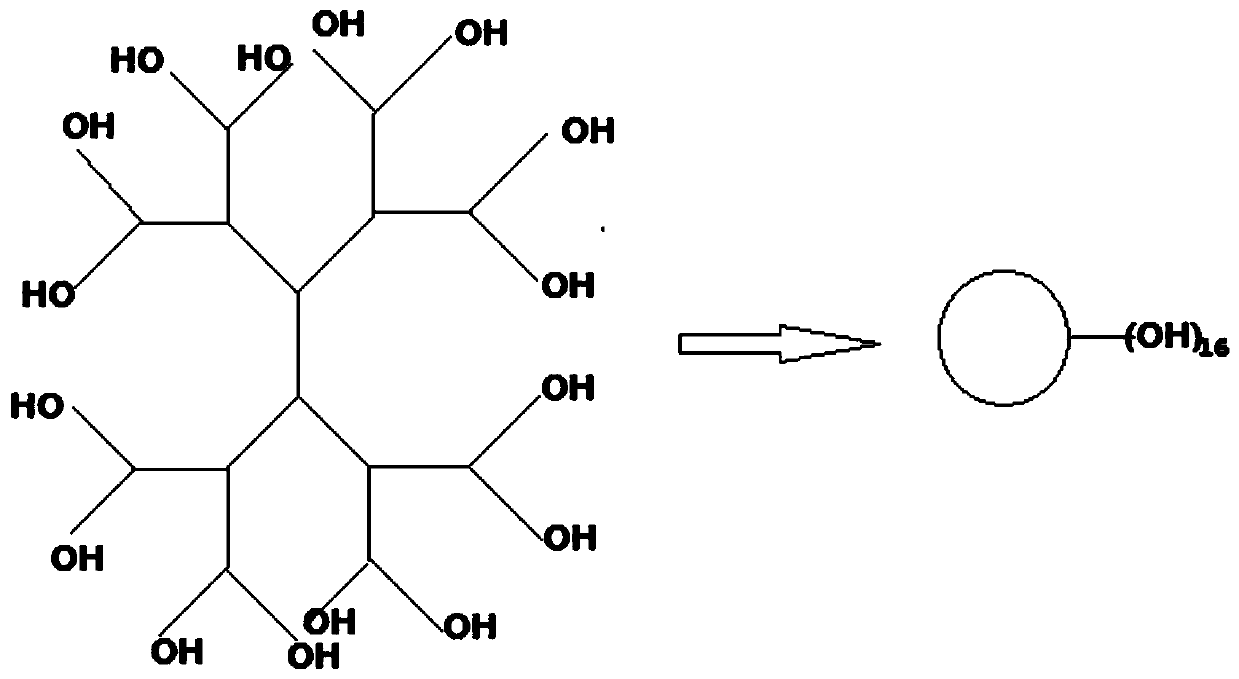

[0030] Step 1: Dissolve 1.0 g of hyperbranched polyester (Boltorn H20 of Seebio) in 49 g of deionized water to make a 2 wt % hyperbranched polyester solution; add 0.8 g of phosphorous acid, the mole of hyperbranched polyester and phosphorous acid The ratio is 1:16, keep stirring, react in a water bath at 70°C for 4 hours, use a dialysis membrane with a molecular weight cut-off of 2000 for dialysis, change the water at 0.5h, 1h, 2h, 4h, 8h, and 12h, and separate and purify Go out phosphorus-containing hyperbranched polyester, dry in the vacuum oven of 50 ℃ for subsequent use;

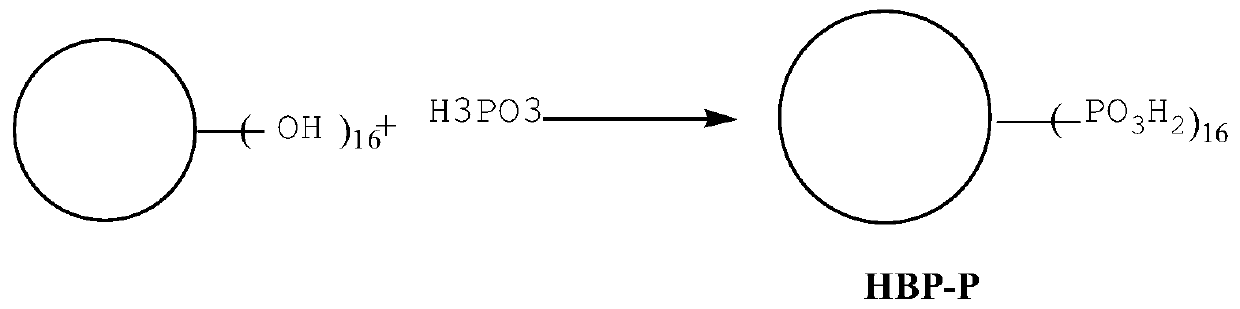

[0031] Step 2: Dissolve 1.0g of phosphorus-containing hyperbranched polyester in deionized water, add 0.6g of urea, the molar ratio of phosphorus-containing hyperbranched polyester to urea is 1:16, condense...

Embodiment 2

[0035] This embodiment provides a phosphorus and nitrogen type green durable flame retardant and flame-retardant fabric of hyperbranched polyester, and the specific preparation steps are as follows:

[0036] Step 1: Dissolve 1.0 g of hyperbranched polyester (Boltorn H20 of Seebio) in 49 g of deionized water to make a 2 wt % hyperbranched polyester solution; add 0.8 g of phosphorous acid, the mole of hyperbranched polyester and phosphorous acid The ratio is 1:16, keep stirring, react in a water bath at 80°C for 4 hours, use a dialysis membrane with a molecular weight cut-off of 2000 for dialysis, change the water at 0.5h, 1h, 2h, 4h, 8h, and 12h, and separate and purify Go out phosphorus-containing hyperbranched polyester, dry in the vacuum oven of 50 ℃ for subsequent use;

[0037] Step 2: Dissolve 1.0g of phosphorus-containing hyperbranched polyester in deionized water, add 0.6g of urea, the molar ratio of phosphorus-containing hyperbranched polyester to urea is 1:16, condense...

Embodiment 3

[0041] This embodiment provides a phosphorus and nitrogen type green durable flame retardant and flame-retardant fabric of hyperbranched polyester, and the specific preparation steps are as follows:

[0042] Step 1: Dissolve 1.0 g of hyperbranched polyester (Boltorn H20 of Seebio) in 49 g of deionized water to make a 2 wt % hyperbranched polyester solution; add 0.8 g of phosphorous acid, the mole of hyperbranched polyester and phosphorous acid The ratio is 1:16, keep stirring, react in a water bath at 80°C for 1 hour, use a dialysis membrane with a molecular weight cut-off of 2000 for dialysis, change the water at 0.5 hours, 1 hour, 2 hours, 4 hours, 8 hours, and 12 hours, separate and purify Go out phosphorus-containing hyperbranched polyester, dry in the vacuum oven of 50 ℃ for subsequent use;

[0043] Step 2: Dissolve 1.0g of phosphorus-containing hyperbranched polyester in deionized water, add 0.6g of urea, the molar ratio of phosphorus-containing hyperbranched polyester t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com