Acrylate copolymer, preparation method and application thereof

A technology of acrylate and copolymer, which is applied in the field of polymers, can solve the problems of easy hydrolysis, inability to realize environmental protection, flame retardancy, easy migration, etc., and achieve the effect of good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

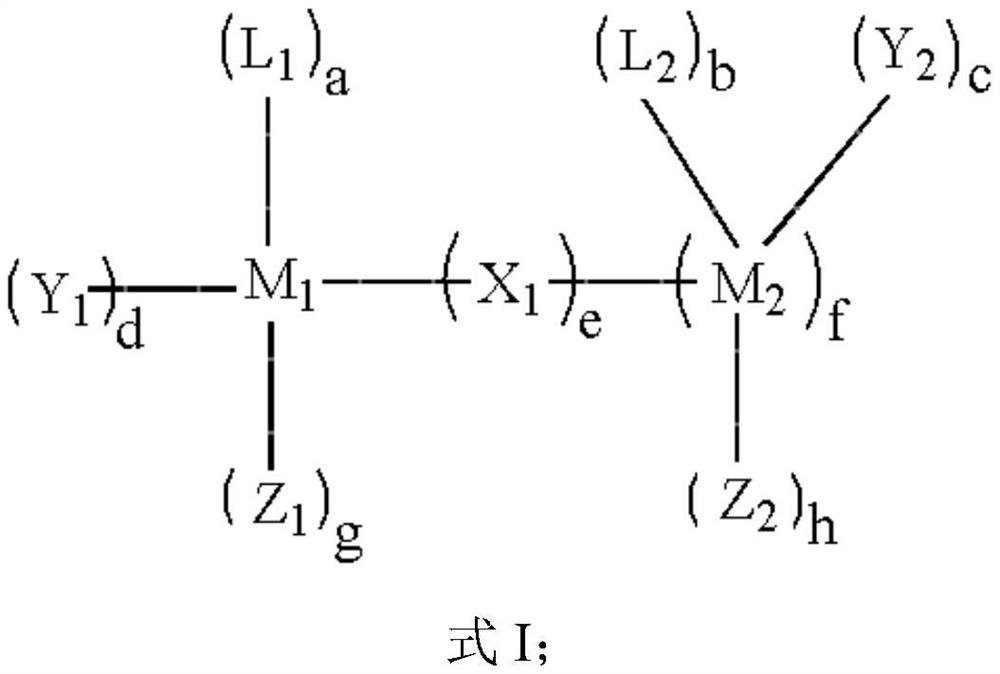

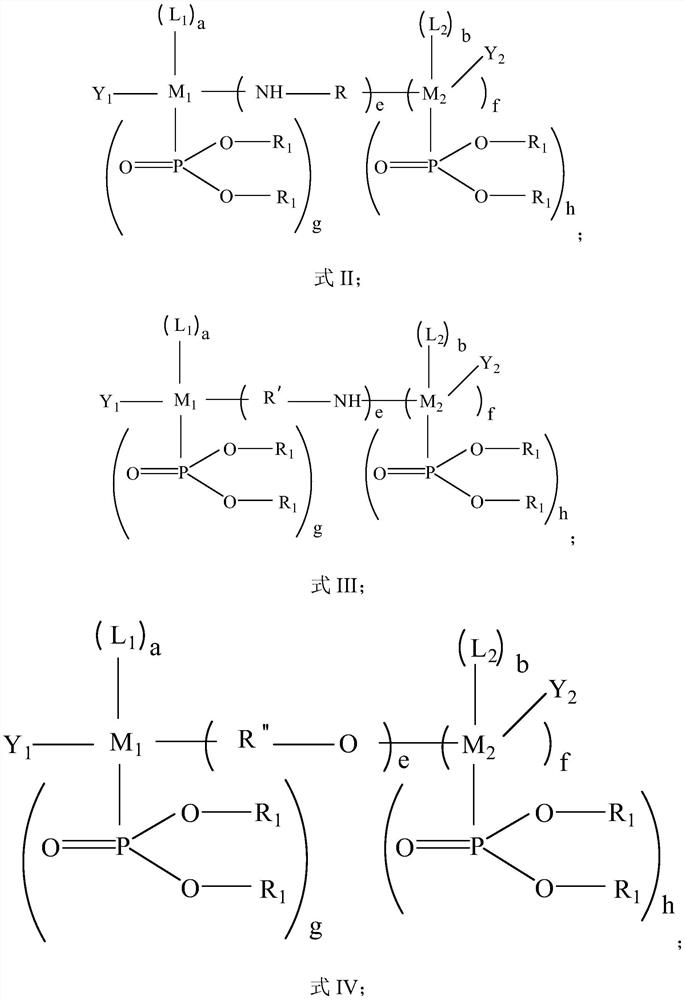

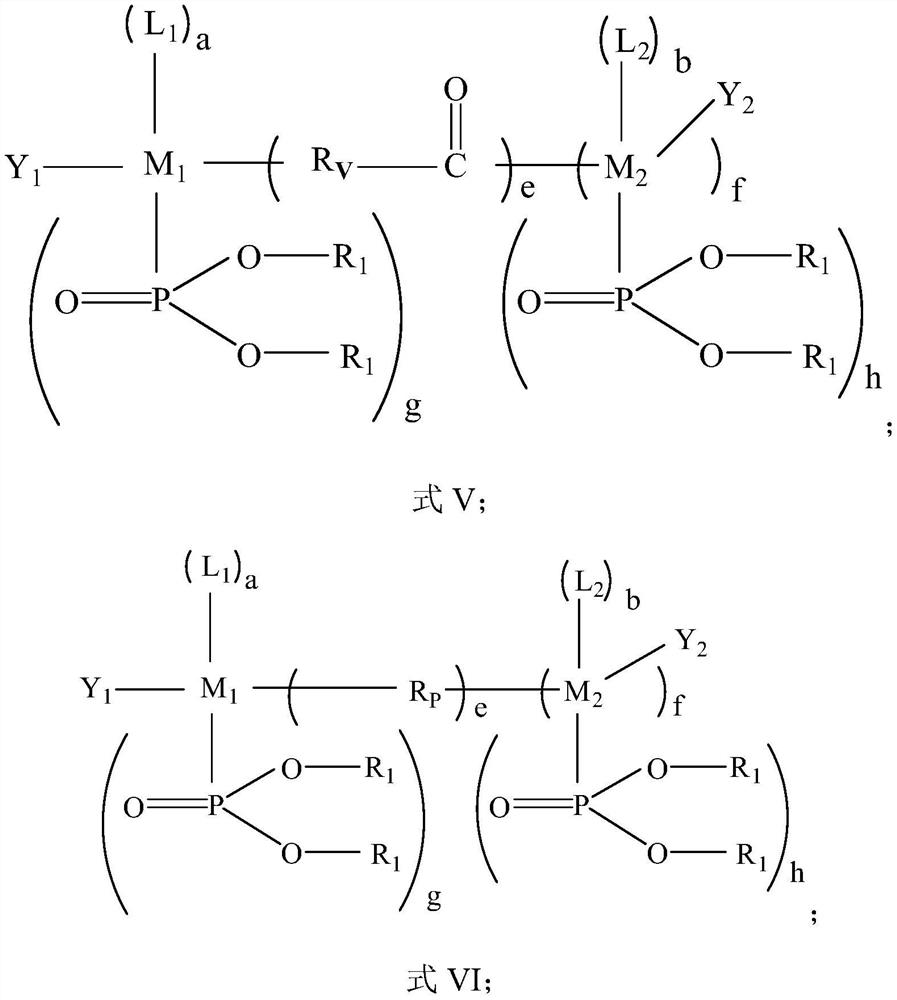

Method used

Image

Examples

preparation example 1

[0088] A phosphorus-containing flame retardant with a vinyl group, the structure is as follows:

[0089]

[0090] Acryloyl chloride (purity 95%, 0.91g, 10mmol) of toluene (2mL) solution was reacted for 30min, then added 5mL of toluene, stirred at room temperature for 2h, and terminated the reaction by adding 10mL of water, the organic phase was extracted with diethyl ether, dried with magnesium sulfate, and The solvent was stripped off under vacuum to obtain a pale yellow solid.

[0091] 1 H NMR (CDCl 3 , 400MHz, TMS): δ=7.78(s, 1H, -CO-NH-), 7.50-7.70(dd, 2H, -C 6 h 4 -), 7.10-7.30 (dd, 2H, -C 6 h 4 -), 6.40-6.50 (m, 1H, -CH=), 5.60-6.00 (dd, 2H, -CH=), 3.95-4.08 (m, 4H, -O-CH 2 -), 3.07-3.14(s, 2H, -C 6 h 4 -C H 2 -), 1.20-1.40 (t, 6H, -CH 2 -C H 3 ).

preparation example 2

[0093] A phosphorus-containing flame retardant with a vinyl group, the structure is as follows:

[0094]

[0095] To a solution of diethyl 4-(amino)benzylphosphonate (1.94 g, 8 mmol) and triethylamine (0.87 g, 8.6 mmol) in toluene (7 mL) cooled to 0-5 °C was added dropwise methacryloyl chloride (0.9g, 8.6mmol) in toluene (9mL) was reacted for 30min, then 5mL of toluene was added, stirred at room temperature for 2h, and the reaction was terminated by adding 10mL of water, the organic phase was extracted with diethyl ether, dried with magnesium sulfate, and The solvent was stripped off under conditions to obtain a light yellow solid.

[0096] 1 H NMR (CDCl 3 , 400MHz, TMS): δ=7.80-7.90 (s, 1H, -CO-NH-), 7.50-7.70 (dd, 2H, -C 6 h 4 -), 7.10-7.30 (dd, 2H, -C 6 h 4 -), 5.80-5.90 (s, 1H, -CH=), 5.40-5.50 (s, 1H, -CH=), 3.95-4.08 (m, 4H, -O-CH 2 -), 3.07-3.18(s, 2H, -C 6 h 4 -C H 2 -), 2.00-2.20 (s, 3H, =C-CH 3 ), 1.20-1.40 (t, 6H, -CH 2 -C H 3 ).

preparation example 3

[0098] A phosphorus-containing flame retardant with a vinyl group, the structure is as follows:

[0099]

[0100] The preparation method is as follows:

[0101] Add 1 mol of diethyl phosphite and 1 mol of acrolein into a three-necked flask equipped with magnetic stirring and a thermometer. Under stirring, control the temperature in an ice-water bath below 5°C, add 1 mol of triethylamine dropwise, gradually raise the temperature to 50°C, and continue After reacting for 0.5h, the phosphorus-containing flame retardant of the above structure was obtained by distillation under reduced pressure.

[0102] 1 H NMR (400MHz, DMSO-d6): δ=5.86-5.90 (m, 1H, =CH-), 5.27-5.39 (m, 2H, CH 2 =), 5.10-5.12 (m, 1H, -OH), 4.15-4.22 (m, 1H, -CH-), 3.87-4.02 (m, 4H, -CH 2 -), 1.24-1.28(t, 6H, -CH 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com