Material for processing optical element and preparation method thereof

A technology of optical components and raw materials, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of increased PV value of optical glass mirror surface shape accuracy, and reduce curing The effect of speed and curing stress, low viscosity and high solvent ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of above-mentioned optical element processing material, the method concrete steps are as follows:

[0019] Add the above-mentioned components into the stainless steel reaction kettle in sequence according to the amount, heat at 65-75°C, and stir evenly under the protection of nitrogen to obtain the adhesive for polishing and fixing the ground glass.

Embodiment 1

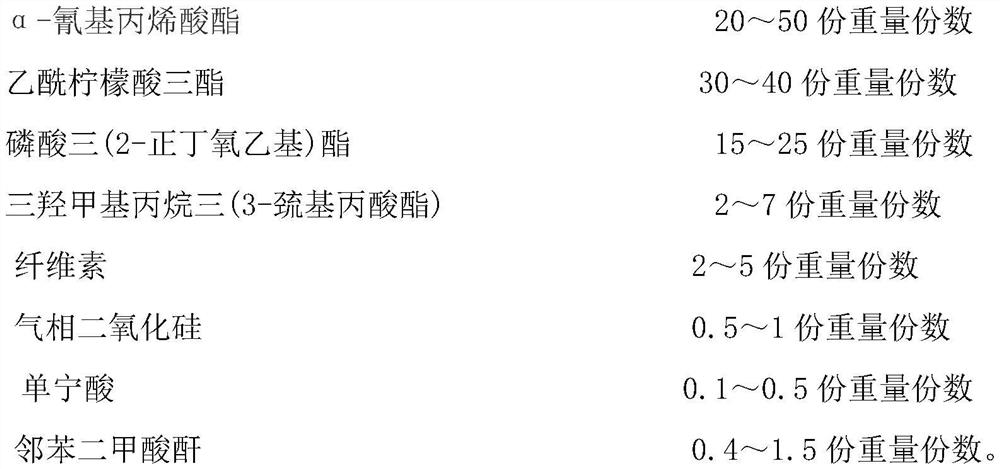

[0027]

[0028] Add the above-mentioned components into a stainless steel reaction kettle in sequence according to the amount, heat at 65° C., and stir evenly under nitrogen protection to obtain the material for optical element processing. Set up 5 groups according to embodiment, its performance is shown in Table 1:

[0029] Table 1.

[0030] serial number Tensile shear strength (MPa) Degumming time (hours) PV value (λ) 1 11.5 4.6 0.07 2 11.0 4.3 0.08 3 10.6 5.2 0.07 4 10.2 6.2 0.04 5 10.6 6.0 0.05

Embodiment 2

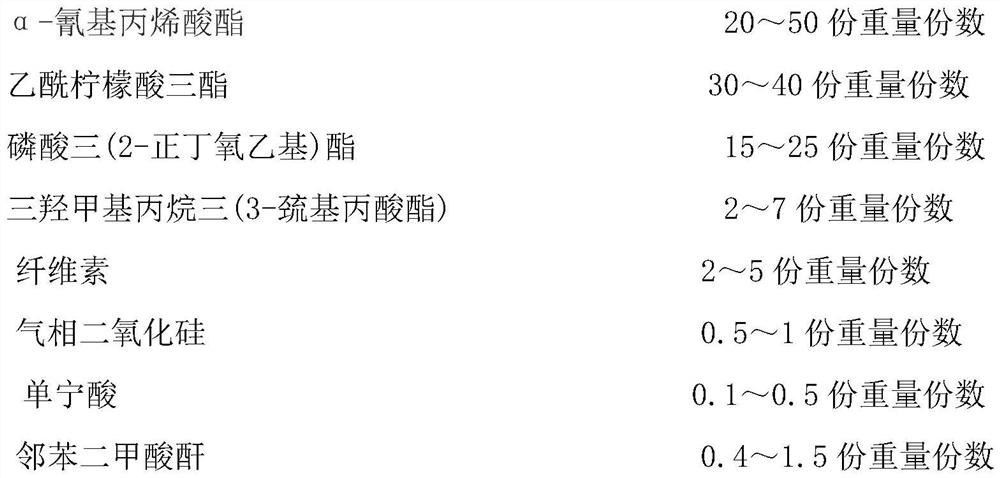

[0032]

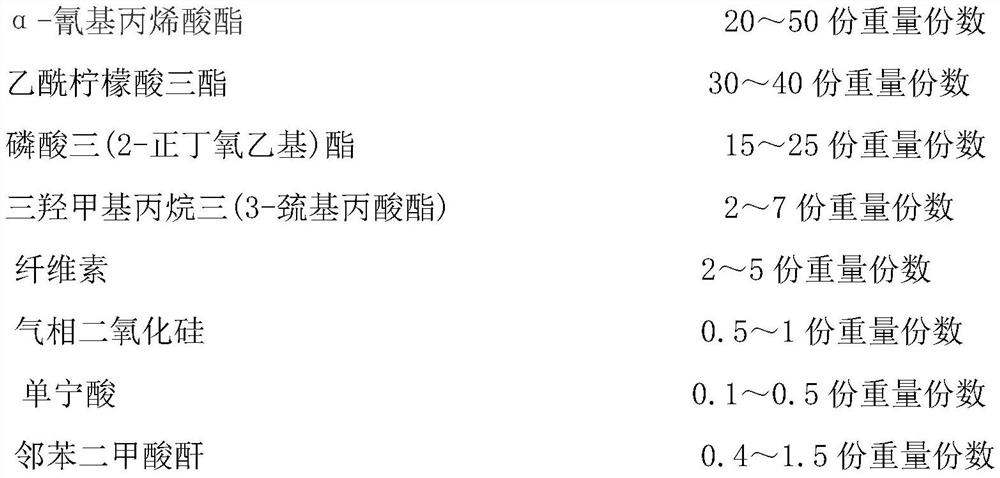

[0033]

[0034] Add the above-mentioned components into a stainless steel reaction kettle in sequence according to the amount, heat at 65° C., and stir evenly under nitrogen protection to obtain the material for optical element processing. Set up 5 groups according to embodiment, its performance is shown in Table 2:

[0035] Table 2.

[0036] serial number Tensile shear strength (MPa) Degumming time (hours) PV value (λ) 1 10.5 4.6 0.06 2 10.2 5.3 0.07 3 10.5 6.2 0.06 4 11.2 5.2 0.04 5 10.8 6.0 0.04

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com