Powdered starch resin aquatic feed adhesive and production method thereof

A technology of starch resin and aquatic feed, applied in the direction of starch-derived adhesives, adhesive types, etc., can solve the problems of high price, non-conformity, water environmental pollution, etc., to reduce production costs, ensure water resistance time, and ensure The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

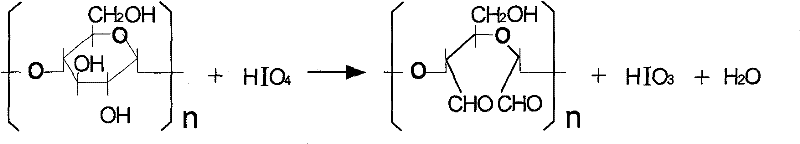

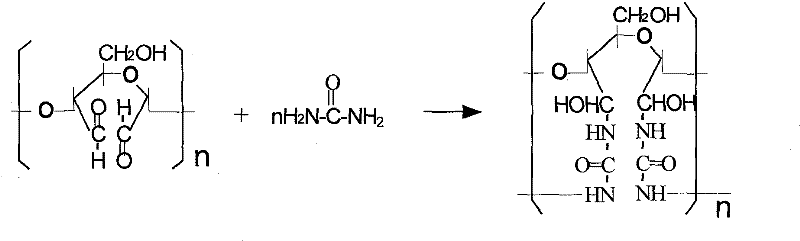

[0020] Embodiment 1, the production method of powder starch resin aquatic feed binder, its process step is: by weight ratio, get 6 parts of starch, add 18 parts of water, stir and become starch emulsion; Get 1 part of sodium periodate in addition, add Concentrated sulfuric acid to adjust the pH value to 1-1.5; then add the prepared sodium periodate solution into the above-mentioned starch emulsion, heat for 1.5 hours, and control the temperature at 35-40°C; after the reaction, wash with distilled water 4 times, and filter to obtain bis Aldehydehyde starch has a dialdehyde content of 12.3% after determination; add 15 parts of water to the dialdehyde starch obtained by the above filtration, stir evenly, add sodium hydroxide to adjust the pH value to 8.5-9, add 0.06 parts of urotropine That is, hexamethylenetetramine is used as a catalyst, heated to 95-98°C, firstly add 0.7 parts of urea, and then add 0.3 parts of urea after reacting for 30 minutes. hour, and then adjust the pH v...

Embodiment 2

[0022] Embodiment 2, the production method of powder starch resin aquatic feed adhesive, its process step is: by weight ratio, get 6 parts of starch, add 18 parts of water, stir to form starch emulsion; Get 2 parts of sodium periodate in addition, add Adjust the pH value to 1-1.5 with concentrated sulfuric acid; then add the prepared sodium periodate solution into the above-mentioned starch emulsion, heat for 2 hours, and control the temperature at 35-40°C; wash with distilled water for 4 times after the reaction, and filter to obtain bis Aldehyde starch, its dialdehyde content is 23.8% after determination; add 15 parts of water to the dialdehyde starch obtained by the above filtration, stir evenly, add sodium hydroxide to adjust the pH value to 8.5-9, add 0.06 part of urotropine As a catalyst, heat to 95-98°C, add 0.7 parts of urea first, then add 0.3 parts of urea after reacting for 30 minutes, adjust the pH value to 4-5 with formic acid after reacting for 1 hour, condense fo...

Embodiment 3

[0024] Embodiment 3, the production method of powder starch resin aquatic feed adhesive, its process step is: by weight ratio, get 6 parts of starch, add 18 parts of water, stir and become starch emulsion; Get 2.5 parts of sodium periodate in addition, add Adjust the pH value to 1-1.5 with concentrated sulfuric acid; then add the prepared sodium periodate solution into the above-mentioned starch emulsion, heat for 2 hours, and control the temperature at 35-40°C; wash with distilled water for 4 times after the reaction, and filter to obtain bis Aldehyde starch; its dialdehyde content was determined to be 29.8%; add 15 parts of water to the dialdehyde starch obtained by the above filtration, stir evenly, add sodium hydroxide to adjust the pH value to 8.5-9, add 0.06 parts of urotropine As a catalyst, heat to 95-98°C, add 0.7 parts of urea first, then add 0.3 parts of urea after reacting for 30 minutes, adjust the pH value to 4-5 with formic acid after reacting for 1 hour, condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com