Double-silver low-emissivity coated glass and preparation method thereof

A low-emissivity coating and glass technology, applied in the direction of coating, etc., can solve the problems of affecting glass light transmittance, poor mechanical adhesion, and affecting product quality, so as to increase anti-infrared radiation performance, increase toughness, and improve anti-radiation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

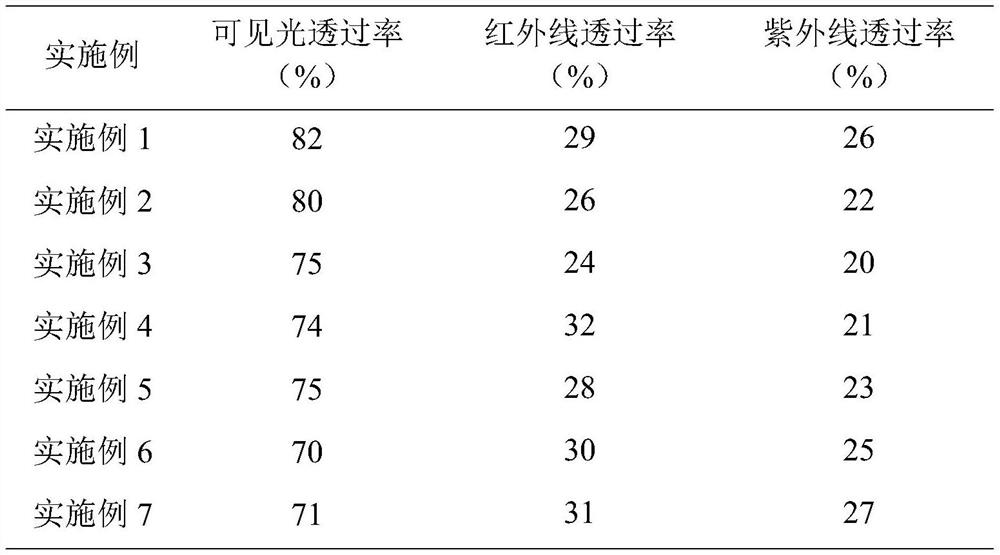

Examples

Embodiment 1

[0042] S1: Glass substrate pretreatment: Polish one side of the glass substrate, clean it with deionized water and isopropanol respectively, dry it with high-purity nitrogen, and treat it with UV ozone for 20 minutes, and set it aside;

[0043] S2: SnOx layer: SnOx is used as the target, medium frequency power supply, sputtering pressure is 4×10 -3 mbar, deposited on the polished surface of a glass substrate under argon to form a SnOx layer with a thickness of 5 nm;

[0044] S3: Conductive adhesive layer: ultrasonically disperse the weighed poly-3,4-ethyldioxythiophene and sodium polystyrene sulfonate in deionized water for 15 minutes, and filter with a 0.45 μm syringe filter head, Form 1wt% dispersion liquid, the gained dispersion liquid adds acetone solvent and mixes to form mixed solution; Use spin coater, setting speed is 1000rmp, spray gun pressure is 0.24MPa, and spraying time is 15 seconds, mixed solution is sprayed on the SnOx layer of glass substrate, Place in a vacu...

Embodiment 2

[0055] S1: Glass substrate pretreatment: Polish one side of the glass substrate, clean it with deionized water and isopropanol respectively, dry it with high-purity nitrogen, and treat it with UV ozone for 45 minutes, and set aside;

[0056] S2: SiNx layer: SnOx is used as the target, medium frequency power supply, sputtering pressure is 4×10 -3 mbar, deposited on the polished surface of a glass substrate under argon to form a SiNx layer with a thickness of 20 nm;

[0057] S3: Conductive adhesive layer: ultrasonically disperse the weighed poly-3,4-ethyldioxythiophene and sodium polystyrene sulfonate in deionized water for 15 minutes, and filter with a 0.45 μm syringe filter head, Form 1.3wt% dispersion liquid, the gained dispersion liquid adds acetone solvent and mixes to form mixed solution; Use spin coater, setting speed is 1200rmp, spray gun pressure is 0.24MPa, and spraying time is 15 seconds, mixed solution is sprayed above the SnOx layer of glass substrate , placed in a...

Embodiment 3

[0068]S1: Glass substrate pretreatment: Polish one side of the glass substrate, clean it with deionized water and isopropanol respectively, dry it with high-purity nitrogen, and treat it with UV ozone for 30 minutes, and set it aside;

[0069] S2: SnOx layer: SnOx is used as the target, medium frequency power supply, sputtering pressure is 4×10 -3 mbar, deposited on the polished surface of a glass substrate under argon to form a SnOx layer with a thickness of 12 nm;

[0070] S3: Conductive adhesive layer: ultrasonically disperse the weighed poly-3,4-ethyldioxythiophene and sodium polystyrene sulfonate in deionized water for 15 minutes, and filter with a 0.45 μm syringe filter head, Form 1.15wt% dispersion liquid, the gained dispersion liquid adds acetone solvent and mixes and forms mixed solution; Use spin coater, setting speed is 1100rmp, and spray gun pressure is 0.24MPa, and spraying time is 15 seconds, and mixed solution is sprayed above the SnOx layer of glass substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com