Functional gradient composite structure wear-resistant transparent super-hydrophobic coating and preparation method thereof

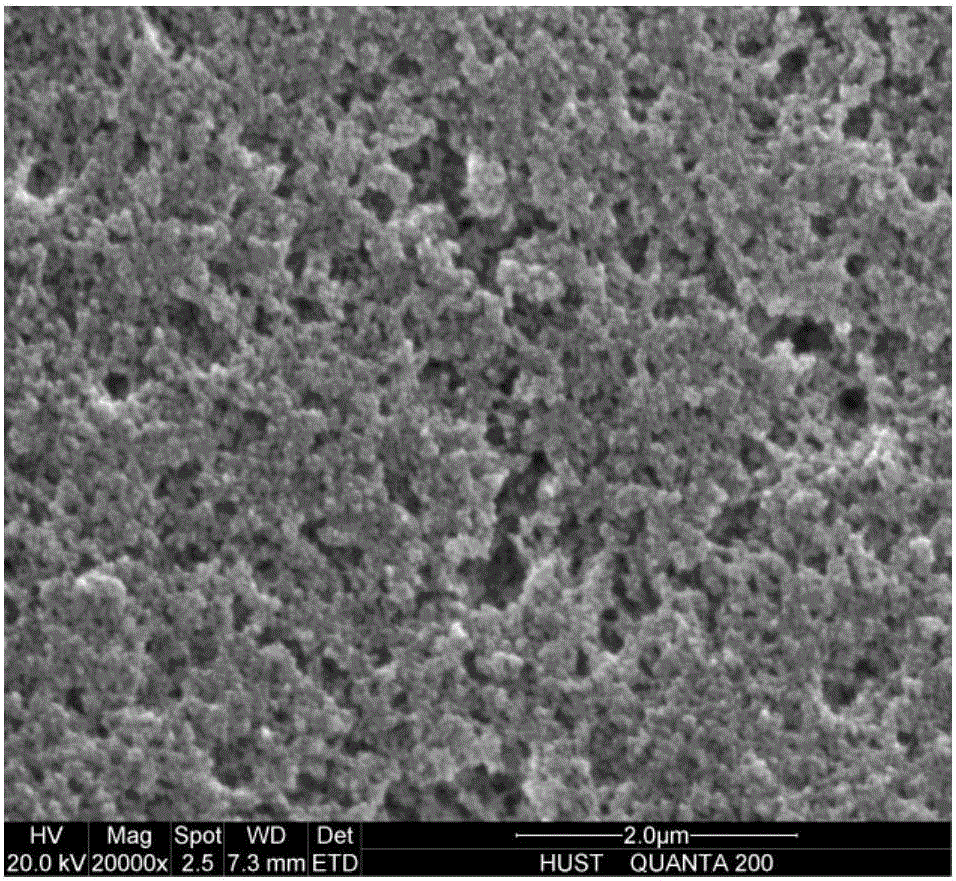

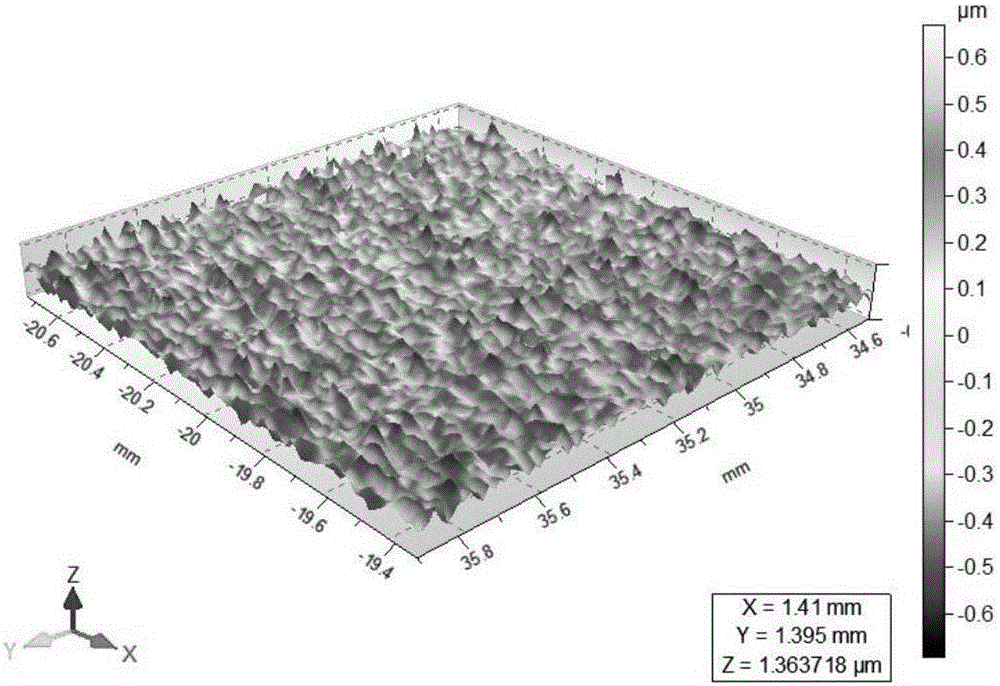

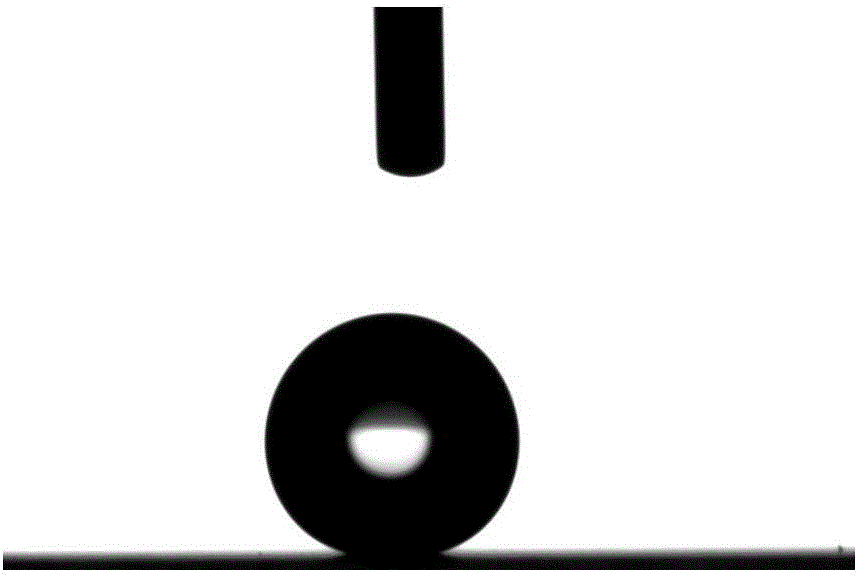

A super-hydrophobic coating and composite structure technology, applied in coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc., can solve the problem of poor aging resistance, low mechanical strength, and insufficient transparency of super-hydrophobic coatings. problem, to achieve the effect of good mechanical properties, good hydrophobic properties, and excellent self-cleaning properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A. Preparation of modified enhanced bonding layer solution:

[0054] Take 10ml of polyurethane solution with a volume concentration of 40% in a beaker, add 60ml of acetone solution with a volume concentration of 99%, ultrasonically disperse for 1 hour, and stir for 2 hours until it is completely dissolved to obtain a modified and reinforced adhesive layer solution.

[0055] B. Preparation of polyurethane and silica mixed transition layer solution:

[0056] The modified enhanced bonding layer solution is mixed with the micro-nano superhydrophobic layer matrix solution according to the volume ratio of 1:2, and after stirring, a transition layer solution mixed with polyurethane and silicon dioxide is obtained.

[0057] C. Preparation of micro-nano superhydrophobic layer matrix solution:

[0058] (1) Dissolve 2ml of a 99% volume concentration methyltrimethoxysilane solution in 19.48ml of a volume concentration of 99% methanol, fully stir it at room temperature to dissolve ...

Embodiment 2

[0070] A. Preparation of modified enhanced bonding layer solution:

[0071] Take 10ml of polyurethane solution with a volume concentration of 40% in a beaker, add 60ml of acetone solution with a volume concentration of 99%, ultrasonically disperse for 1 hour, and stir for 2 hours until it is completely dissolved to obtain a modified and reinforced adhesive layer solution.

[0072] B. Preparation of polyurethane and silica mixed transition layer solution:

[0073] The modified enhanced bonding layer solution is mixed with the micro-nano superhydrophobic layer matrix solution according to the volume ratio of 1:2, and after stirring, a transition layer solution mixed with polyurethane and silicon dioxide is obtained.

[0074] C. Preparation of micro-nano superhydrophobic layer matrix solution:

[0075] (1) Dissolve 2ml of a 99% volume concentration methyltrimethoxysilane solution in 19.48ml of a volume concentration of 99% methanol, fully stir it at room temperature to dissolve ...

Embodiment 3

[0087] A. Preparation of modified enhanced bonding layer solution:

[0088] Take 10ml of polyurethane solution with a volume concentration of 40% in a beaker, add 60ml of acetone solution with a volume concentration of 99%, ultrasonically disperse for 1 hour, and stir for 2 hours until it is completely dissolved to obtain a modified and reinforced adhesive layer solution.

[0089] B. Preparation of polyurethane and silica mixed transition layer solution:

[0090] The modified enhanced bonding layer solution is mixed with the micro-nano superhydrophobic layer matrix solution according to the volume ratio of 1:2, and after stirring, a transition layer solution mixed with polyurethane and silicon dioxide is obtained.

[0091] C. Preparation of micro-nano superhydrophobic layer matrix solution:

[0092] (1) Dissolve 2ml of a 99% volume concentration methyltrimethoxysilane solution in 19.48ml of a volume concentration of 99% methanol, fully stir it at room temperature to dissolve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com