Polybutylene terephthalate resin composition

A technology of polybutylene terephthalate and resin composition, applied in the field of polybutylene terephthalate resin composition, can solve problems such as surface appearance deterioration, and achieve excellent alkali resistance, high resistance The effect of thermal shock resistance and high alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 4 and comparative example 1 to 3

[0184]

[0185] The components described in Table 1 except glass fibers were blended in the proportions (parts by mass in all cases) given in Table 2 below and used a curved 30 mm twin-screw extruder (TEX30α twin-screw extruder , from Japan Steel Works, Ltd.), and glass fibers supplied from a side feeder, were melt-kneaded at a barrel temperature of 270°C. After extrusion in the form of strands, pelletization was performed using a strand cutter to obtain pellets of the polybutylene terephthalate resin composition.

[0186]

[0187] Various physical properties and performances in Examples and Comparative Examples were measured and evaluated using the following methods.

[0188] (a) Charpy impact strength (unit: kJ / m 2 ):

[0189] The obtained pellets were dried at 120° C. for 6 hours, and then made using the “NEX80-9E” injection molding machine from Nissei Plastic Industrial Co., Ltd. and using the conditions of a barrel temperature of 250° C. and a mold temperature of 80...

Embodiment 21 to 24 and comparative example 21

[0216]

[0217] The components described in Table 1 except glass fibers were blended in the ratios given in Table 3 below (all substances are parts by mass) and a curved 30 mm twin-screw extruder (TEX30α twin-screw extruder, Japan SteelWorks, Ltd.), and glass fibers supplied from a side feeder, were melt-kneaded at a barrel temperature of 270°C. After extrusion in the form of strands, pelletization was performed using a strand cutter to obtain pellets of the polybutylene terephthalate resin composition.

[0218]

[0219] The measurement and evaluation were performed as described above while measuring the laser welding strength using the following method.

[0220] (e) Laser welding strength (unit: N)

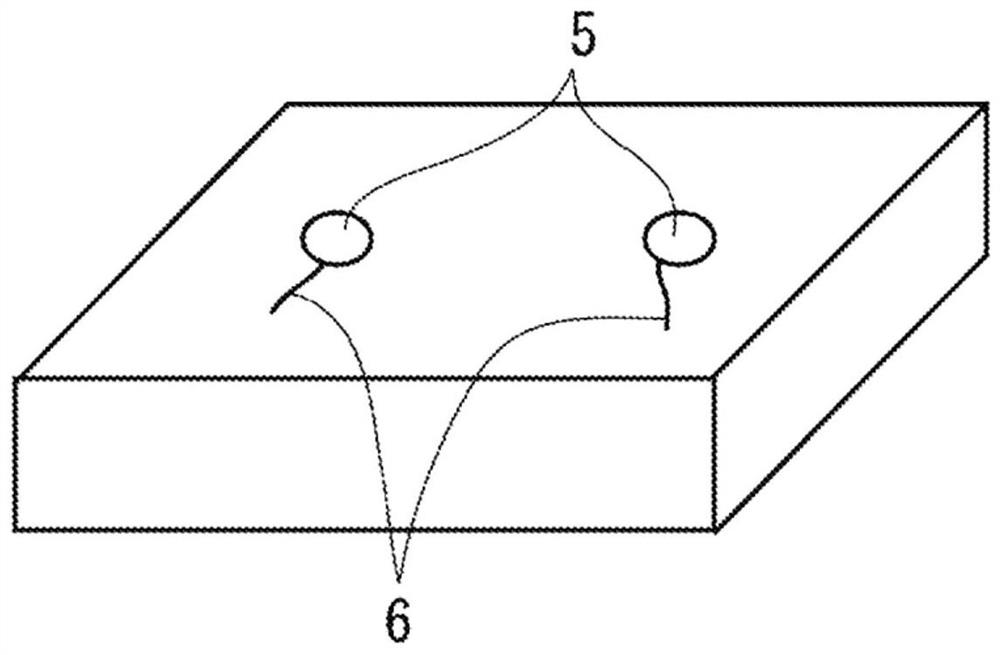

[0221] In order to measure the laser welding strength, make as Figure 4 A cylindrical absorbing side member 7 and a disk-like transmitting side member 8 are shown; these are laminated on each other, and laser welded to obtain a laser welded body; and the weld strength ther...

Embodiment 21 to 23 and comparative example 21 and 22

[0240]

[0241] The components described in Table 1 except glass fibers were blended in the ratios given in Table 4 below (all substances are parts by mass) and a curved 30 mm twin-screw extruder (TEX30α twin-screw extruder , from Japan Steel Works, Ltd.), and glass fibers supplied from a side feeder, were melt-kneaded at a barrel temperature of 270°C. After extrusion in the form of strands, pelletization was performed using a strand cutter to obtain pellets of the polybutylene terephthalate resin composition.

[0242]

[0243] The measurement and evaluation were performed as described above while measuring the bonding strength using the following method.

[0244] (f) Joint strength (unit: N)

[0245] Production of two-color formed test pieces for measuring joint strength:

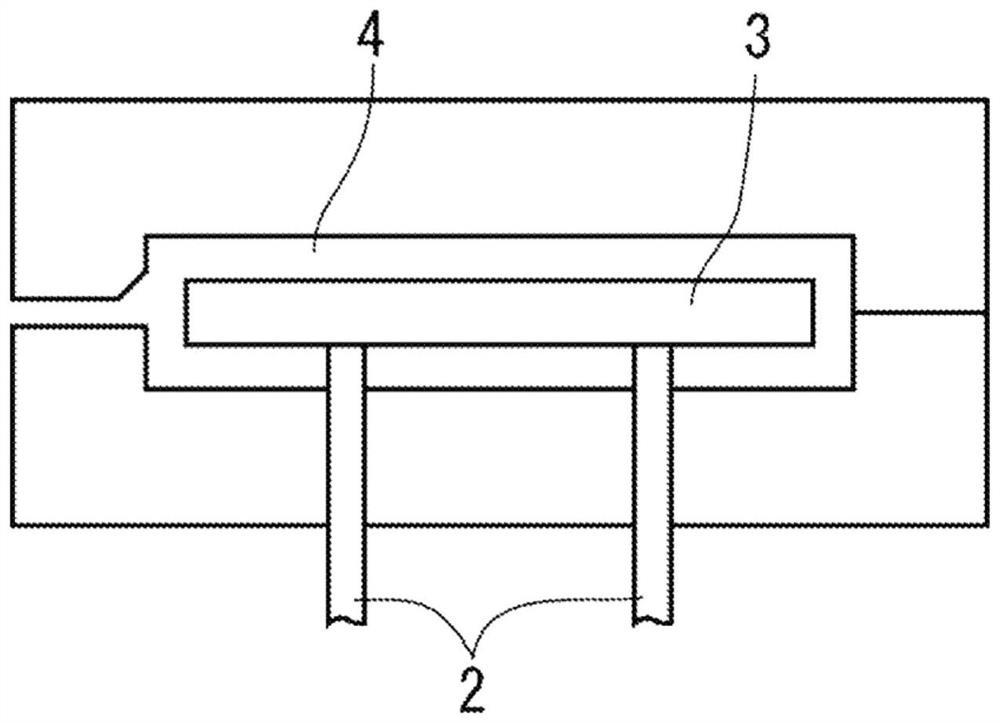

[0246]ISO-1A contact type two-color molding test pieces were molded using an injection molding machine from Japan Steel Works, Ltd., namely, "J180AD-2M (clamping force 180t, screw diameter barrel A=4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com