A rare-earth electro-induced deep blue light device

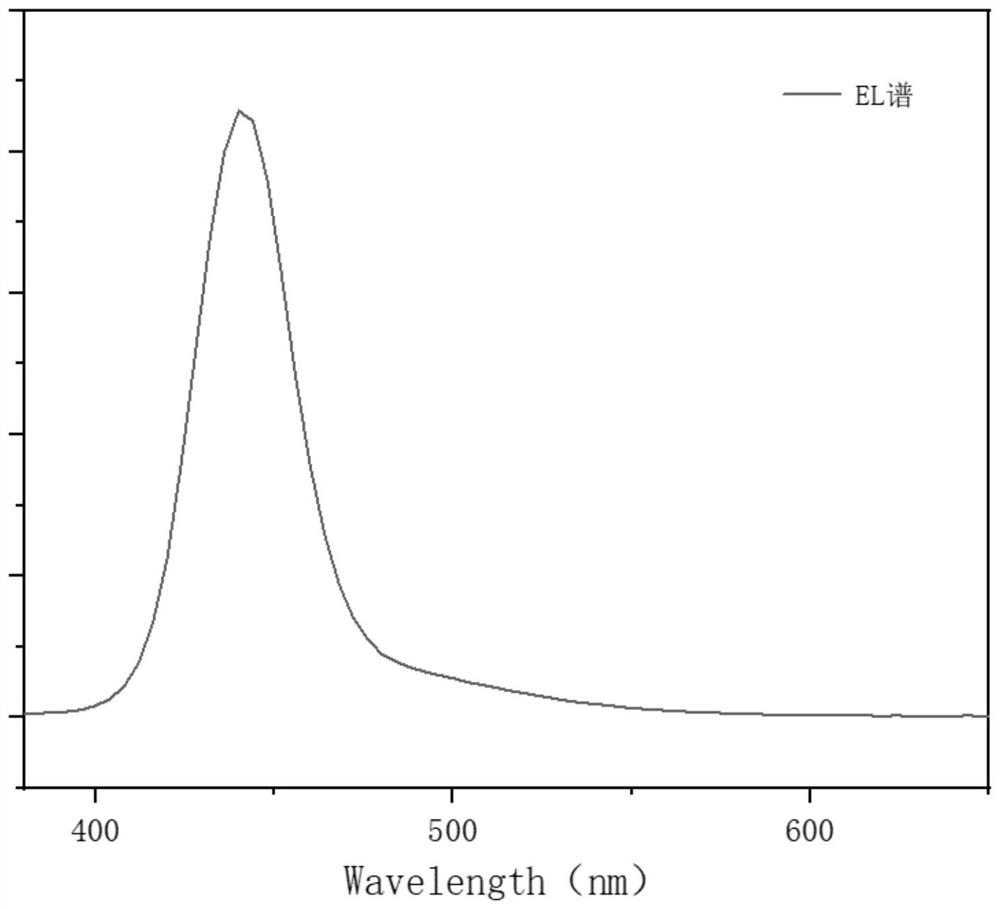

An optical device, dark blue technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of easy aging, poor OLED stability, blue light color distortion, etc., and achieve the effect of not easy aging, good stability, and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

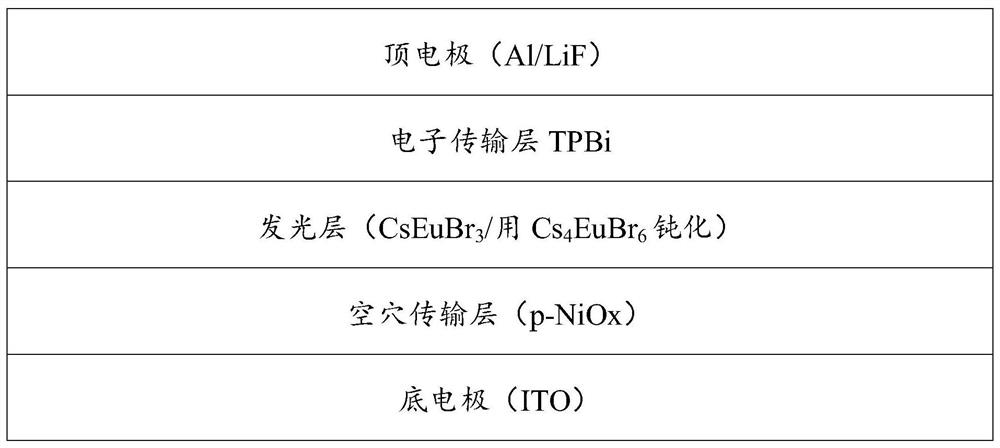

[0038] In this embodiment, the light-emitting layer material is passivated CsEuBr 3 Taking an electroluminescent blue light device as an example, its specific preparation method includes the following steps:

[0039] a) Use detergent, deionized water, acetone and absolute ethanol to ultrasonically clean the substrate ITO in sequence, for half an hour each time; where, ITO uses a substrate that has been etched two times, and its light-emitting area is about 2mm*2mm;

[0040] b) Using magnetron sputtering method on ITO, sputtering Li-doped p-type NiO with a thickness of about 40nm, wherein the doping concentration is 10 16 -10 17 cm -3 ;

[0041] c) Put the substrate coated with NiO film into the evaporation glove box, and pump the vacuum to 4*10 -5 Below Pa, the substrate is heated to 200°C, and EuBr is evaporated at a speed of 0.11nm / s by co-evaporation 2 , CsBr was evaporated at a speed of 0.14nm / s, with a total thickness of 100nm. In the dual-source co-evaporation proc...

Embodiment 2

[0051] In this embodiment, the light-emitting layer material is passivated CsEuBr 3 Taking an electroluminescent blue light device as an example, its specific preparation method includes the following steps:

[0052] a) Use detergent, deionized water, acetone and absolute ethanol to ultrasonically clean the substrate ITO in sequence, for half an hour each time; where, ITO uses a substrate that has been etched two times, and its light-emitting area is about 2mm*2mm;

[0053] b) Using magnetron sputtering method on ITO, sputtering Li-doped p-type NiO with a thickness of about 40nm, wherein the doping concentration is 10 16 -10 17 cm -3 ;

[0054] c) Put the substrate coated with NiO film into the evaporation glove box, and pump the vacuum to 4*10 -5 Below Pa, the substrate is heated to 200°C, and EuBr is evaporated at a speed of 0.12nm / s by co-evaporation 2 , CsBr was vapor-deposited at a speed of 0.18nm / s, and a total thickness of 100nm was vapor-deposited.

[0055] d) Ta...

Embodiment 3

[0058] In this embodiment, the light-emitting layer material is passivated CsEuBr 3 Taking an electroluminescent blue light device as an example, its specific preparation method includes the following steps:

[0059] a) Use detergent, deionized water, acetone and absolute ethanol to ultrasonically clean the substrate ITO in sequence, for half an hour each time; where, ITO uses a substrate that has been etched two times, and its light-emitting area is about 2mm*2mm;

[0060] b) Using magnetron sputtering method on ITO, sputtering Li-doped p-type NiO with a thickness of about 40nm, wherein the doping concentration is 10 16 -10 17 cm -3 ;

[0061] c) Put the substrate coated with NiO film into the evaporation glove box, and pump the vacuum to 4*10 -5 Below Pa, the substrate is heated to 200°C, and EuBr is evaporated at a speed of 0.115nm / s by co-evaporation 2 , CsBr was evaporated at a speed of 0.16nm / s, and a total thickness of 100nm was evaporated.

[0062] d) Take the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| hole mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com