A kind of high carbon medium chromium wear-resistant cast iron and preparation method thereof

A wear-resistant cast iron, high-carbon technology, applied in the field of wear-resistant cast iron, can solve the problems of further improvement of hardness, complicated heat treatment process, long heat treatment time, etc., and achieves the effects of low production cost, simple preparation method and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

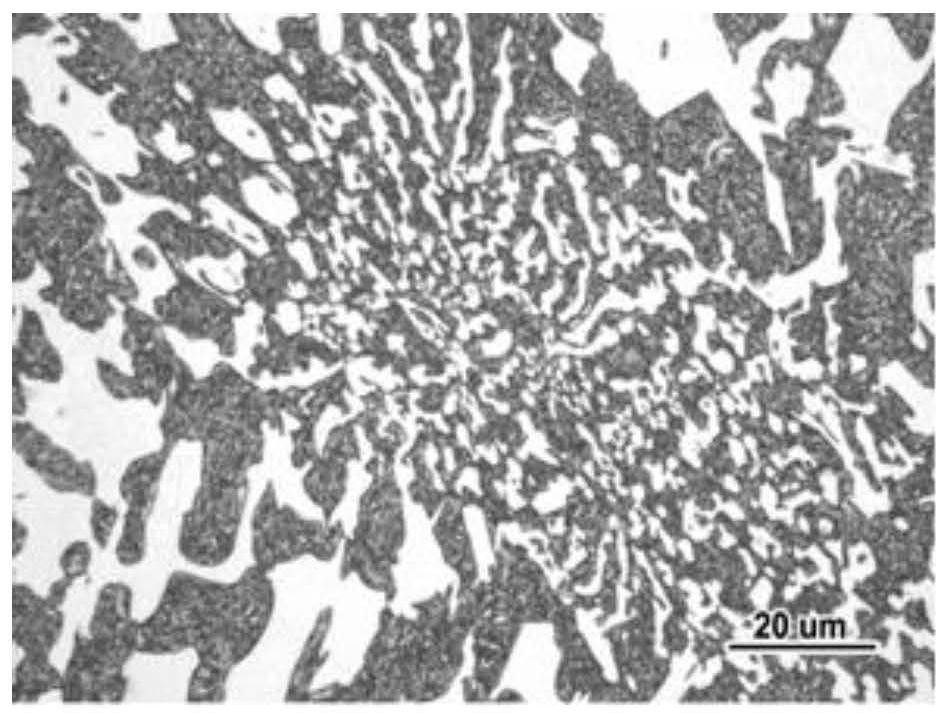

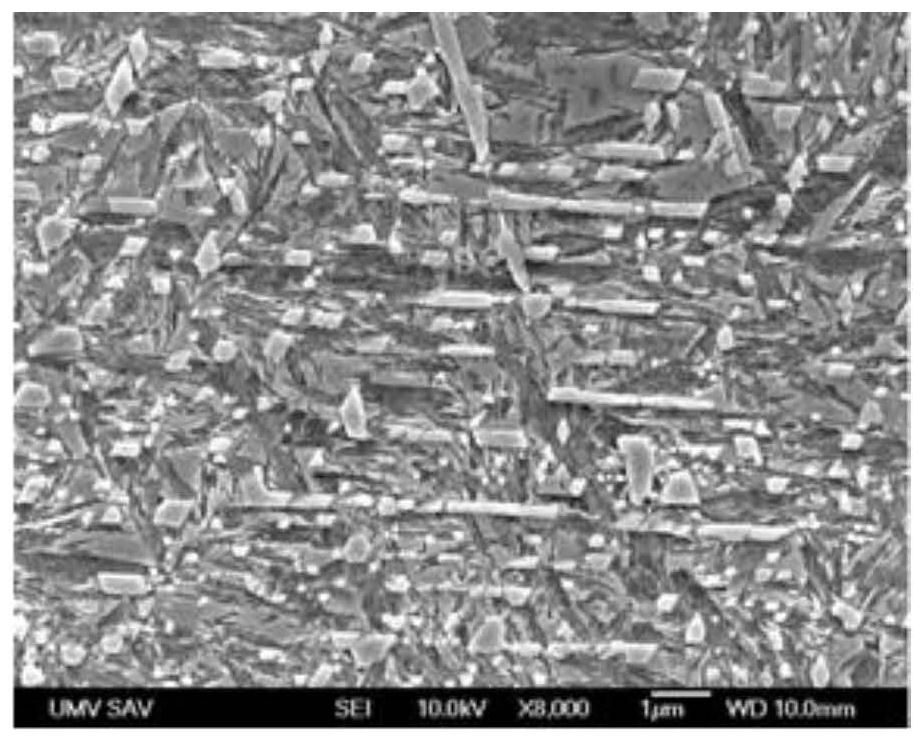

[0029] A high-carbon medium-chromium wear-resistant cast iron and a preparation method thereof. The chemical composition and content of the high-carbon medium-chromium wear-resistant cast iron are: C is 3.63wt%, Cr is 12.16wt%, Si is 0.51wt%, Mn is 0.63wt%, Mo is 1.72wt%, and B is 0.32wt%. wt%, P≤0.03wt%, S≤0.03wt%, the balance is Fe and unavoidable impurities; wherein: Cr / C=3.350, B / Mo=0.186.

[0030] According to the chemical composition and its content, it is formulated, smelted, poured, air-cooled to room temperature, and ground; then heated to 850°C, kept for 3 hours, quenched into oil, and cooled to room temperature to produce high-carbon medium-chromium wear-resistant cast iron.

[0031] The high-carbon medium-chromium wear-resistant cast iron prepared by the invention is tested: the carbide content is 40vol%, the retained austenite is 10.8vol%; the rest is martensite; the high-carbon medium-chromium wear-resistant cast iron has a hardness of 70.3HRC.

Embodiment 2

[0033] A high-carbon medium-chromium wear-resistant cast iron and a preparation method thereof. The chemical composition and content of the high carbon medium chromium wear-resistant cast iron are: C is 3.74wt%, Cr is 14.90wt%, Si is 0.61wt%, Mn is 0.69wt%, Mo is 1.85wt%, B is 0.38 wt%, P≤0.03wt%, S≤0.03wt%, the balance is Fe and unavoidable impurities; wherein: Cr / C=3.984, B / Mo=0.205.

[0034] According to the chemical composition and its content, it is formulated, smelted, poured, air-cooled to room temperature, and ground; then heated to 950°C, kept for 2 hours, quenched into oil, and cooled to room temperature to produce high-carbon medium-chromium wear-resistant cast iron.

[0035] The high-carbon medium-chromium wear-resistant cast iron prepared by the invention is tested: the carbide content is 45vol%, the retained austenite is 8vol%, and the rest is martensite; the high-carbon medium-chromium wear-resistant cast iron has a hardness of 71HRC.

Embodiment 3

[0037] A high-carbon medium-chromium wear-resistant cast iron and a preparation method thereof. The chemical composition and content of the high-carbon medium-chromium wear-resistant cast iron are: C is 3.81wt%, Cr is 14.14wt%, Si is 0.78wt%, Mn is 0.75wt%, Mo is 1.98wt%, and B is 0.31wt%. wt%, P≤0.03wt%, S≤0.03wt%, the balance is Fe and unavoidable impurities; wherein: Cr / C=3.711, B / Mo=0.156.

[0038] According to the chemical composition and its content, it is formulated, smelted, poured, air-cooled to room temperature, and ground; then heated to 1000°C, kept for 1 hour, quenched into oil, and cooled to room temperature to produce high-carbon medium-chromium wear-resistant cast iron.

[0039] The high-carbon medium-chromium wear-resistant cast iron prepared by the invention is tested: the carbide is 47vol%, the retained austenite is 9.2vol%, and the rest is martensite; the hardness of the high-carbon medium-chromium wear-resistant cast iron is 69.4HRC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com