Carbon fiber surface grafted two-dimensional network structure reinforced polyether-ether-ketone composite material and preparation method thereof

A technology of polyether ether ketone and network structure, applied in the field of carbon fiber surface grafted two-dimensional network structure reinforced polyether ether ketone composite material and its preparation, can solve the problem of destroying CF strength, limiting the degree of interface modification of composite materials, and the interaction Weakness and other problems, to achieve the effect of increasing mechanical interlocking effect, improving mechanical strength and toughness, and increasing interface bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of a carbon fiber surface-grafted two-dimensional network structure reinforced polyetheretherketone composite material, comprising the following steps:

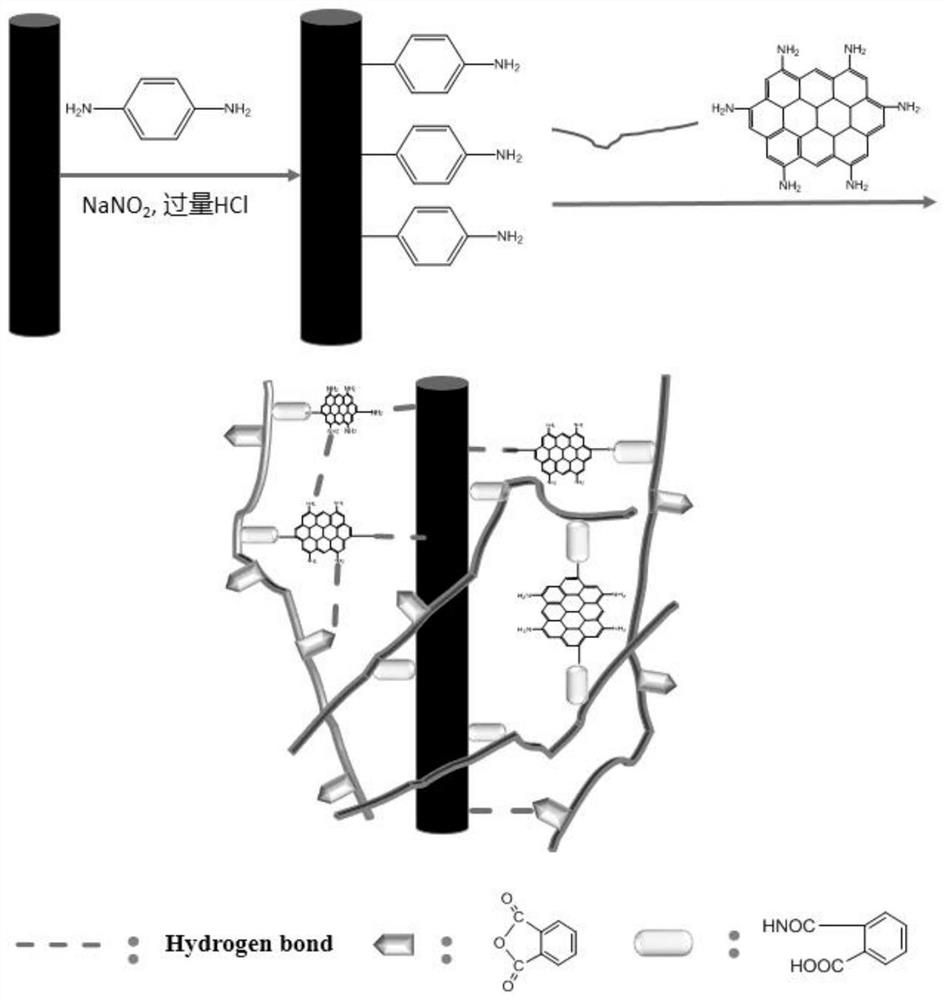

[0030] Mixing carbon fiber, p-phenylenediamine, nitrite and concentrated hydrochloric acid to carry out diazotization reaction to obtain aminated carbon fiber;

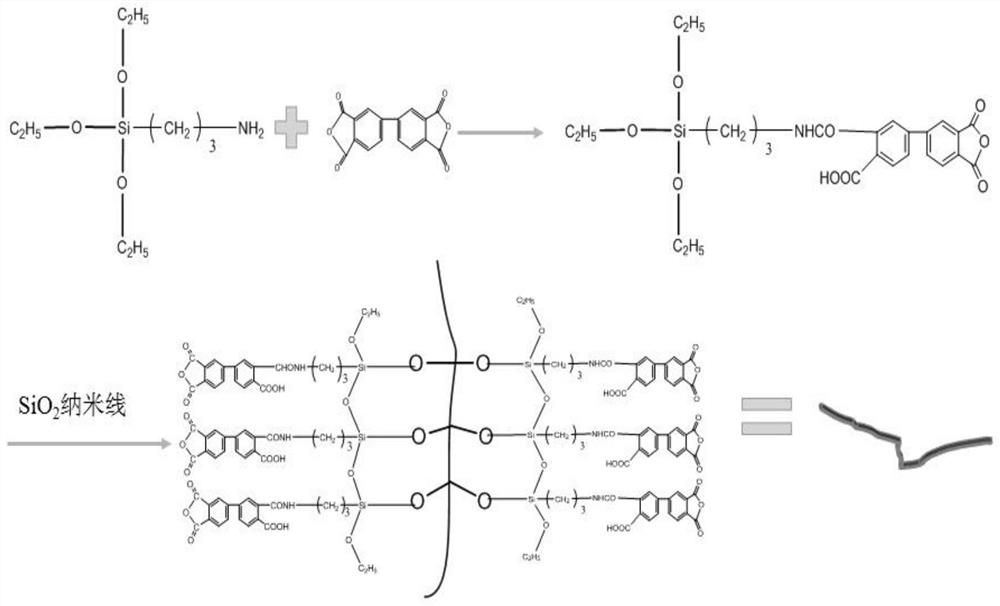

[0031] Mixing the biphenyl dianhydride, the aminosilane coupling agent and the first solvent, and modifying it to obtain a modified silane coupling agent;

[0032] Mixing the dispersion of silica nanowires with the modified silane coupling agent, and performing modification, to obtain modified silica nanowires;

[0033] Mixing the modified silica nanowires, aminated graphene, aminated carbon fibers and a second solvent, and performing grafting to obtain a two-dimensional network structure grafted carbon fiber;

[0034]The two-dimensional network structure-grafted carbon fiber and polyetheretherketone are mixed, and ...

Embodiment 1

[0062] 20g of chopped carbon fiber (SCF) was added to a concentrated hydrochloric acid solution (38% by mass) containing 0.25g of p-phenylenediamine and 0.25g of sodium nitrite, and the pH value was adjusted to 1. After nitriding reaction for 8 hours, use deionized water to wash to neutrality, and vacuum dry to obtain aminated carbon fiber, which is denoted as NH 2 -CF;

[0063] Under nitrogen protection and room temperature, 0.25g of biphenyl dianhydride was dissolved in DMAc solvent. After it was dissolved, 0.25g of KH550 was added dropwise for modification for 5h. After the reaction was completed, the solvent was distilled off under reduced pressure, and anhydrous methanol was used. Washing, after multiple recrystallizations from ethanol, drying to obtain modified KH550 (g-KH550);

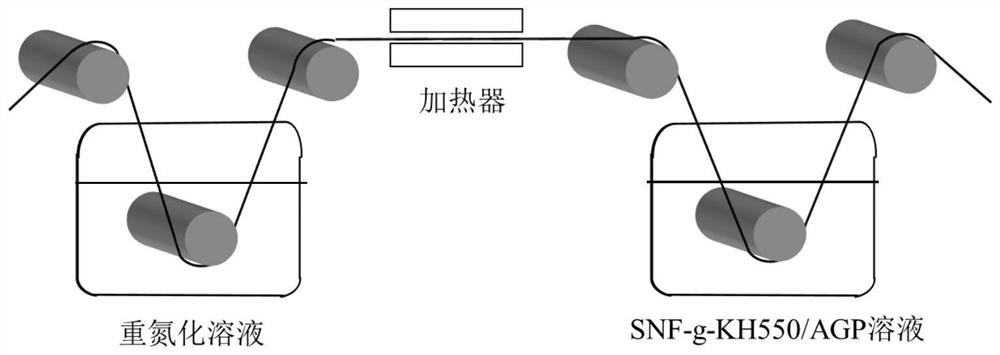

[0064] 0.5g SNF (silicon dioxide nanowires) was ultrasonically dispersed in ethanol for 2h, and the g-KH550 was rapidly added at 60°C for 8h, and the unreacted g-KH550 was removed by washing wi...

Embodiment 2

[0070] 20g of chopped carbon fiber (SCF) was added to a concentrated hydrochloric acid solution (38% by mass) containing 0.30g of p-phenylenediamine and 0.30g of sodium nitrite, and the pH value was adjusted to 1. After nitriding reaction for 8 hours, use deionized water to wash to neutrality, and vacuum dry to obtain aminated carbon fiber, which is denoted as NH 2 -CF;

[0071] Under nitrogen protection and room temperature, 0.30 g of biphenyl dianhydride was dissolved in DMAc solvent. After it was dissolved, 0.30 g of KH550 was added dropwise for modification for 5 hours. After the reaction was completed, the solvent was distilled off under reduced pressure, and anhydrous methanol was used. Washing, after multiple recrystallizations from ethanol, drying to obtain modified KH550 (g-KH550);

[0072] 1 g of SNF was ultrasonically dispersed in ethanol for 2 hours, and the g-KH550 was rapidly added at 60°C for 8 hours. After modification, the unreacted g-KH550 was washed with et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com