Titanium alloy compressor blade welding repair method

A welding repair and compressor technology, applied in the field of welding, can solve the problems of demanding blade forming accuracy and welding quality, deterioration of welding joint performance, and easy oxygen absorption of welding pool, so as to improve welding quality, reduce heat input, increase The effect of cooling intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

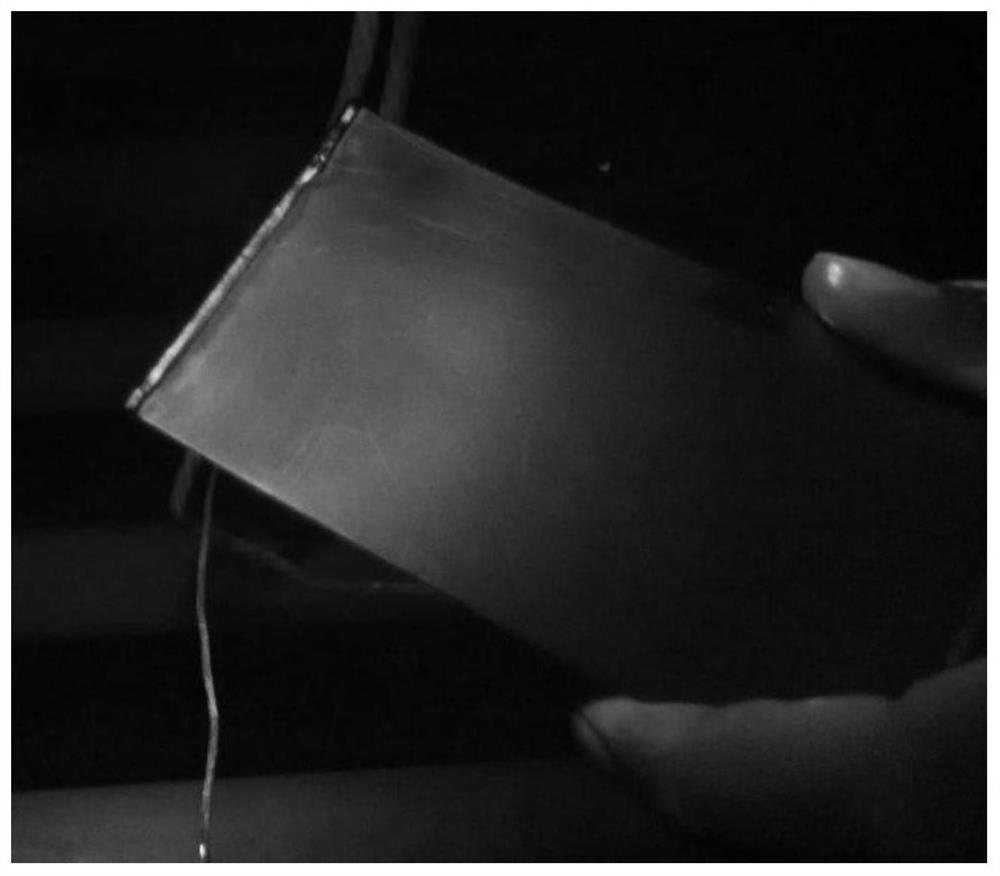

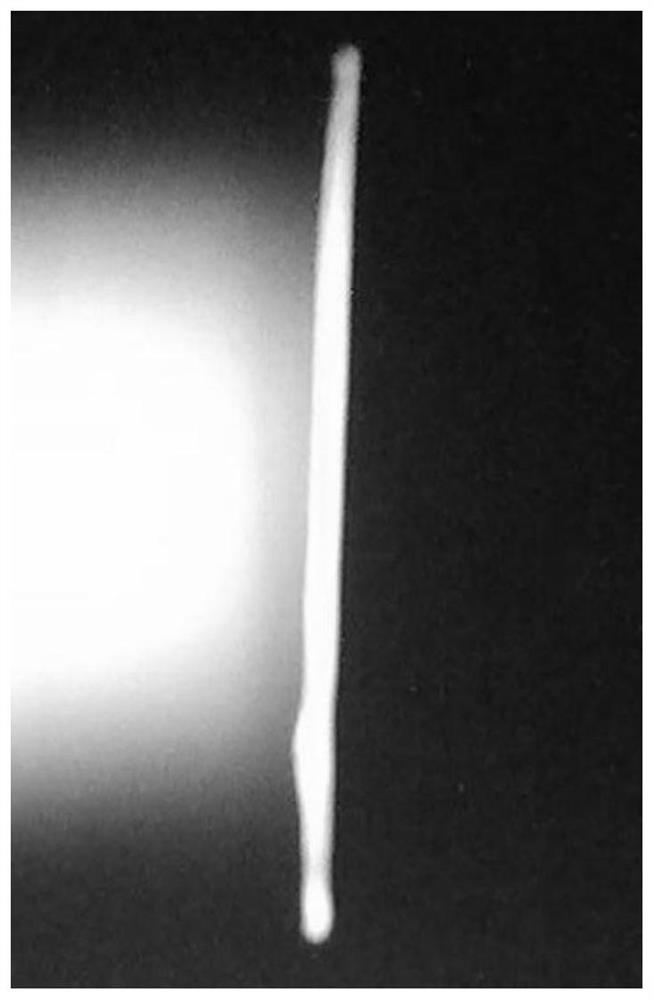

[0027] A titanium alloy compressor blade welding repair method, the method comprises the steps of:

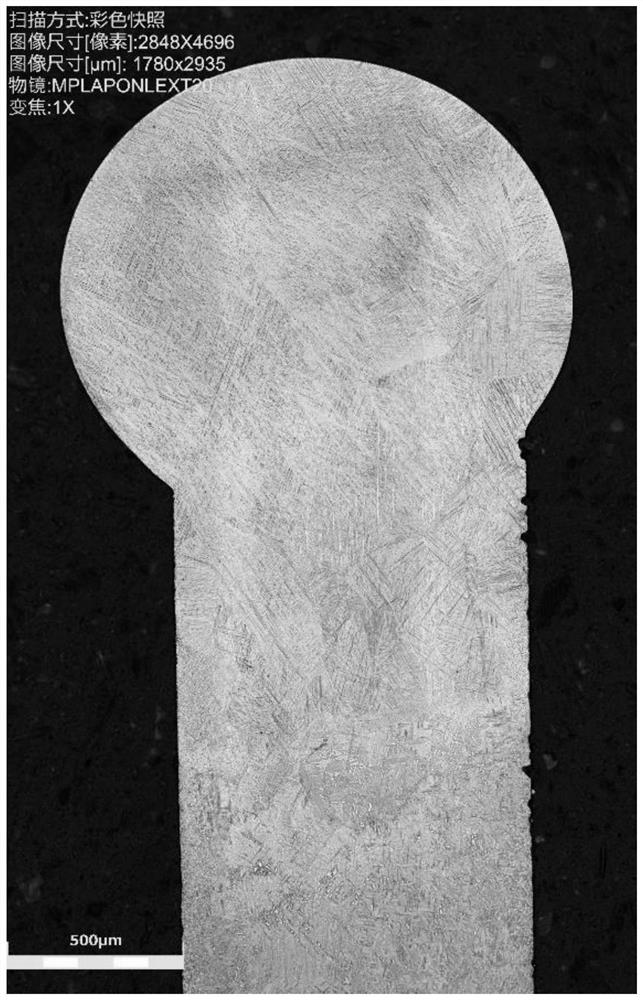

[0028] 1) Machining before welding: cut off the damaged part of the blade, the cutting position is limited to the tip of the blade, the inlet edge of the blade, and the exhaust edge of the blade, and the incision is polished by mechanical grinding, and the edge of the incision is required to be neat and flat. It presents a metallic luster, and the surface roughness is better than Ra0.4.

[0029] 2) Leaf inspection: Use the fluorescent penetrant detection method to inspect the processed leaves. The inspection standard refers to the ASTM E1417 standard to confirm whether the cracks at the damaged parts are completely removed. If there are still...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com