Automatic shape-followed clamping device and clamping method thereof

An automatic clamping and follow-the-shape technology, which is applied in the direction of clamping device, positioning device, clamping, etc., can solve the problem of unsatisfactory use effect of positioning fine-tuning mechanism, and achieve the effect of simple structure, convenient operation and protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

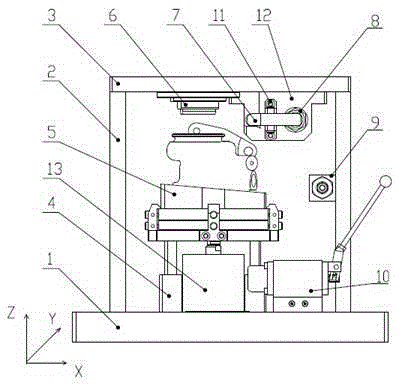

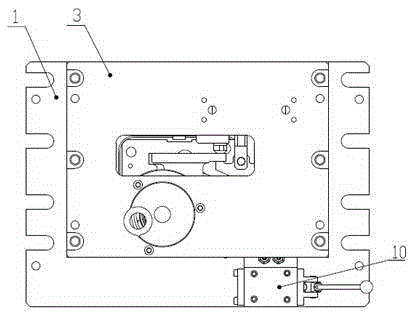

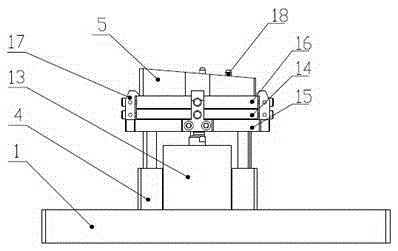

[0032] The invention discloses a conformal automatic clamping device and its clamping method which are suitable for clamping and positioning during the processing of vehicle parts. The first clamping assembly for fine-tuning the position of the piece, the upper part of the first clamping assembly is coaxially provided with the end face inner hole positioning seat 6, and the first clamping assembly or the end face inner hole positioning seat 6 are at least One of them can move axially and cooperate with each other to complete the vertical clamping of the workpiece to be processed.

[0033] The first clamping assembly includes a position fine-tuning mechanism for conformal fine-tuning of the workpiece to be processed. The position fine-tuning mechanism includes an upper plate and a lower plate. Both the bottom end of the upper plate and the top end of the lower plate are provided with Grooves, balls 19 are arranged in the grooves.

[0034] One embodiment of the above technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com