Preparation method of bismuth vanadate doped graphite phase carbon nitride nanosheet photocatalyst

A graphite phase carbon nitride and photocatalyst technology, applied in the field of environmental restoration, can solve the problems of low apparent charge separation efficiency, charge carrier recombination hindering performance, industrial application, and application field limitations, etc., and achieve visible light response capability Enhance and improve photocatalytic performance, beneficial to the effect of light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of bismuth vanadate doped graphite phase carbon nitride nanosheet photocatalyst of the present invention, its steps are:

[0022] Step 1: Add 2~5g of graphite phase carbon nitride into 20mL of 2~8mol / L acetic acid, stir for 30~90min; ultrasonic for 5~30min; obtain solution A;

[0023] Second step: join bismuth chloride and sodium metavanadate with molar ratio 1:1 in the above-mentioned solution A, control graphite phase carbon nitride and bismuth vanadate mass ratio 1:1~4:1; Regulate solution pH as 5-7; heat the mixed solution in an oven at 160-200° C. for 8-20 hours; centrifuge and wash the reaction solution, and dry to obtain bismuth vanadate-doped graphite-phase carbon nitride nanosheets.

[0024] The environmental remediation material of the present invention is used for organic wastewater treatment and CO 2 The recovery method includes the following steps:

[0025] (1) Photocatalytic environmental restoration materials are added to organic ...

Embodiment 1

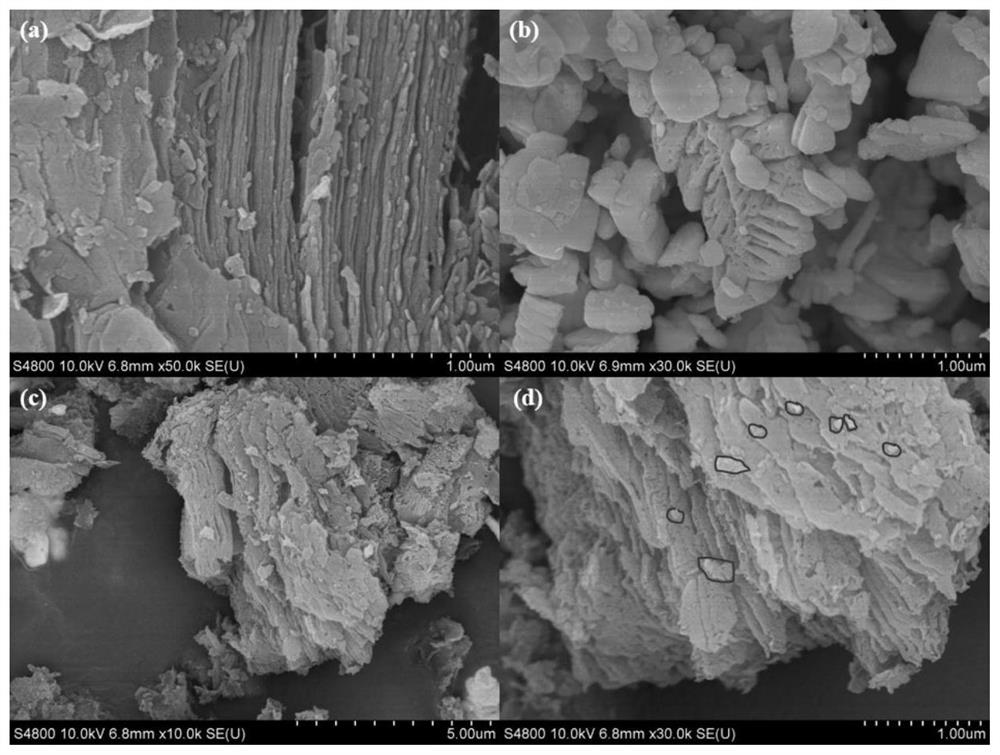

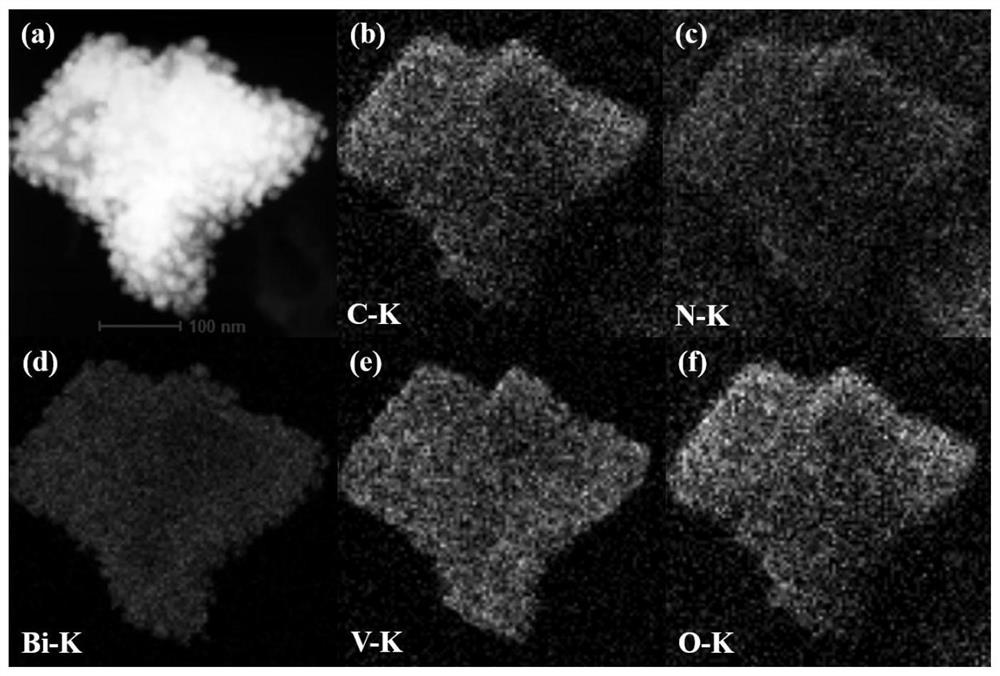

[0029] Add 2g of graphite phase carbon nitride to 20mL 4mol / L acetic acid, stir for 90min; sonicate for 30min to obtain solution A; add bismuth chloride and sodium metavanadate with a molar ratio of 1:1 into solution A to control the graphite phase The mass ratio of carbon nitride and bismuth vanadate is 4:1; the pH of the solution is adjusted to 5 with 2mol / L sodium hydroxide; the mixed solution is transferred to a polytetrafluoroethylene reactor and heated in an oven at 190°C for 12h; Centrifuge at a speed of 1 min for 5 min, and repeat 3 times; wash the precipitate 3 times with deionized water and absolute ethanol, and dry overnight at 60°C to obtain bismuth vanadate-doped graphite-phase carbon nitride nanosheets. Its scanning electron microscope picture is as figure 1 As shown, UTCN has a typical hierarchical structure, BiVO 4 Stacked block structure, UTCN / BiVO 4 Composites retain UTCN and BiVO 4 The structure of BiVO 4 Firmly anchored on UTCN. Its high magnification ...

Embodiment 2

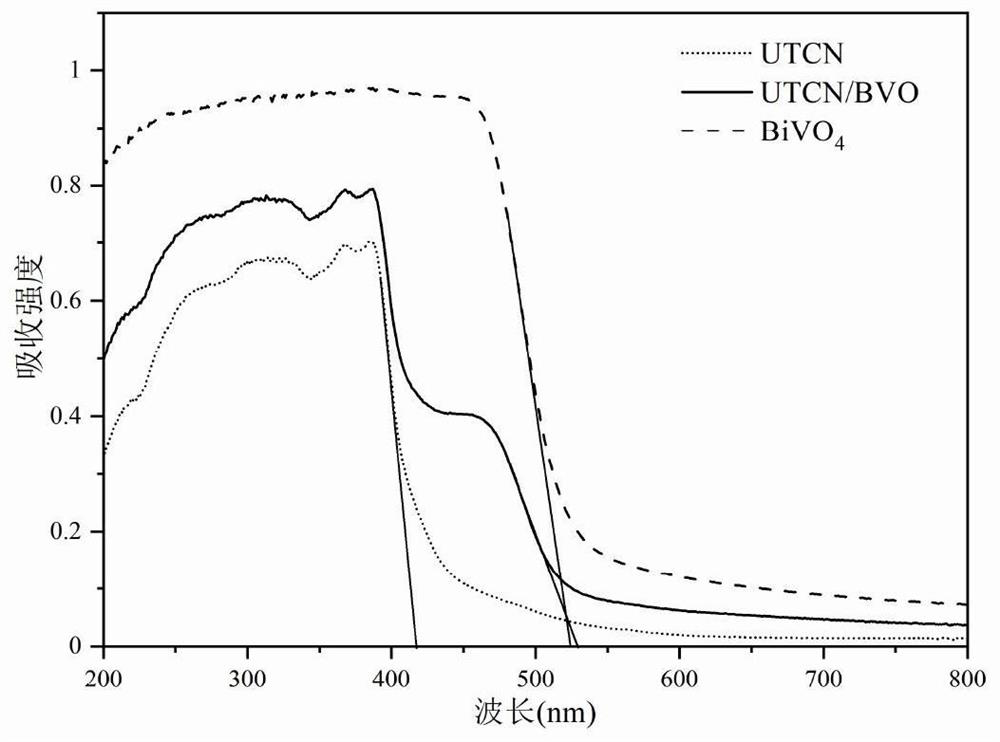

[0031] Add 2g of graphite phase carbon nitride to 20mL 4mol / L acetic acid, stir for 90min; sonicate for 30min to obtain solution A; add bismuth chloride and sodium metavanadate with a molar ratio of 1:1 into solution A to control the graphite phase The mass ratio of carbon nitride and bismuth vanadate is 4:1; the pH of the solution is adjusted to 5 with 2mol / L sodium hydroxide; the mixed solution is transferred to a polytetrafluoroethylene reactor and heated in an oven at 190°C for 12h; Centrifuge at a speed of 1 min for 5 min, and repeat 3 times; wash the precipitate 3 times with deionized water and absolute ethanol, and dry overnight at 60°C to obtain bismuth vanadate-doped graphite-phase carbon nitride nanosheets. Its UV-Vis diffuse reflectance spectrum is as follows image 3 As shown, the absorption wavelength of UTCN is around 420nm, and the BiVO 4 It has strong absorption in the visible light region, by adding BiVO 4 Introduce to UTCN to build UTCN / BiVO 4 Composite ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com