Method for producing X65 acid-resistant pipeline steel plate used under low-cost and ultralow-temperature conditions through curling furnace

An ultra-low temperature, low-cost technology, applied in the direction of reducing gas emissions, can solve the problems of low-cost process, difficult to ensure the ultra-low temperature performance of thin acid-resistant steel plate, anti-HIC performance, difficult to ensure use, etc., to ensure grain structure, excellent ultra-low temperature and anti-acid properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

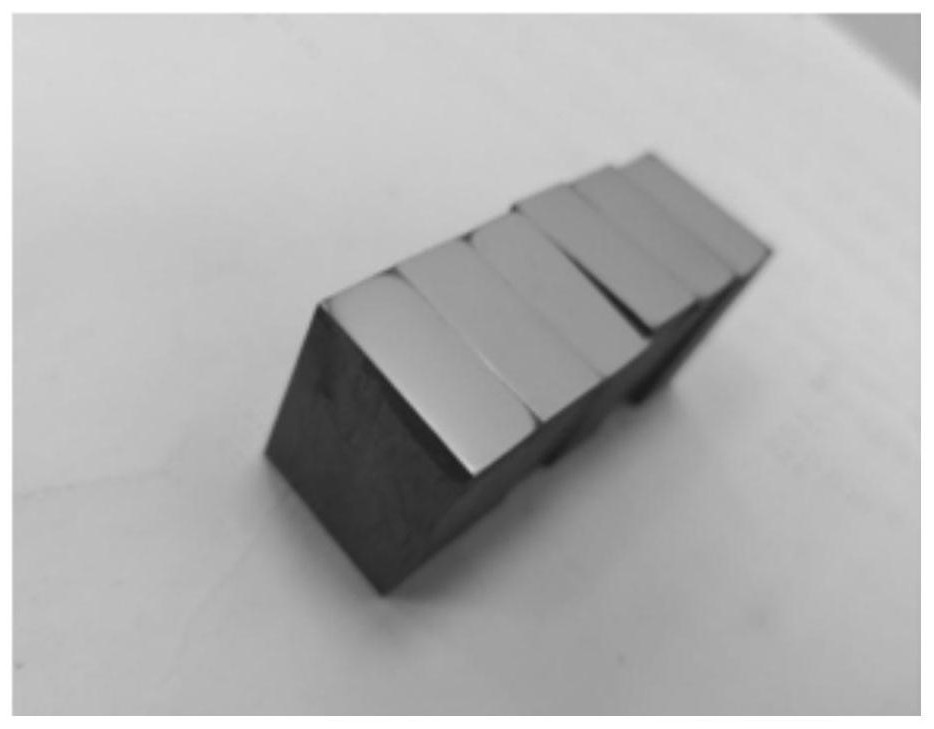

Image

Examples

Embodiment 1-2

[0041] The manufacturing process of X65MS pipeline steel plate: KR hot metal pretreatment (desulfurization in advance)—BOF smelting—RH vacuum degassing—LF refining—RH vacuum degassing—continuous casting into 150mm thick continuous casting slab—continuous casting slab with cover and slow cooling— Continuous casting slab inspection and cleaning—casting slab reheating—high pressure water descaling—rolling—flying shear section—ACC cooling—straightening—steel plate shearing—inspection and warehousing, and the manufacture of X65MS acid-resistant pipeline steel plates used under ultra-low temperature conditions.

[0042] The concrete process of above-mentioned heating, rolling, cooling is: the 150mm thick continuous casting slab is heated to 1180 ℃, soaking section insulation 50min (embodiment 1) or 150mm thickness continuous casting slab is heated to 1180 ℃, soaking section insulation 40min ( Embodiment 2), use high-pressure water descaling after the continuous casting slab is releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com