Solar vacuum heat-collecting tube with fluid mixer

A vacuum heat collector tube and mixer technology, which is applied to solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problem of uneven heat flux density of solar collector tubes, optimize heat collection performance, strengthen convective heat transfer, prevent cracked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

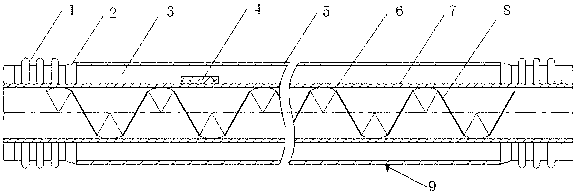

[0019] Such as figure 1 As shown, the present invention is a solar vacuum heat collecting tube with a flow mixer, comprising a glass outer tube 5, a metal tube 6 packaged on the inner surface of the glass outer tube 5 and coated with a selective sunlight-absorbing coating 7, arranged on a glass The two ends of the outer tube include a metal bellows 1 and a Kovar tube 2 packaging device, and a vacuum chamber 3 is formed between the glass outer tube 5 and the metal tube 6. It is characterized in that a flow mixer 8 is arranged inside the metal tube 6, increasing The mixing of the fluids on the cross section makes the temperature of the fluids in the metal tube 6 uniform.

[0020] Such as figure 2 As shown, the flow mixer 8 adopts a baffle structure. After the heat-carrying fluid flows through the baffle mixer, the flow direction of the fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com