Wear-resisting small eccentric V-ball regulating valve special for salt chemical engineering

A small eccentric, salt chemical technology, applied in the field of instrument control, can solve the problems of entering the gap between the valve shaft and the bushing, crystallization corrosion of the cavity, erosion of the valve body and valve trim, etc., to avoid temperature difference and processing deformation, prevent Salt material crystallization or scaling, the effect of increasing the leakage level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings and implementation methods.

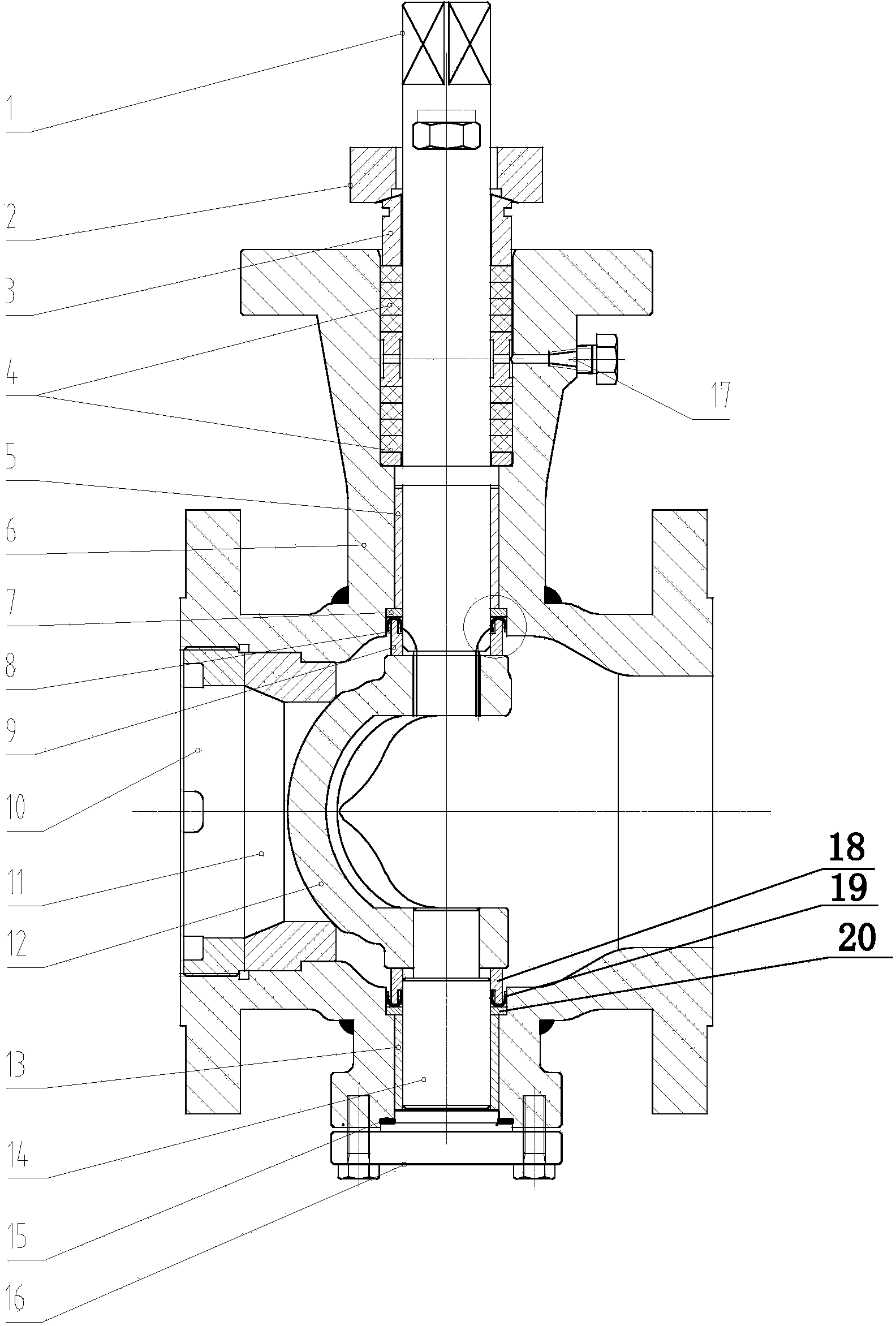

[0030] As shown in the figure: the special wear-resistant small eccentric V ball regulating valve for salt chemical industry, including transmission shaft 1, packing pressure plate 2, packing gland 3, packing seal assembly 4, upper bushing 5, valve body 6, first support ring 7. The first C-shaped sealing ring 8, the first distance adjusting pad 9, the pressure ring 10, the valve seat 11, the small eccentric valve ball 12, the lower bushing 13, the driven shaft 14, the sealing gasket 15, the bottom flange 16. Oil filling port 17, second distance adjusting pad 18, second C-shaped sealing ring 19, second supporting ring 20 and other parts.

[0031] A stuffing box is processed on the valve body 6, and the stuffing sealing assembly 4, the stuffing gland 3, and the stuffing plate 2 are sequentially installed in the stuffing box, and are tightly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com