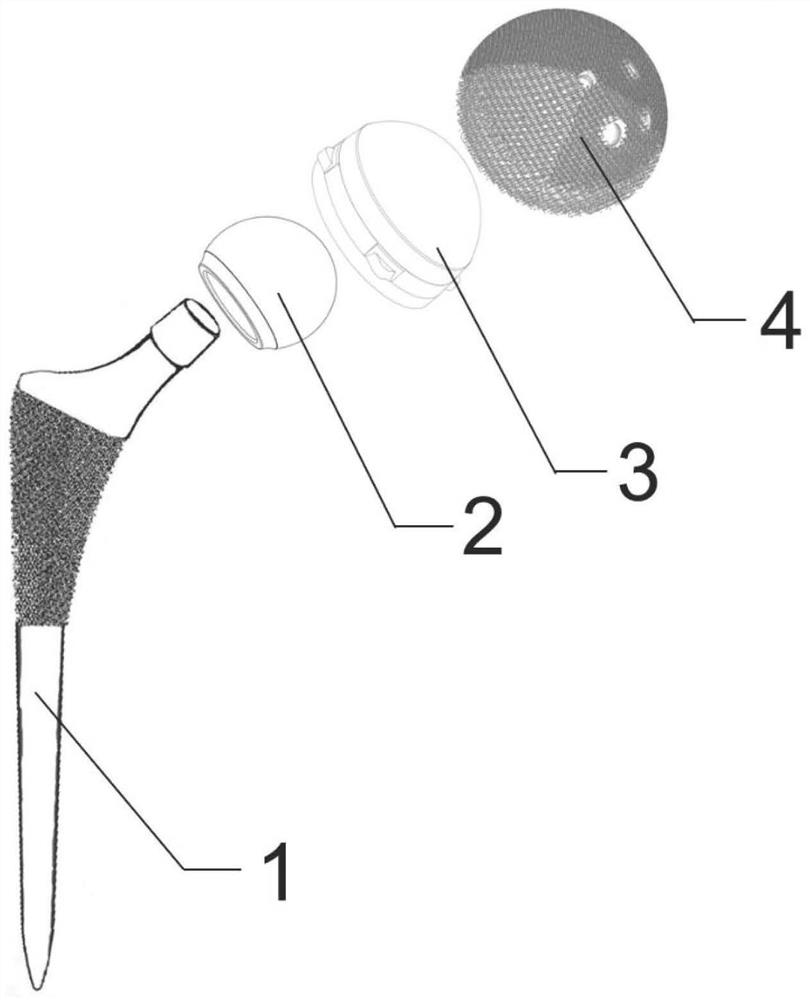

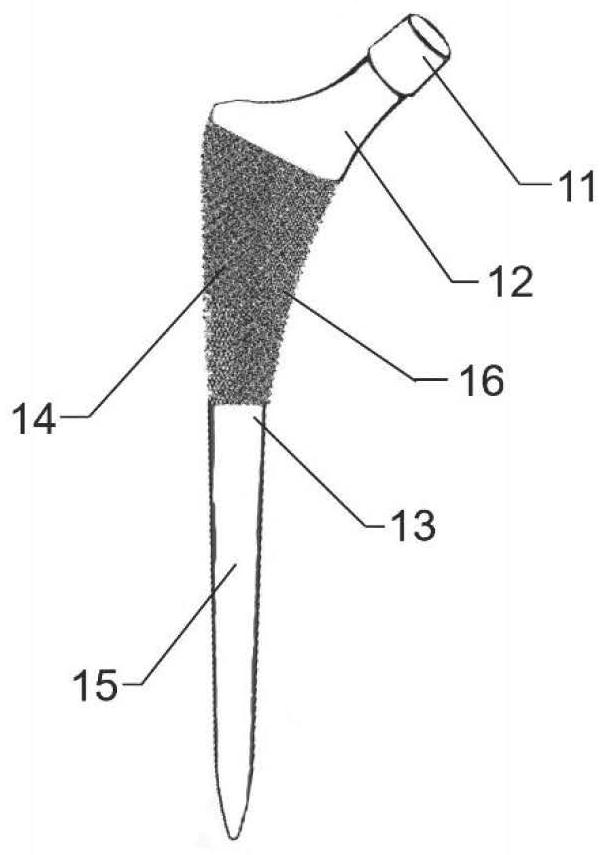

Zirconium-niobium alloy hip joint prosthesis system containing oxide layer and preparation method

A hip joint prosthesis, zirconium niobium alloy technology, applied in the direction of hip joints, prostheses, joint implants, etc., can solve problems such as uneven microstructure, poor mechanical properties, surface coating peeling off, etc., to achieve excellent Bone ingrowth and biocompatibility, excellent biocompatibility, the effect of achieving super wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for preparing a zirconium-niobium alloy hip joint prosthesis system containing an oxide layer, comprising the following steps:

[0064] 1) Preparation of acetabular cup and femoral stem:

[0065] 1-1) The first intermediate product of the acetabular cup and the first intermediate product of the femoral stem are respectively obtained by 3D printing with zirconium-niobium alloy powder as the raw material, and the two first intermediate products are put into a hot isostatic pressing furnace, Under the protection of helium, raise the temperature to 1250°C, place it at 180MPa for 3 hours at a constant temperature, drop to normal pressure, and take it out with the furnace cooling to below 200°C to obtain two second intermediate products;

[0066] 1-2) Place the two second intermediate products in a programmed cooling box to cool down to -80°C at a rate of 1°C / min, place them at a constant temperature for 10 hours, take them out of the programmed cooling box, and plac...

Embodiment 2

[0085] A method for preparing a zirconium-niobium alloy hip joint prosthesis system containing an oxide layer, comprising the following steps:

[0086] 1) Preparation of acetabular cup and femoral stem:

[0087] 1-1) The first intermediate product of the acetabular cup and the first intermediate product of the femoral stem are respectively obtained by 3D printing with zirconium-niobium alloy powder as the raw material, and the two first intermediate products are put into a hot isostatic pressing furnace, Under the protection of argon, raise the temperature to 1325°C, place it at a constant temperature of 160MPa for 2 hours, drop to normal pressure, and take it out with the furnace cooling to below 200°C to obtain two second intermediate products;

[0088] 1-2) Place the two second intermediate products in a programmed cooling box to cool down to -100 °C at a rate of 1 °C / min, keep them at a constant temperature for 7 hours, take them out of the programmed cooling box, and plac...

Embodiment 3

[0107] The preparation method of the zirconium-niobium alloy hip joint prosthesis system containing oxide layer is characterized in that it comprises the following steps:

[0108] 1) Preparation of acetabular cup and femoral stem:

[0109] 1-1) The first intermediate product of the acetabular cup and the first intermediate product of the femoral stem are respectively obtained by 3D printing with zirconium-niobium alloy powder as the raw material, and the two first intermediate products are put into a hot isostatic pressing furnace, Under the protection of argon, raise the temperature to 1400°C, place it at a constant temperature of 140MPa for 1 hour, drop to normal pressure, and take it out with the furnace cooling to below 200°C to obtain two second intermediate products;

[0110] 1-2) Place the two second intermediate products in a programmed cooling box to cool down to -120 °C at a rate of 1 °C / min, keep them at a constant temperature for 5 hours, take them out of the progr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com