A lithium-sulfur battery

A lithium-sulfur battery and electrolyte technology, applied in the manufacture of lithium batteries, secondary batteries, electrolyte batteries, etc., can solve problems affecting battery cycle performance, loss of active materials, and damage to lithium negative electrodes, improve battery capacity, and prevent corrosion. Destruction and discharge capacity guarantee effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

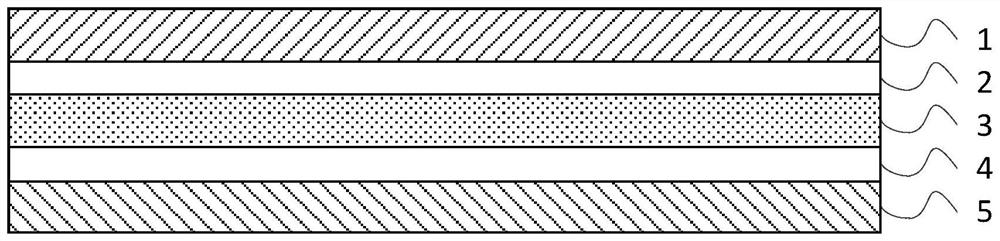

[0062] The structure of the lithium-sulfur battery of this embodiment is as follows image 3 shown.

[0063] The preparation method of the lithium-sulfur battery of this embodiment comprises the following steps:

[0064] 1) Preparation of sulfur-containing cathode

[0065] Ketjen black (EC-600JD, Lion King of Japan) and sulfur were mixed and melted and cooled to obtain a carbon-sulfur compound with a sulfur content of 87 wt%;

[0066] Mix the carbon-sulfur compound with deionized water, add SUPER P, sodium carboxymethyl cellulose (CMC), and styrene-butadiene rubber (SBR), and stir to obtain a functional layer slurry; wherein, the mass of the carbon-sulfur compound The fraction is 92%, the mass fraction of SUPER P is 3%, the mass fraction of sodium carboxymethyl cellulose is 2%, and the mass fraction of styrene-butadiene rubber is 3%;

[0067] The above-mentioned functional layer slurry is coated on the functional surface of aluminum foil with a thickness of 15 microns, so t...

Embodiment 2

[0078] Compared with the lithium-sulfur battery in Example 1, the difference between the lithium-sulfur battery in this example and the lithium-sulfur battery in Example 1 is that the composition of the first electrolyte is Li 2 S 8 :DOL:DME mass ratio is 25:45:30.

Embodiment 3

[0080] Compared with the lithium-sulfur battery in Example 1, the difference between the lithium-sulfur battery in this example and the lithium-sulfur battery in Example 1 is that the composition of the first electrolyte is Li 2 S 8 :DOL:DME mass ratio is 45:25:30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com