Hydrogen concentration measuring device resistant to high temperature, high pressure, high humidity and radiation and hydrogen measuring probe

A measuring probe and high-temperature-resistant technology, which can be used in measuring devices, greenhouse gas reduction, climate sustainability, etc., can solve the problems of monitoring hydrogen concentration, unbearable temperature, and low safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

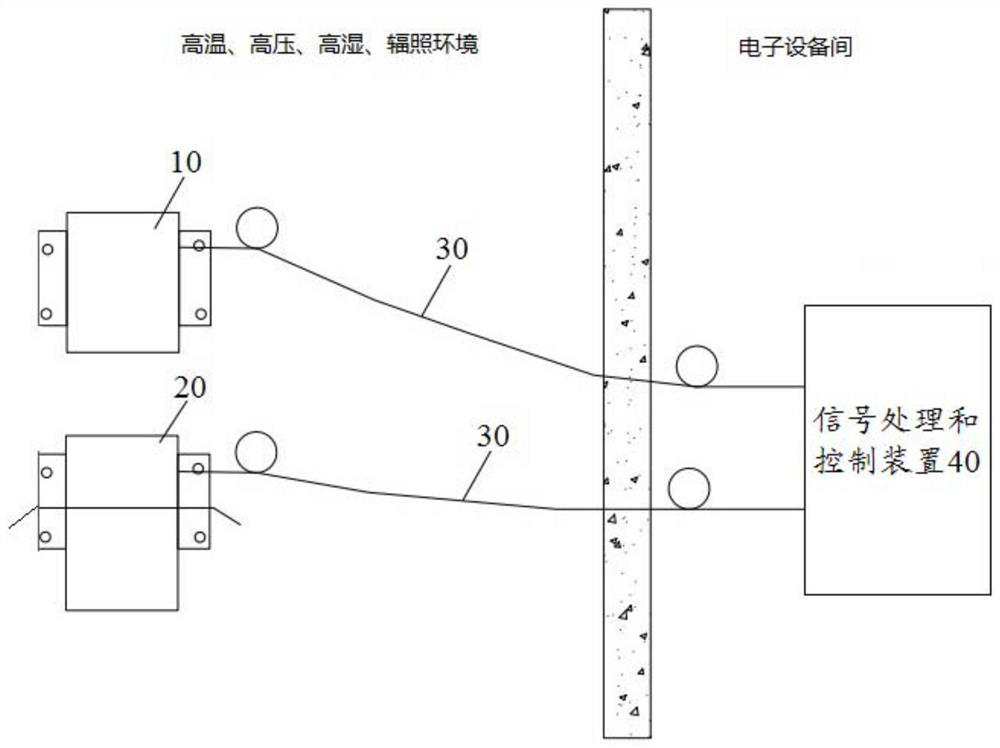

[0040] see figure 1 , the hydrogen concentration measuring device of the present invention resistant to high temperature, high pressure and high humidity radiation comprises:

[0041] A pressure sensor 10 for measuring the pressure at the position to be measured;

[0042] A hydrogen measuring probe 20 for measuring the hydrogen partial pressure at the position to be measured;

[0043] The signal processing and control device 40 connected to the pressure sensor 10 and the hydrogen gas measuring probe 20 through the cable 30, the signal processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com