High-fiber rice bran instant powder and preparation method thereof

A technology of instant powder and high-fiber rice, which is applied in the directions of food ingredients as thickeners, food ingredients as taste improvers, and functions of food ingredients, etc., can solve the problems of high calories, loss of grain texture, loss of dietary fiber, etc. Good solubility, retention of nutrients, and improved antioxidant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

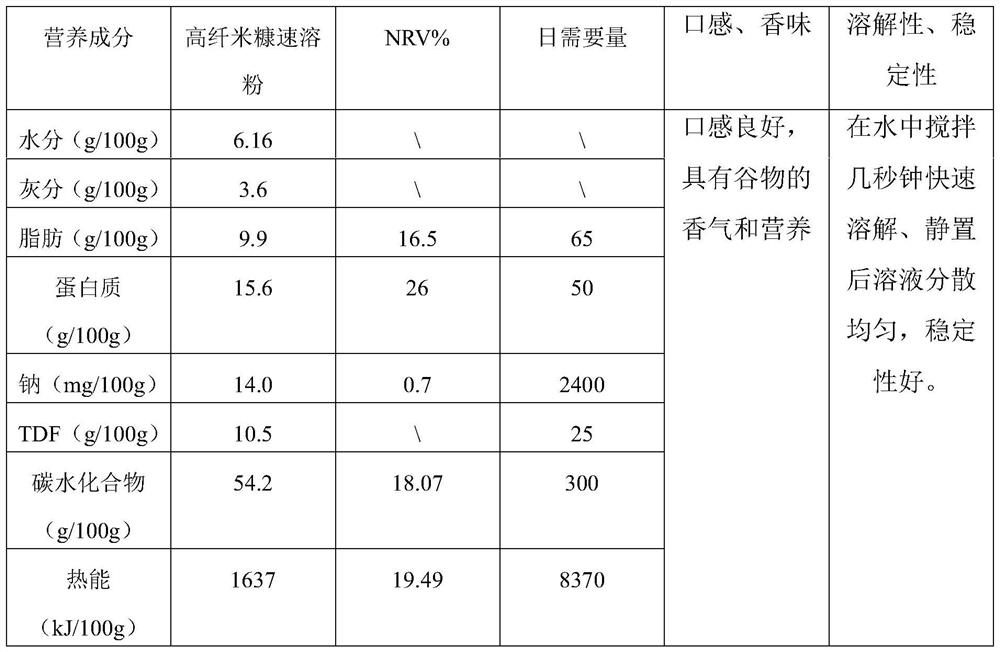

Embodiment 1

[0036] The preparation of high-fiber rice bran instant powder comprises the following steps:

[0037] (1) Preparation of defatted rice bran: grind fresh rice bran with a pulverizer, and pass through a 60-mesh sieve to obtain rice bran powder. Add n-hexane with the volume of n-hexane equal to 3 times the mass of rice bran, degrease for 30 minutes, dry and store in sealed bags for later use.

[0038] (2) Preparation of modified rice bran: inoculate lactic acid bacteria on 80 mL of liquid MRS medium, incubate at 37°C for 16 h; centrifuge at 4000 rpm / min for 20 min, wash the precipitate once with normal saline, and finally dissolve it in 50 mL of sterile water to obtain a suspension of lactic acid bacteria liquid. Based on the mass of defatted rice bran, add 2% highly active yeast, sterile water and lactic acid bacteria suspension to the defatted rice bran, stir evenly, and incubate in a constant temperature incubator at 37° C. for 24 hours. After the fermentation, add 0.5% xyla...

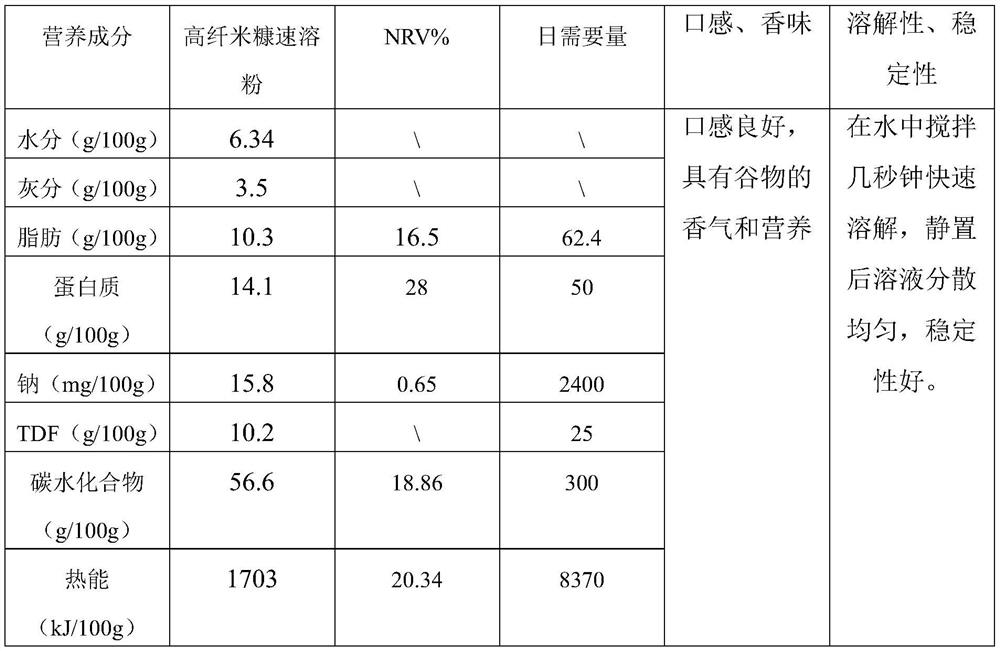

Embodiment 2

[0043] (1) Preparation of defatted rice bran: grind fresh rice bran with a pulverizer, and pass through a 60-mesh sieve to obtain rice bran powder. Add n-hexane with the volume of n-hexane equal to 5 times the mass of rice bran, degrease for 30 minutes, dry and store in sealed bags for later use.

[0044](2) Preparation of modified rice bran: Inoculate lactic acid bacteria on 80 mL of liquid MRS medium, incubate at 37°C for 20 h; centrifuge at 5000 rpm / min for 10 min, wash the precipitate three times with normal saline, and finally dissolve it in 50 mL of sterile water to obtain a suspension of lactic acid bacteria liquid. Based on the mass of defatted rice bran, add 3% highly active yeast, sterile water and lactic acid bacteria suspension to the defatted rice bran, stir evenly, and incubate in a constant temperature incubator at 37° C. for 24 hours. After the fermentation, add 3% xylanase of the mass of defatted rice bran and 5% cellulase of the mass of defatted rice bran to...

Embodiment 3

[0049] Embodiment is different from Example 1 in the addition of sucrose ester and monoglyceride in step (4), wherein the addition of sucrose ester and monoglyceride is 0.25% altogether, and the addition of monoglyceride and sucrose ester The ratio is 2:8 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com