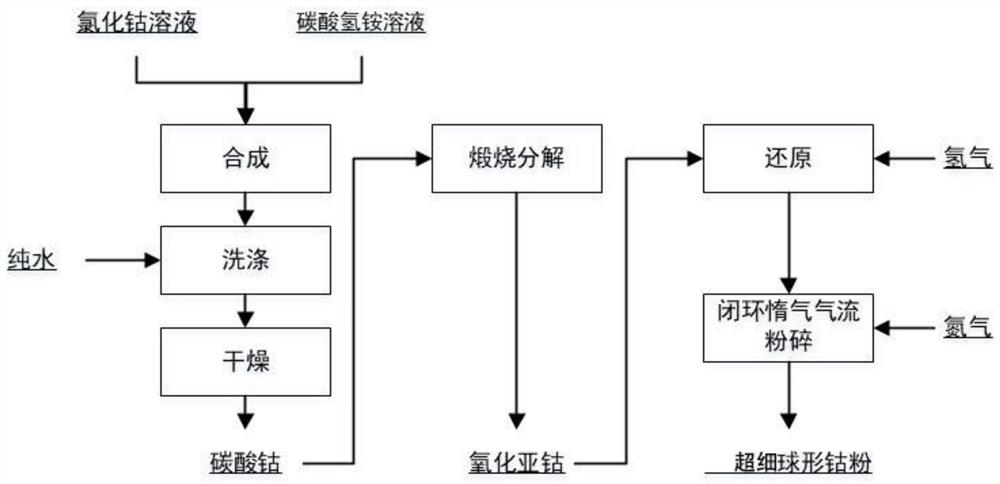

Preparation method of superfine spherical cobalt powder

A spherical, cobalt powder technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of difficult to produce ultra-fine cobalt powder, large particle size of cobalt powder, short preparation process, etc. control, uniform particle size distribution and good flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

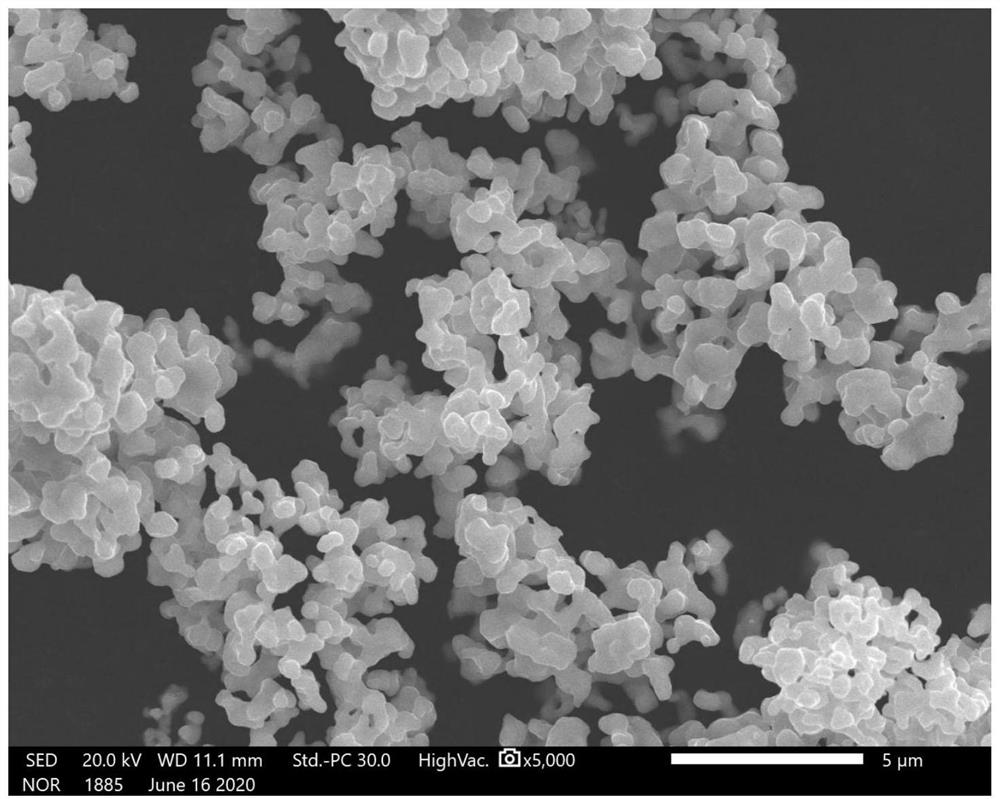

Embodiment 1

[0033] Step 1: Use pure water to prepare ammonium bicarbonate solution and cobalt chloride solution respectively. The concentration of the ammonium bicarbonate solution is 180g / L, and the cobalt chloride solution is 90g / L. Put the ammonium bicarbonate solution into the reactor and heat to 44°C , and then under the condition of stirring and heat preservation, the cobalt chloride solution is added dropwise into the reactor to react with ammonium bicarbonate to synthesize cobalt carbonate precipitation, and the pH value at the end of the reaction is 6.8.

[0034] Step 2: The cobalt carbonate precipitate was washed with pure water at 70°C, slurried, and dried in a flash drying oven to obtain cobalt carbonate powder at a drying temperature of 120°C.

[0035] Step 3: Put the cobalt carbonate powder into the rotary kiln, and heat and decompose it in an oxygen-free state to obtain cobaltous oxide. In the calciner, a protective inert gas nitrogen with a slight positive pressure of 10Pa ...

Embodiment 2

[0039] Step 1: Use pure water to prepare ammonium bicarbonate solution and cobalt chloride solution respectively. The concentration of the ammonium bicarbonate solution is 190g / L, and the cobalt chloride solution is 95g / L. Put the ammonium bicarbonate solution into the reactor and heat to 44°C , and then under the condition of stirring and heat preservation, the cobalt chloride solution is added dropwise into the reactor to react with ammonium bicarbonate to synthesize cobalt carbonate precipitate, and the pH value at the end of the reaction is 6.9.

[0040] Step 2: The cobalt carbonate precipitate was washed with pure water at 75°C, slurried, and dried in a flash drying oven to obtain cobalt carbonate powder at a drying temperature of 120°C.

[0041] Step 3: Put the cobalt carbonate powder into the rotary kiln, and heat and decompose it in an oxygen-free state to obtain cobaltous oxide. In the calciner, a protective inert gas nitrogen with a slight positive pressure of 14Pa is...

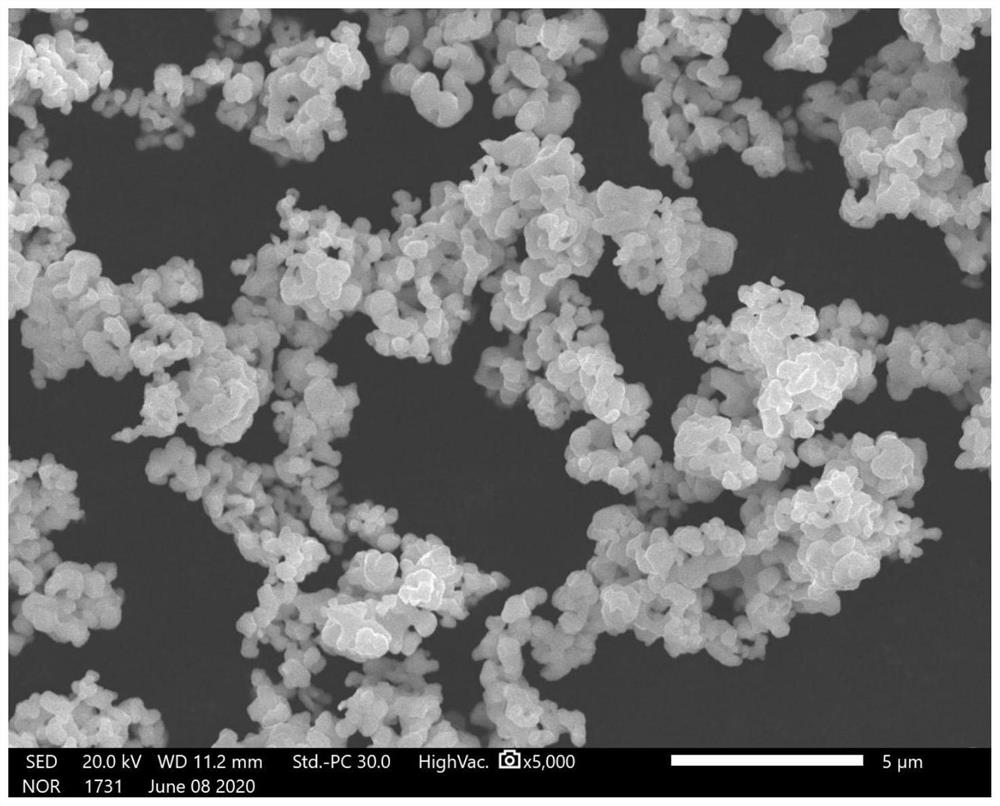

Embodiment 3

[0045] Step 1: Use pure water to prepare ammonium bicarbonate solution and cobalt chloride solution respectively. The concentration of ammonium bicarbonate solution is 200g / L, and the concentration of cobalt chloride solution is 120g / L. Put the ammonium bicarbonate solution into the reactor and heat to 46°C , and then under the condition of stirring and heat preservation, the cobalt chloride solution is added dropwise into the reactor to react with ammonium bicarbonate to synthesize cobalt carbonate precipitate, and the pH value at the end of the reaction is 7.0.

[0046] Step 2: The cobalt carbonate precipitate was washed with pure water at 80°C, slurried, and dried in a flash drying oven to obtain cobalt carbonate powder at a drying temperature of 120°C.

[0047] Step 3: Put the cobalt carbonate powder into a rotary kiln, and heat and decompose it in an oxygen-free state to obtain cobaltous oxide. In the calciner, a protective inert gas nitrogen with a slight positive pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com