Water treatment reactor

A reactor, water treatment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

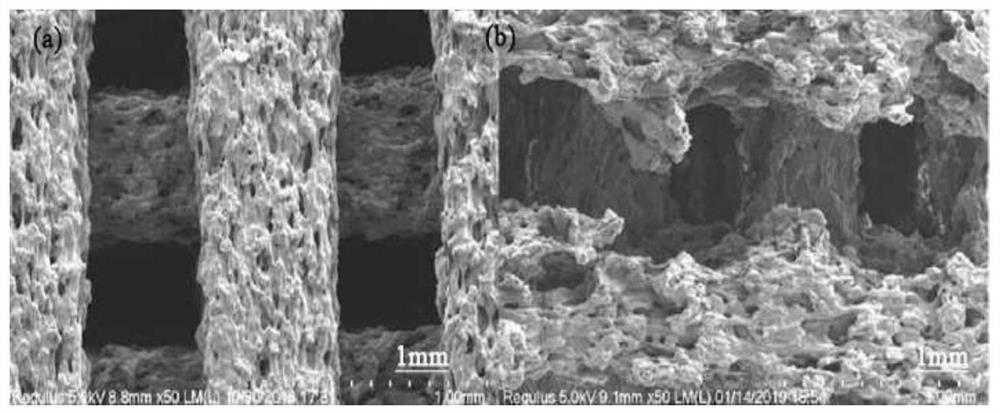

Image

Examples

Embodiment 1

[0024] A water treatment reactor, specifically comprising the steps of:

[0025] Modified graphene oxide is obtained through the following steps:

[0026] 1) graphene oxide is added to distilled water, then citric acid and urea are added, wherein the mass ratio of graphene oxide, citric acid and urea is 3.69:1.12:0.96, stirred at room temperature for 30min, then moved into the middle of the autoclave, in the React at 180°C for 5h, cool, filter and dry.

[0027] 2) the graphene oxide obtained in step 1) is mixed with β-cyclodextrin, wherein the mass ratio of step 1) graphene oxide and β-cyclodextrin is 1:0.31, and then added to the tube furnace, at 550 Calcined at ℃ for 3h, and obtained modified graphene oxide after cooling.

[0028] S1: Place polylactic acid and chitosan in a drying oven and dry at 50°C for 6 hours, take it out after cooling, and mix with polyadipate and dibutyl terephthalate. The mass ratio of acid and dibutyl terephthalate is 66:19:12:13, and then added t...

Embodiment 2

[0031] A water treatment reactor, specifically comprising the steps of:

[0032] Modified graphene oxide is obtained through the following steps:

[0033] 1) Graphene oxide is added to distilled water, then citric acid and urea are added, wherein the mass ratio of graphene oxide, citric acid and urea is 5.74:1.46:1.21, stirred at room temperature for 50min, then moved into the middle of the autoclave, in the React at 200°C for 9h, cool, filter and dry.

[0034] 2) the graphene oxide obtained in step 1) is mixed with β-cyclodextrin, wherein the mass ratio of step 1) graphene oxide and β-cyclodextrin is 1:0.37, and then added to the tube furnace, at 600 Calcined at ℃ for 4h, and obtained modified graphene oxide after cooling.

[0035] S1: Place polylactic acid and chitosan in a drying oven at 65°C for 10 hours, take it out after cooling, and mix with polyadipate and dibutyl terephthalate, among which polylactic acid, chitosan, and polyadipate The mass ratio of acid and dibuty...

Embodiment 3

[0038] A water treatment reactor, specifically comprising the steps of:

[0039] Modified graphene oxide is obtained through the following steps:

[0040] 1) graphene oxide is added to distilled water, then citric acid and urea are added, wherein the mass ratio of graphene oxide, citric acid and urea is 4.44:1.25:1.06, stirred at room temperature for 40min, then moved into the middle of the autoclave, in the React at 190°C for 6h, cool, filter and dry.

[0041] 2) mixing the graphene oxide and β-cyclodextrin obtained in step 1), wherein the mass ratio of step 1) graphene oxide and β-cyclodextrin is 1:0.31~0.37, and then adding it into a tube furnace, Calcined at 550°C for 3.5h, and cooled to obtain modified graphene oxide.

[0042]S1: Place polylactic acid and chitosan in a drying oven and dry at 55°C for 8 hours, take it out after cooling, and mix with polyadipate and dibutyl terephthalate. The mass ratio of acid and dibutyl terephthalate is 70:20:14:15, and then added to ...

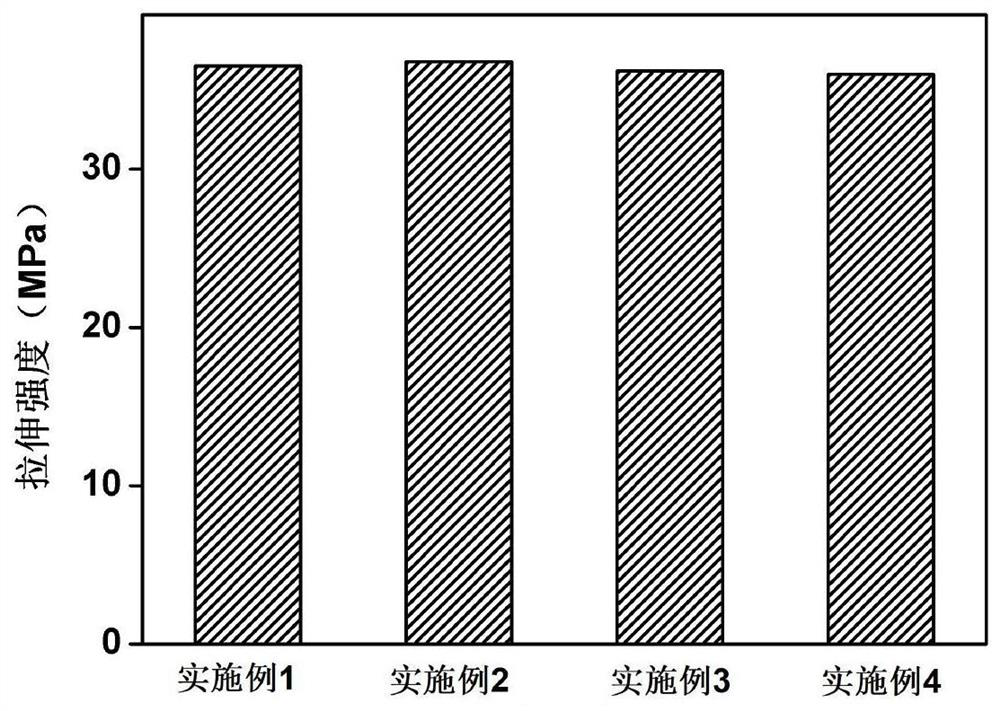

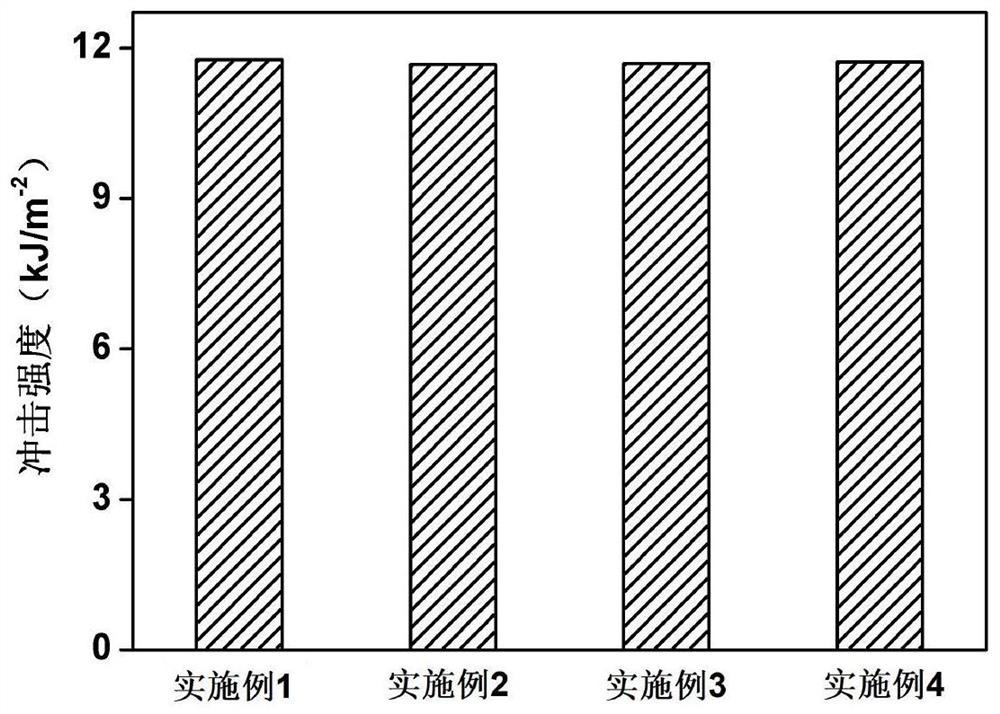

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com