Film acoustic resonator and manufacturing method thereof

A technology of acoustic wave resonator and thin-film acoustic wave, applied in the direction of electrical components, impedance network, etc., can solve the problems of reducing equipment performance, electromagnetic interference, and small ratio, and achieve the effect of improving structural strength and suppressing external electromagnetic radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

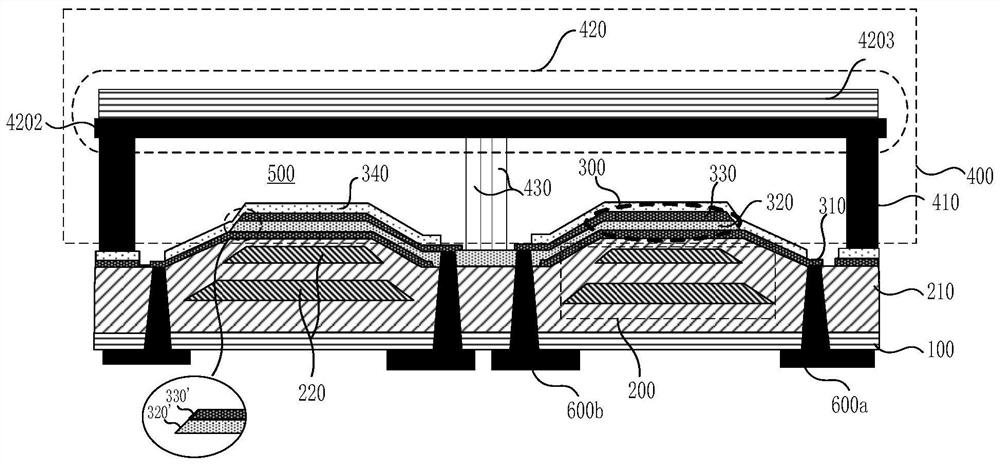

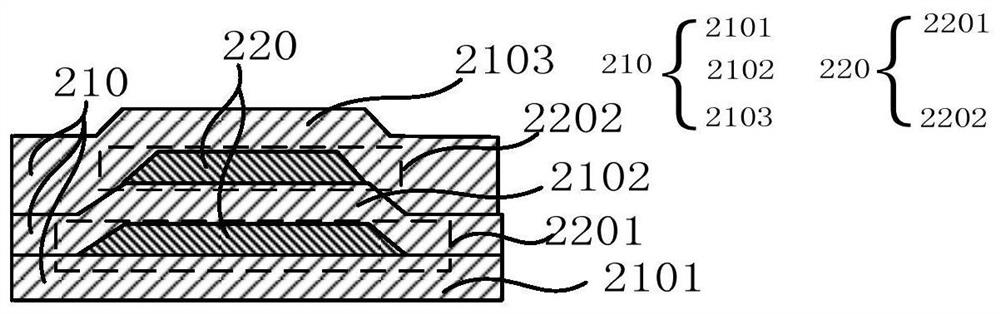

[0033] This embodiment provides a thin film acoustic resonator, wherein the thin film acoustic resonator is a solid assembly type resonator, figure 1 A schematic structural view of the thin film acoustic resonator of Embodiment 1 is shown, figure 2 A schematic structural diagram showing the structure of the Bragg reflection layer of Embodiment 1, please refer to figure 1 with figure 2 , the thin film acoustic resonator consists of:

[0034] A first substrate 100 containing an acoustic reflection structure; (in this embodiment, the acoustic reflection structure is a Bragg reflection layer structure, and may be a cavity structure in other embodiments)

[0035] The acoustic wave resonator unit 300 (shown in the elliptical dotted line box), at least partly located on the acoustic reflection structure, the acoustic wave resonator unit 300 sequentially includes a first electrode 310, a piezoelectric layer 320 and a second electrode 330 from bottom to top;

[0036] The substrat...

Embodiment 2

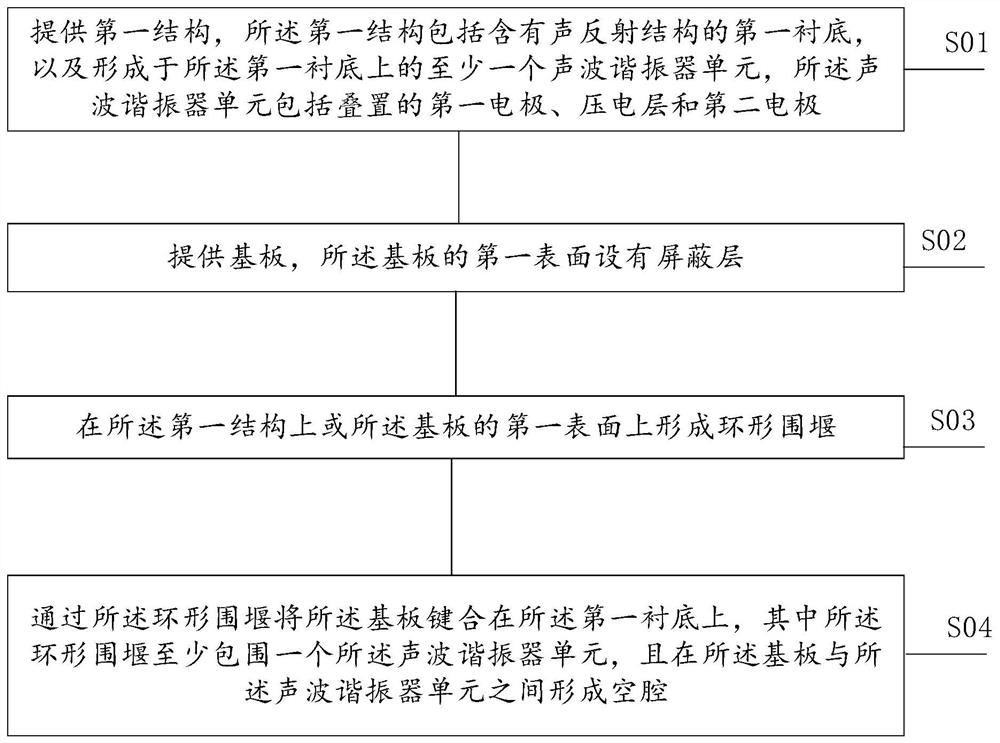

[0052] An embodiment of the present invention provides a method for manufacturing a thin-film acoustic wave resonator, please refer to image 3 , image 3 It is a flow chart of a manufacturing method of a thin film acoustic wave resonator according to an embodiment of the present invention, and the manufacturing method includes:

[0053] S01: Provide a first structure, the first structure includes a first substrate including an acoustic reflection structure, and at least one acoustic resonator unit formed on the first substrate, the acoustic resonator unit includes a stack The first electrode, the piezoelectric layer and the second electrode;

[0054] S02: providing a substrate, the first surface of the substrate is provided with a shielding layer;

[0055] S03: forming an annular cofferdam on the first structure or on the first surface of the substrate;

[0056] S04: Bond the substrate to the first substrate through the annular dam, wherein the annular dam surrounds at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com