Preparation method of high-corrosion-resistance modified epoxy resin composite coating

A technology of epoxy resin and composite coating, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve problems such as structural defects, and achieve the effect of increasing crosslinking density, promoting protective performance, and increasing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method for a highly corrosion-resistant modified epoxy resin composite coating, comprising the following steps:

[0026] (1) Preparation of MOF nanomaterials: Dissolve the metal salt and imidazole ligand in anhydrous methanol, stir for 2-3 hours to obtain a white emulsion, centrifuge to obtain a white solid, and then alternately wash with methanol and deionized water for 3-3 hours 5 times, and then vacuum-dried at 60-80°C to obtain white powdery MOF nanomaterials;

[0027] Metal-Organic Framework (MOF for short) is a porous crystal material formed by metal ion clusters and inorganic ligands or organic ligands under certain conditions. The MOF nano material of the invention is prepared by using imidazole ligand and metal salt as raw materials. In the present invention, the diversification of imidazole ligands is utilized, and the size of the MOF material and the amount of active hydrogen are regulated by using imidazole ligands with benzene rings and amino...

Embodiment 1

[0045] (1) Preparation of ZIF-8 material: 0.5g Zn(NO 3 ) 2 ·6H 2O and 0.55g 2-methylimidazole were dissolved in 50ml of anhydrous methanol, wherein the molar ratio of zinc ions and 2-methylimidazole was 1:4, stirred at room temperature on a magnetic stirrer for 2h, and the obtained white emulsion, Then centrifuged and alternately washed 4 times with anhydrous methanol and deionized water to obtain a white solid, and finally dried the obtained white solid at 70° C. for 12 hours to obtain ZIF-8 in the form of white powder;

[0046] (2) Preparation of modified epoxy resin: mixing epoxy resin, ZIF-8 and diluent with a mass ratio of 10:0.5:8, wherein the diluent is a mixture of xylene and n-butanol, and xylene and n-butyl The mass ratio of alcohol is 2:1; ball mill and stir for 0.5h, then add 80g of polyamide 650 curing agent for every 100g of epoxy resin E-44, stir for 10min, mix well and then vacuumize to obtain modified epoxy resin;

[0047] (3) Coating film: apply the modifi...

Embodiment 2

[0057] (1) Preparation of aminated ZIF-8 material: 0.5g Zn(NO 3 ) 2 ·6H 2 O, 0.3g 2-methylimidazole and 0.4g 2-aminobenzimidazole were dissolved in 50ml of anhydrous methanol. At this time, the molar ratio of zinc ion and imidazole group was 1:4, and stirred at room temperature on a magnetic stirrer for 3h, The obtained white emulsion was centrifuged and washed alternately with anhydrous methanol and deionized water for 4 times to obtain a white solid, and finally the obtained white solid was dried at 70° C. for 12 hours to obtain white powdered aminated ZIF-8;

[0058] (2) Aminated ZIF-8 modified epoxy resin: mix epoxy resin, aminated ZIF-8 and diluent with a mass ratio of 10:2:8.5, wherein the diluent is a mixture of xylene and n-butanol , and the mass ratio of xylene and n-butanol is 2:1; the ball mill is stirred for 0.5h, and then 25g of polyamide 651 curing agent is added for every 100g of epoxy resin E-51, stirred for 10min, mixed evenly and vacuumized to obtain the im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

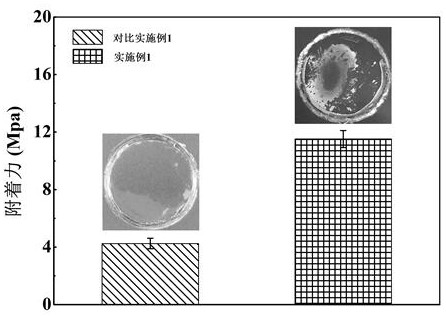

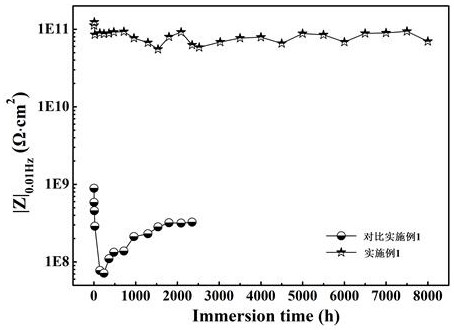

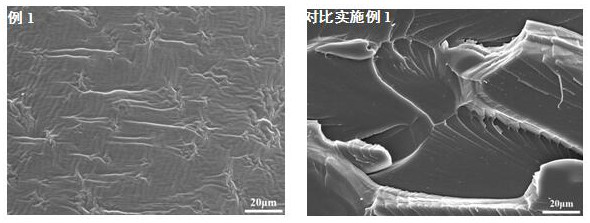

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com