Method for preparing multiple Pickering emulsion from crystalline block copolymer micelles

A technology of block copolymers and copolymers, applied in the direction of emulsion delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems that solid particles are not easy to be degraded and harmful, and overcome the excessive oil-soluble emulsifier , slow and controlled release, good emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Block copolymer PEG 2k -PCL 19.4k and PCL 1.9k -PEG 20k -PCL 1.9k Preparation of:

[0061] PEG 2k -PCL 19.4k Preparation of block copolymer: 0.5g polyethylene glycol monomethyl ether (average molecular weight is 2000Da), 5g ε-caprolactone monomer, 0.028g stannous octoate are placed in a dry flask, under argon protection , reacted at 120°C for 12 hours; after the reaction, the reaction mixture was dropped into ice n-hexane to precipitate, filtered and dried to obtain PEG 2k -PCL 19.4k block copolymers.

[0062] PCL 1.9k -PEG 20k -PCL 1.9k The preparation of block copolymer: 2.5g polyethylene glycol (average molecular weight is 20000Da), the epsilon-caprolactone monomer of 0.5g, 0.015g stannous octoate are placed in dry flask, under argon protection, in React at 120°C for 12 hours; after the reaction, drop the reaction mixture into ice n-hexane to precipitate, filter and dry to obtain PCL 1.9k -PEG 20k -PCL 1.9k block copolymers.

[0063] The obtained ...

Embodiment 2

[0069] (1) Block copolymer PCL 5.1k -PEG 8k -PCL 5.1k 、PDLA5.8k -PEG 5k -PDLA 5.8k and PLLA 3k -PEG 10k -PLLA 3k Preparation of:

[0070] PCL 5.1k -PEG 8k -PCL 5.1k Preparation of block copolymer: 4g polyethylene glycol (average molecular weight is 8000Da), 5g ε-caprolactone monomer, 0.045g stannous octoate are placed in a dry flask, under the protection of argon, at 120 ℃ React for 12 hours; after the reaction, drop the reaction mixture into ice n-hexane to precipitate, filter and dry to obtain PCL 5.1k -PEG 8k -PCL 5.1k block copolymers.

[0071] PDLA 5.8k -PEG 5k -PDLA 5.8k The preparation of block copolymer: 2.08g polyethylene glycol (average molecular weight is 5000Da), the dextrolactide monomer of 5g, 0.035g stannous octoate are placed in dry flask, under argon protection, at 120 ℃ for 12 hours; after the reaction, drop the reaction mixture into ice n-hexane to precipitate, filter and dry to obtain PDLA 5.8k -PEG 5k -PDLA 5.8k block copolymers.

[00...

Embodiment 3

[0079] (1) Block copolymer PEG 2k -PGA 5.2k 、PEG 5k -PDLA 8k and PLLA 3.7k -PEG 5k -PLLA 3.7k Preparation of:

[0080] PEG 2k -PGA 5.2k The preparation of block copolymer: 2g polyethylene glycol monomethyl ether (average molecular weight is 2000Da), the glycolide monomer of 5g, 0.035g stannous octoate are placed in the flask of drying, under argon protection, at 120 ℃ for 12 hours; after the reaction, drop the reaction mixture into ice n-hexane to precipitate, filter and dry to obtain PEG 2k -PGA 5.2k block copolymers.

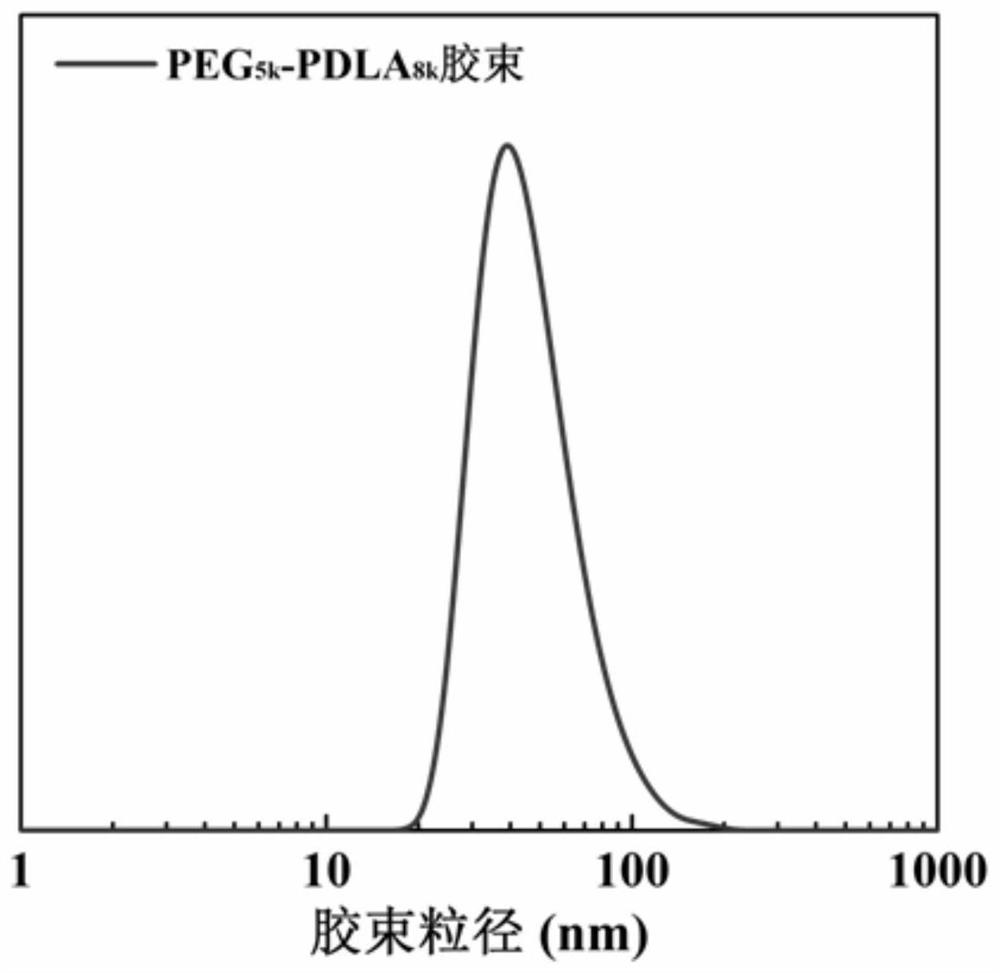

[0081] PEG 5k -PDLA 8k Preparation of block copolymer: 3.13g polyethylene glycol monomethyl ether (average molecular weight is 5000Da), 5g dextrolactide monomer, 0.041g stannous octoate are placed in a dry flask, under argon protection , reacted at 120°C for 12 hours; after the reaction, the reaction mixture was dropped into ice n-hexane to precipitate, filtered and dried to obtain PEG 5k -PDLA 8k block copolymers.

[0082] PLLA 3.7k -PEG 5k ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com