A corrosion-resistant high-strength Fe-rich multi-component alloy and preparation method thereof

A multi-component, corrosion-resistant technology, applied in the field of metal materials, can solve problems such as low strength and poor corrosion resistance, and achieve the effects of improving corrosion resistance, improving overall performance, and realizing grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

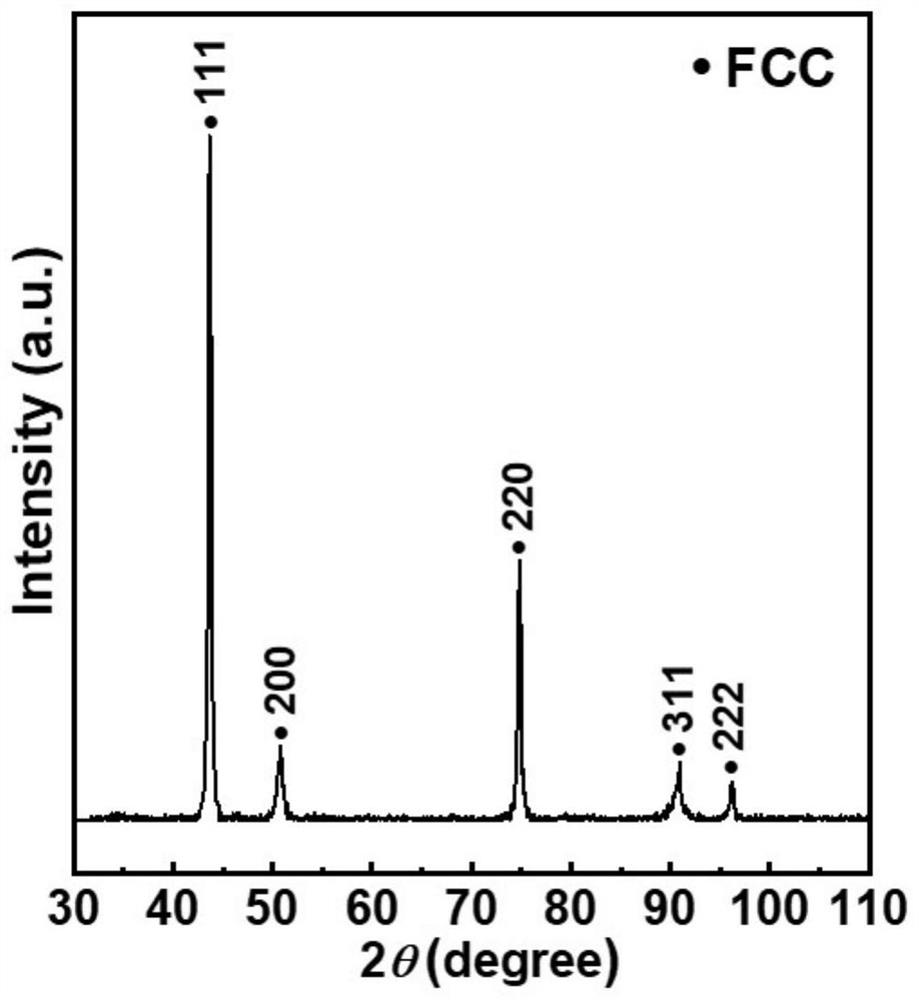

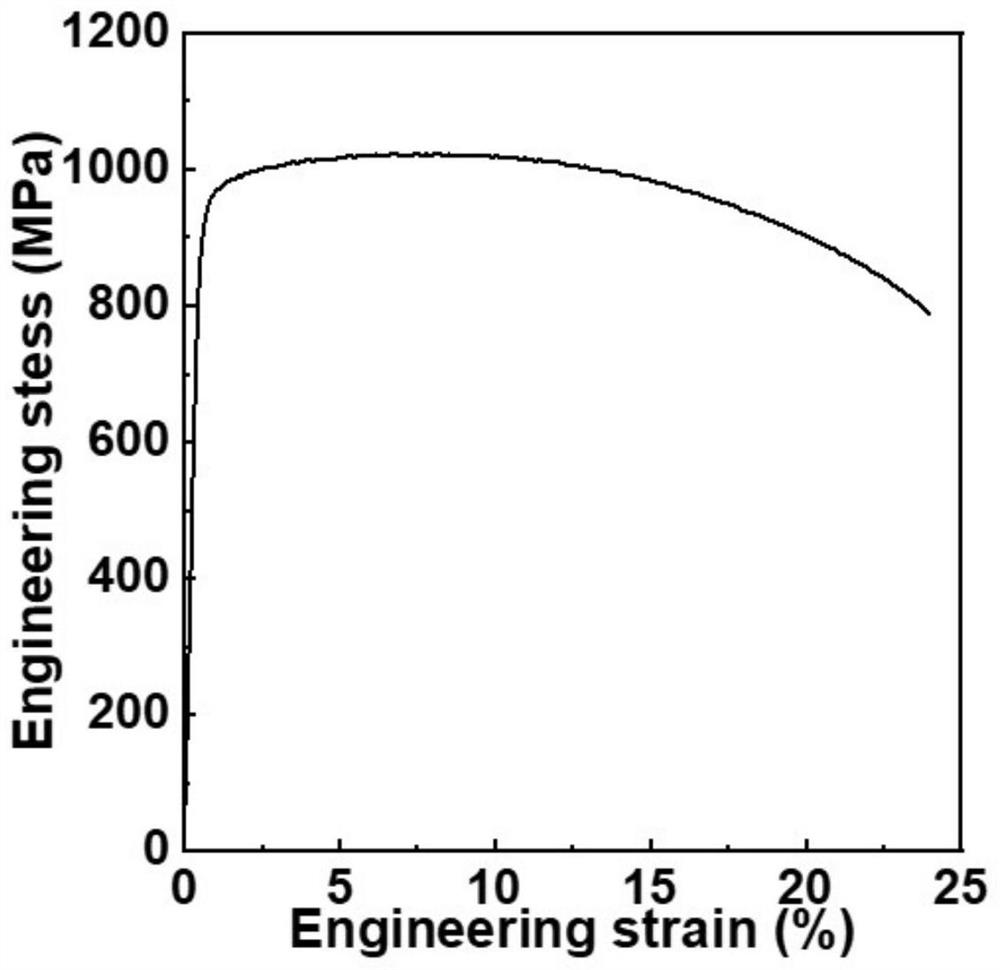

[0054] According to the chemical formula Fe 35 Ni 20 Cr 20 co 20 Ti 1 Al 2.5 Cu 1 Si 0.5 (atomic percentage) is carried out batching, and raw material uses the block body corresponding to each pure element, then smelts under vacuum condition, and smelts repeatedly 4 times. During melting, the vacuum degree is 0.01 Pa, the melting temperature is 1600°C, and the temperature is kept for 10 minutes.

[0055] After obtaining the smelted alloy ingot, the alloy is subjected to multi-pass hot rolling treatment. The hot rolling temperature is 900°C, the single rolling reduction is 10%, and the total rolling reduction is 50%.

[0056] The hot-rolled alloy block is subjected to high-temperature homogenization treatment in an argon protective atmosphere (argon pressure is 10 Pa), the temperature is 1200° C., the homogenization treatment time is 2 hours, and then water quenching.

[0057] The alloy block homogenized at high temperature is subjected to multi-pass room temperature c...

Embodiment 2

[0061] According to the chemical formula Fe 35 Ni 20 Cr 20 co 20 Ti 1 Al 2.5 Cu 1 Si 0.5 (atomic percentage) is carried out batching, and raw material uses the block body corresponding to each pure element, then smelts under vacuum condition, and smelts repeatedly 4 times. During melting, the vacuum degree is 0.01 Pa, the melting temperature is 1600°C, and the temperature is kept for 10 minutes. The smelted alloy ingot is subjected to multi-pass hot rolling treatment, the hot rolling temperature is 1000° C., the single rolling reduction is 10%, and the total rolling reduction is 50%.

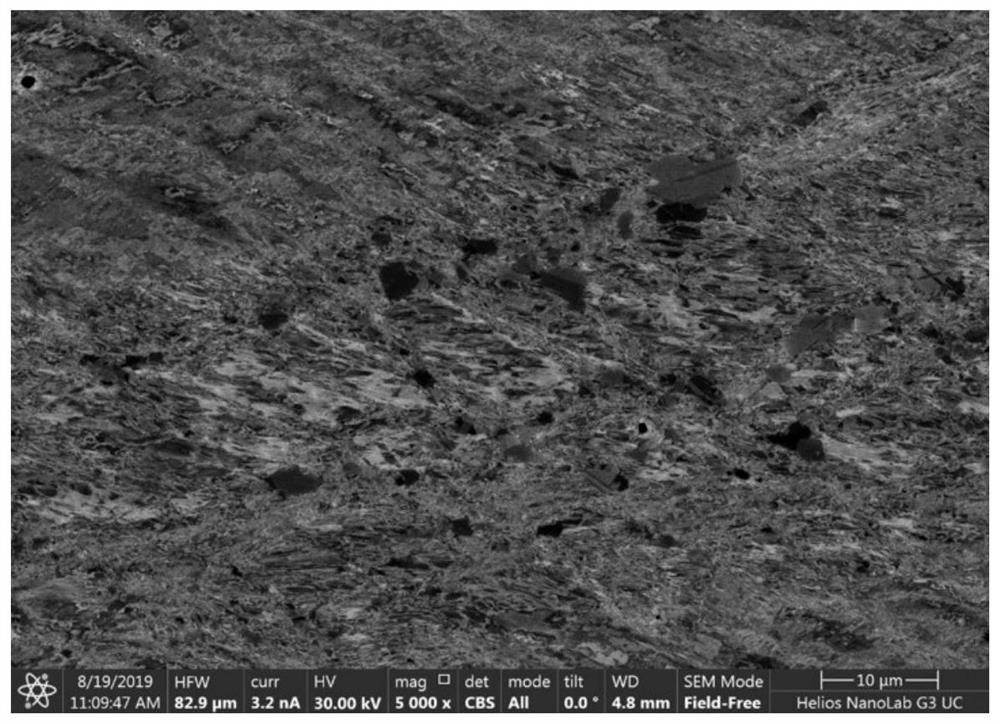

[0062]The hot-rolled alloy block is subjected to high-temperature homogenization treatment in an argon protective atmosphere (argon pressure is about 10Pa), the temperature is 1200°C, the homogenization treatment time is 3 hours, and then water quenched. Depend on Figure 4 It can be seen that after homogenization treatment, the grain size in the face-centered cubic equiaxed grain struc...

Embodiment 3

[0067] Fe-rich alloys Fe 35.1 Ni 20.1 Cr 19.9 co 19.8 Ti 1 Al 2.5 Cu 1 Si 0.5 (atomic percent), melted under vacuum conditions after preparing the material, repeated melting 3 times. During smelting, the vacuum degree is about 0.01 Pa, the melting temperature is about 1700°C, and the temperature is kept for 20 minutes. The smelted alloy ingot is subjected to multi-pass hot rolling treatment, the hot rolling temperature is 950° C., the single rolling reduction is 15%, and the total rolling reduction is 60%.

[0068] The hot-rolled alloy block is subjected to high-temperature homogenization treatment (the pressure of argon gas is about 10 Pa) in an argon protective atmosphere, the temperature is 1200°C, the homogenization treatment time is 4 hours, and then water quenched. The alloy block homogenized at high temperature is subjected to multi-pass room temperature rolling, the single-pass rolling reduction is 15%, and the total rolling reduction is 60%.

[0069] The cold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com