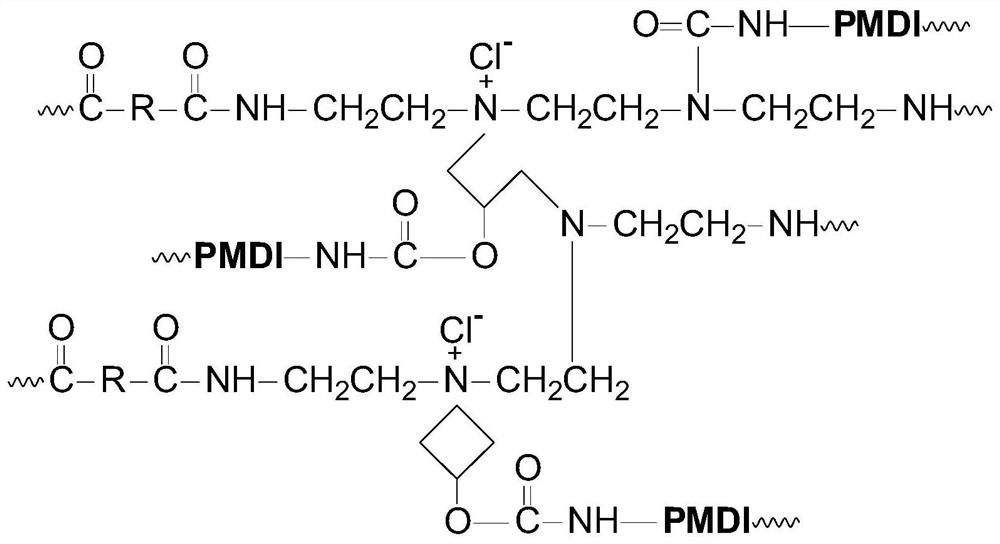

Waterproof polyamide-based adhesive and preparation method thereof

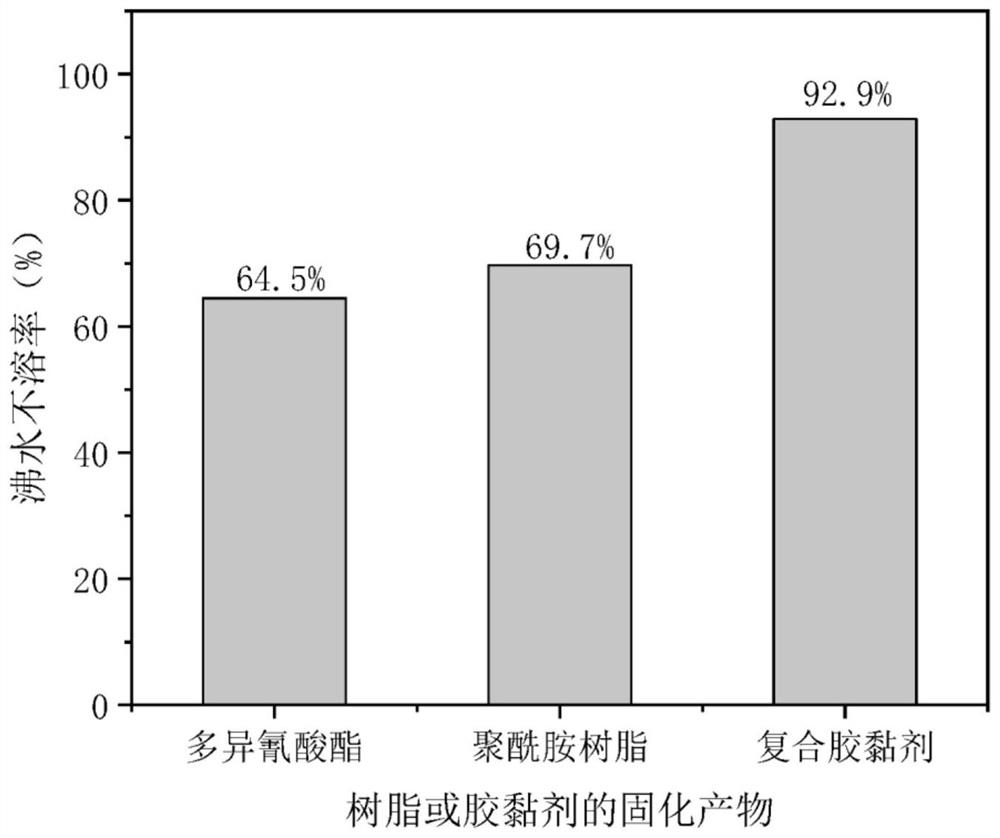

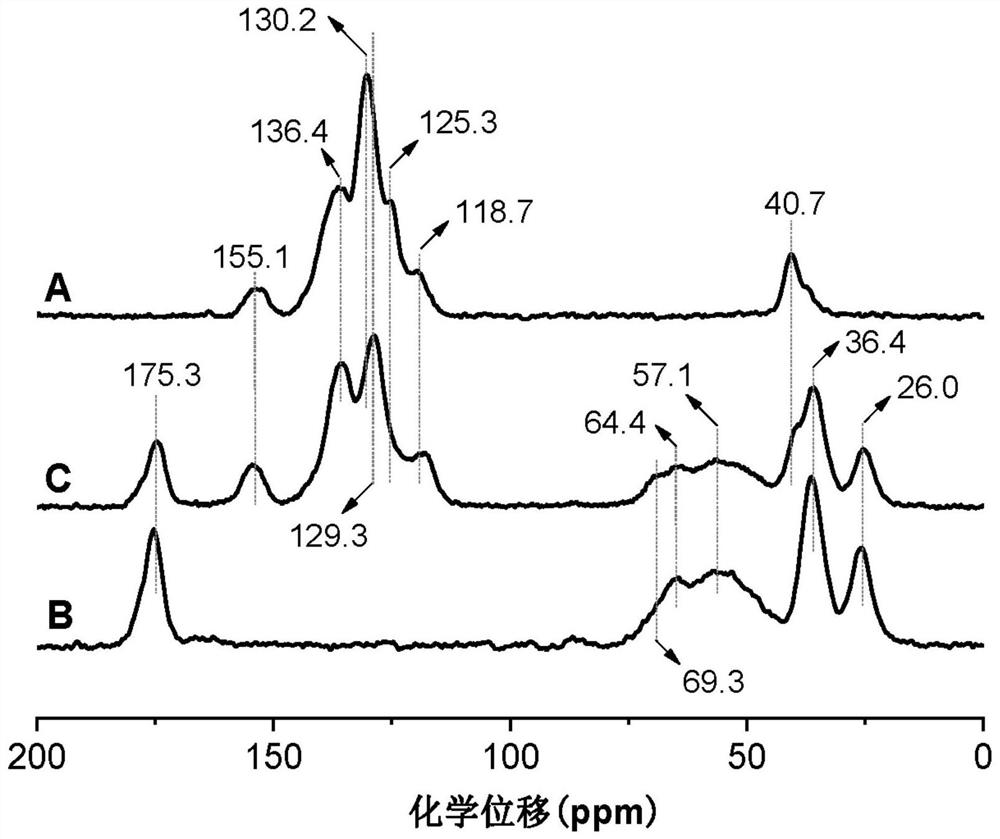

A polyamide-based, adhesive technology, applied in the direction of adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problems of unsatisfactory water resistance and high cost of formaldehyde-free adhesives, and achieve good emulsification and dispersion effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] Embodiment 1: The waterproof grade polyamide-based adhesive of this embodiment consists of 100 parts by weight of polyamide-based water-based cross-linking dispersant, 20-275 parts of water, and 5-45 parts of polymethylene polyphenyl polyisocyanate PMDI And 10 to 185 parts of inorganic fillers, stirred evenly at room temperature.

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the inorganic filler is one of kaolin, talcum powder, calcium carbonate, montmorillonite, bentonite and attapulgite powder with a particle size of 800-5000 mesh Or a mixture composed of any ratio. Others are the same as the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the amount of polymethylene polyphenyl polyisocyanate PMDI is 5% to 20% of the weight of the polyamide-based water-based crosslinking dispersant. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com