High-density wear-resistant PPS plastic and preparation method thereof

A high-density, plastic technology, applied in the field of high-density wear-resistant PPS plastics and its preparation, can solve the problems of increasing the weight and texture of PPS plastics, the product surface is easy to wear, and the plastic wear resistance is poor, and achieves increased affinity and adhesion. The effect of increasing the brittleness, increasing the weight and improving the brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

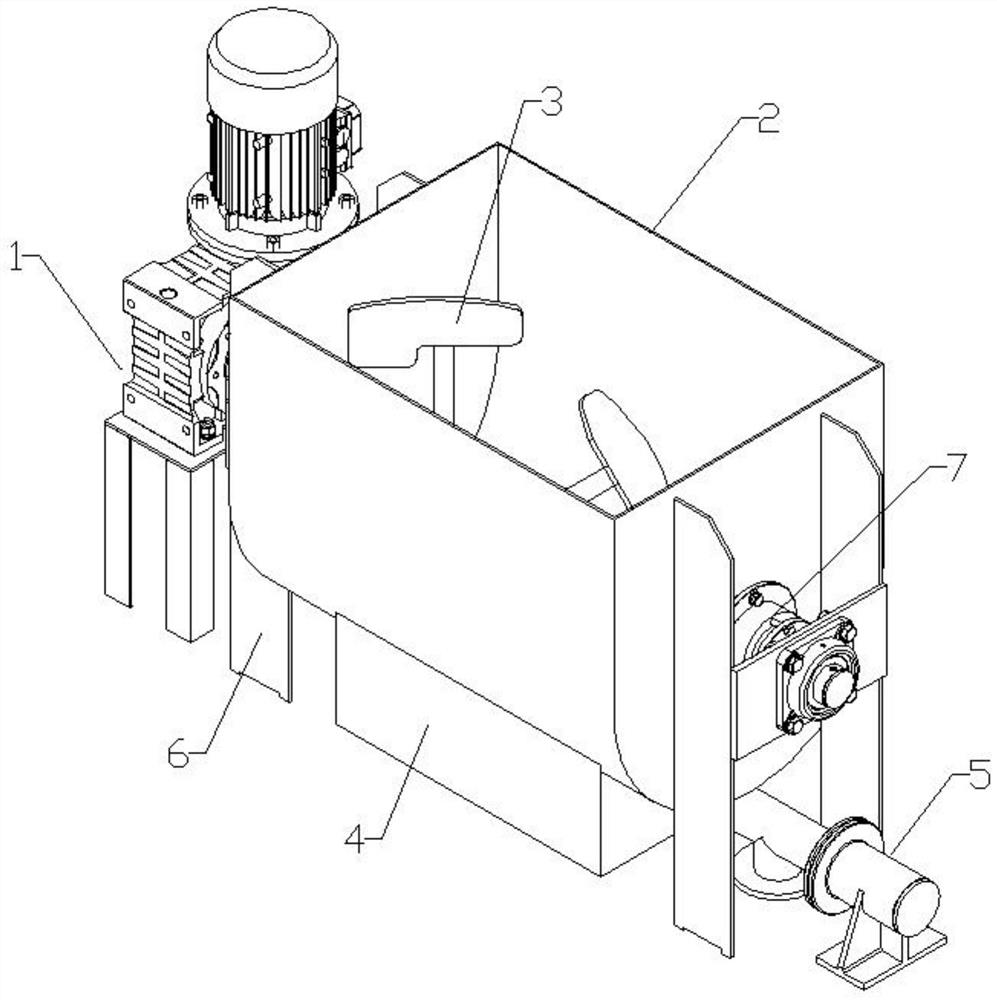

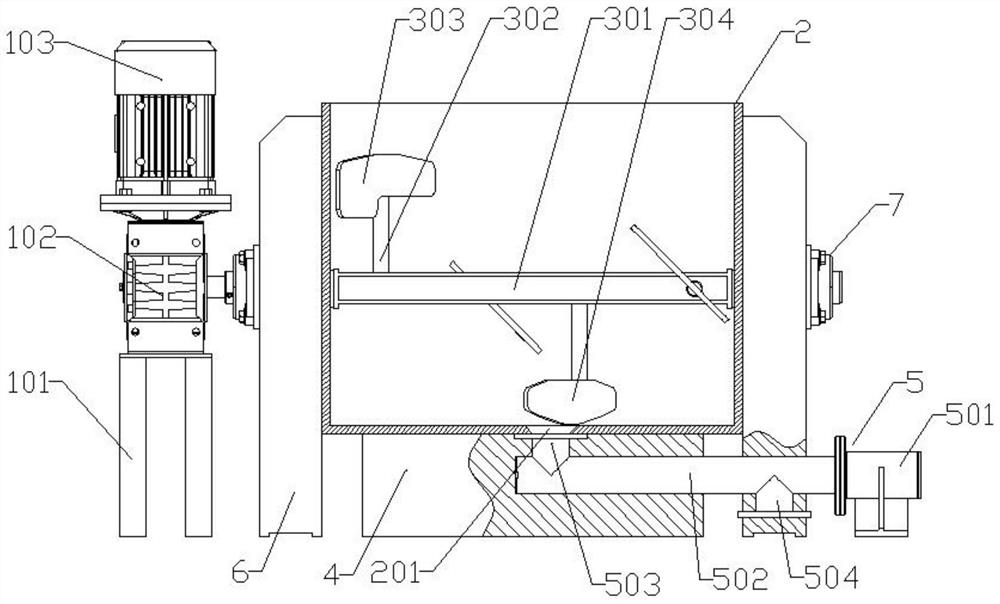

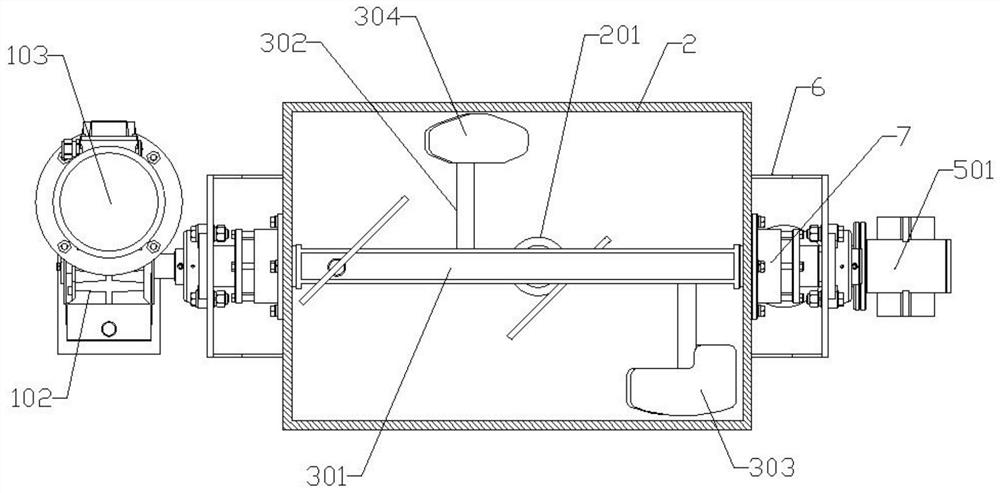

Image

Examples

Embodiment 1

[0037]A high-density wear-resistant PPS plastic, including the following raw materials by weight: 100 parts of polyphenylene sulfide, 30 parts of metal powder, 8 parts of mineral powder composition, 5 parts of toughening agent, 1 part of lubricant, and 10 parts of coupling agent ;

[0038]This kind of high-density wear-resistant PPS plastic is prepared by the following steps;

[0039]Step 1. Spray the coupling agent on the surface of the metal powder and mineral powder composition by spraying, and modify the surface of the metal powder and mineral powder composition, and then stir and mix the metal powder and mineral powder composition to obtain a heavy filler;

[0040]Step 2: Add polyphenylene sulfide, toughening agent, and lubricant into the mixing smelting machine according to the weight of the formula, and then adding the heavy filler prepared in step 1 into the mixing smelting machine at a temperature of 290°C and a rotation speed of 60r / Under the condition of min, stir and mix for 40 ...

Embodiment 2

[0049]A high-density wear-resistant PPS plastic, comprising the following parts by weight of raw materials: 100 parts of polyphenylene sulfide, 32 parts of metal powder, 9 parts of mineral powder composition, 8 parts of toughening agent, 2 parts of lubricant, and 13 parts of coupling agent ;

[0050]This kind of high-density wear-resistant PPS plastic is prepared by the following steps;

[0051]Step 1. Spray the coupling agent on the surface of the metal powder and mineral powder composition by spraying, and modify the surface of the metal powder and mineral powder composition, and then stir and mix the metal powder and mineral powder composition to obtain a heavy filler;

[0052]Step 2: Add polyphenylene sulfide, toughening agent and lubricant into the mixing smelting machine according to the formula weight parts, and then adding the heavy filler prepared in step 1 into the mixing smelting machine at a temperature of 295°C and a rotation speed of 100r / Under the condition of min, stir and m...

Embodiment 3

[0061]A high-density wear-resistant PPS plastic, including the following parts by weight of raw materials: 100 parts of polyphenylene sulfide, 35 parts of metal powder, 10 parts of mineral powder composition, 10 parts of toughening agent, 3 parts of lubricant, 15 parts of coupling agent ;

[0062]This kind of high-density wear-resistant PPS plastic is prepared by the following steps;

[0063]Step 1. Spray the coupling agent on the surface of the metal powder and mineral powder composition by spraying, and modify the surface of the metal powder and mineral powder composition, and then stir and mix the metal powder and mineral powder composition to obtain a heavy filler;

[0064]Step 2: Add polyphenylene sulfide, toughening agent, and lubricant into the mixing smelting machine according to the weight of the formula, and then adding the heavy filler prepared in step 1 to the mixing smelting machine at a temperature of 300°C and a rotation speed of 120r / Under the condition of min, stir and mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com