Preparation of catechol-derived porous polymer and photocatalytic application of catechol-derived porous polymer loaded with high-spin monatomic iron

A porous polymer, catechol technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, organic chemistry, etc., can solve the difficulty of styrene oxide selectivity At the same time reaching 80%, system pollution, high cost problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A kind of preparation of porous polymer, step is as follows:

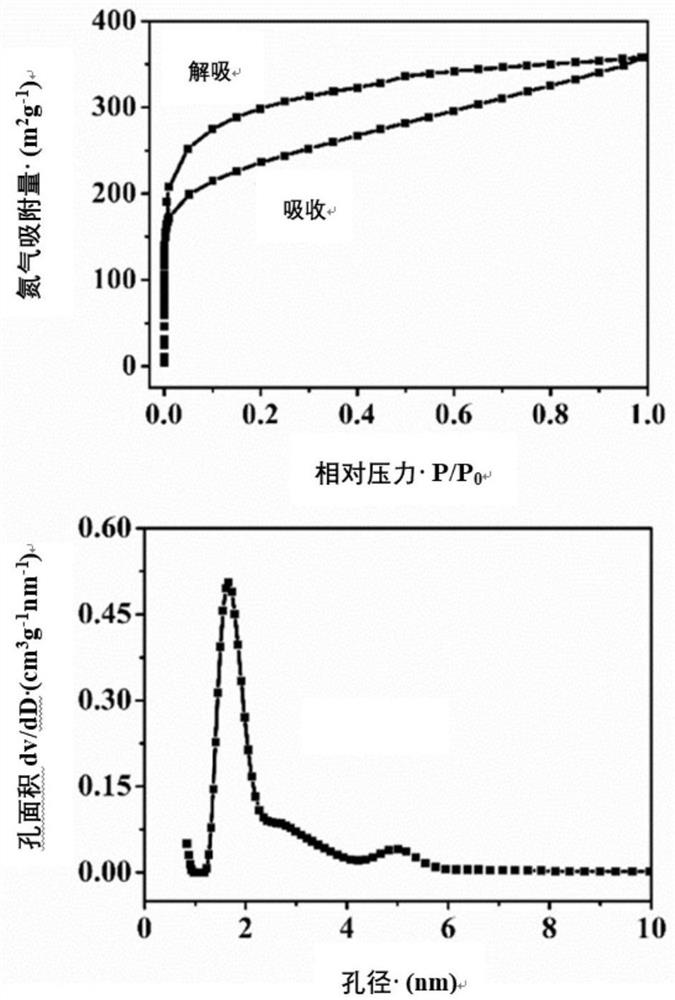

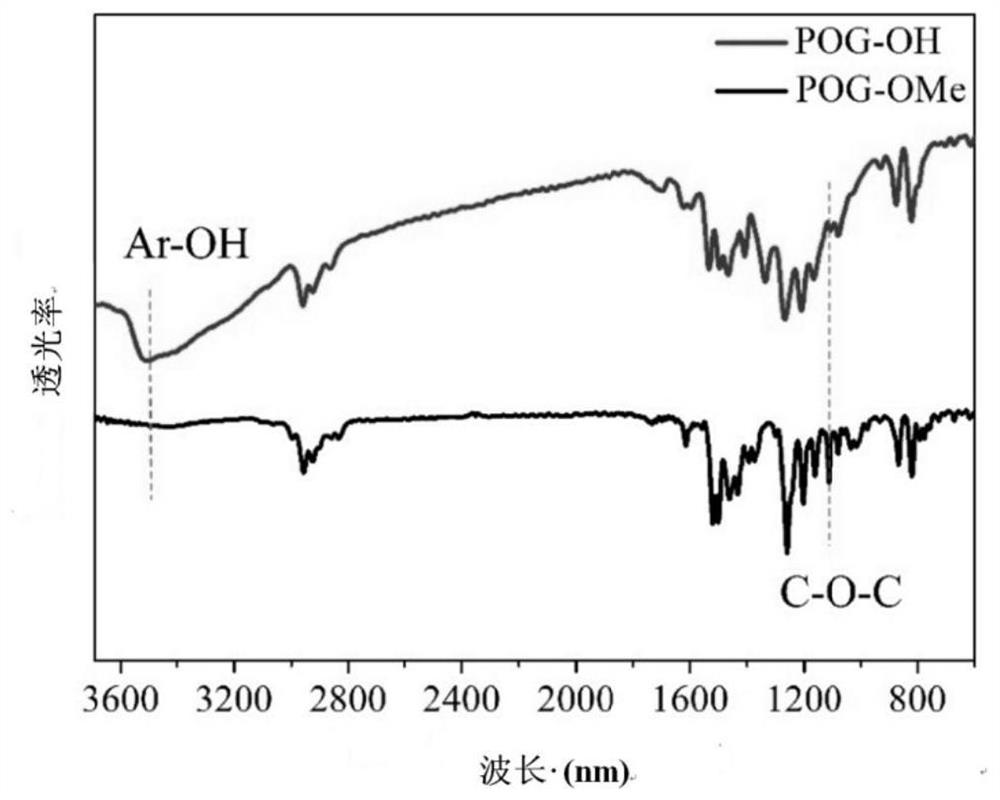

[0075]In 1,3,5-tris(3,4-dimethoxybenzyl)benzene (0.4mmol), 9,9-dimethyl-2,7-fluorenedial (0.6mmol), acetic anhydride (20mmol) Add 100 mL of dichloromethane solvent into the mixed system with ferric chloride (0.08 mmol), and react with magnetic stirring at 25° C. for 48 h. Ferric chloride (72 mmol) was added to the system again, and the reaction was performed under magnetic stirring at 25°C for 12 h under an argon atmosphere. Then add methanol to the system to quench, filter under reduced pressure, and wash the solid residue with water and methanol to obtain the product (POG-OMe) shown in formula 2 with a yield of 91%. BET characterization of POG-OMe (see accompanying drawing figure 1 ), the results show that at lower relative pressure (P / P 0 2 g -1 . Afterwards, carry out infrared characterization and nuclear magnetic characterization to POG-OMe (see accompanying drawing figure 2 ), the infrared char...

Embodiment 2

[0078] A preparation of a catechol-derived porous polymer, the steps are as follows:

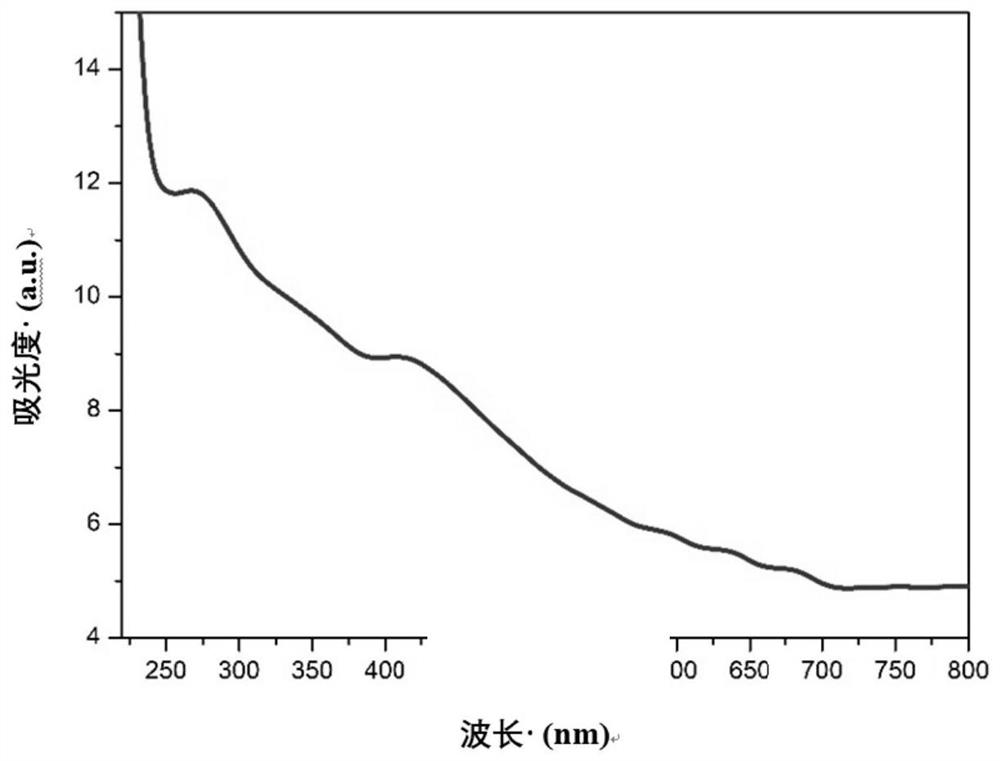

[0079] Weigh 100 mg of POG-OMe and add 200 mL of CH under argon 2 Cl 2 , the reaction system was placed at -20°C, boron tribromide (1 mL) was added, and the reaction system was transferred to an oil bath at 50°C, and stirred by magnetic force for 48 hours. Deionized water was added to quench the reaction, and the solid residue was washed with water and methanol to obtain the product (POG-OH) represented by formula 3 with a yield of 95%. Simultaneously, carry out infrared characterization and NMR characterization to POG-OH (see Figure 4 ), can see 3500cm by infrared test -1 The characteristic peak signal of -OH; at the same time, the C-OH signal peak appears at 150ppm. Then UV test was carried out on POG-OH, the result is shown in the attached picture image 3 shown.

[0080]

Embodiment 3

[0082] A kind of preparation that contains the porous polymer derived from azacyclic pyrocatechol, the steps are as follows:

[0083] In 1,3,5-tris(3,4-dimethoxybenzyl)benzene (0.4mmol), 9H-carbazole-2,7-dialdehyde (0.6mmol), acetic anhydride (20mmol) and trichloride 100 mL of dichloromethane solvent was added to the iron (0.08 mmol) mixed system, and the reaction was performed under magnetic stirring at 25° C. for 48 h. Ferric chloride (72 mmol) was added to the system again, and the reaction was performed under magnetic stirring at 25°C for 12 h under an argon atmosphere. Then add methanol to the system to quench, filter under reduced pressure, and wash the solid residue with water and methanol to obtain the product (as shown in formula 4). Through the BET test of the product, the BET surface area of the product shown in formula 4 can be calculated as high as 893m 2 g -1 .

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com