High-temperature-resistant SiO2-Gd2O3 composite aerogel and preparation method thereof

A composite aerogel, high temperature resistant technology, applied in the preparation/processing of rare earth metal compounds, chemical instruments and methods, silicon compounds, etc., can solve the problems of not exceeding 650 ℃, difficulty in forming rare earth oxide aerogels, etc. Achieve uniform distribution, shorten the preparation cycle, and overcome molding difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

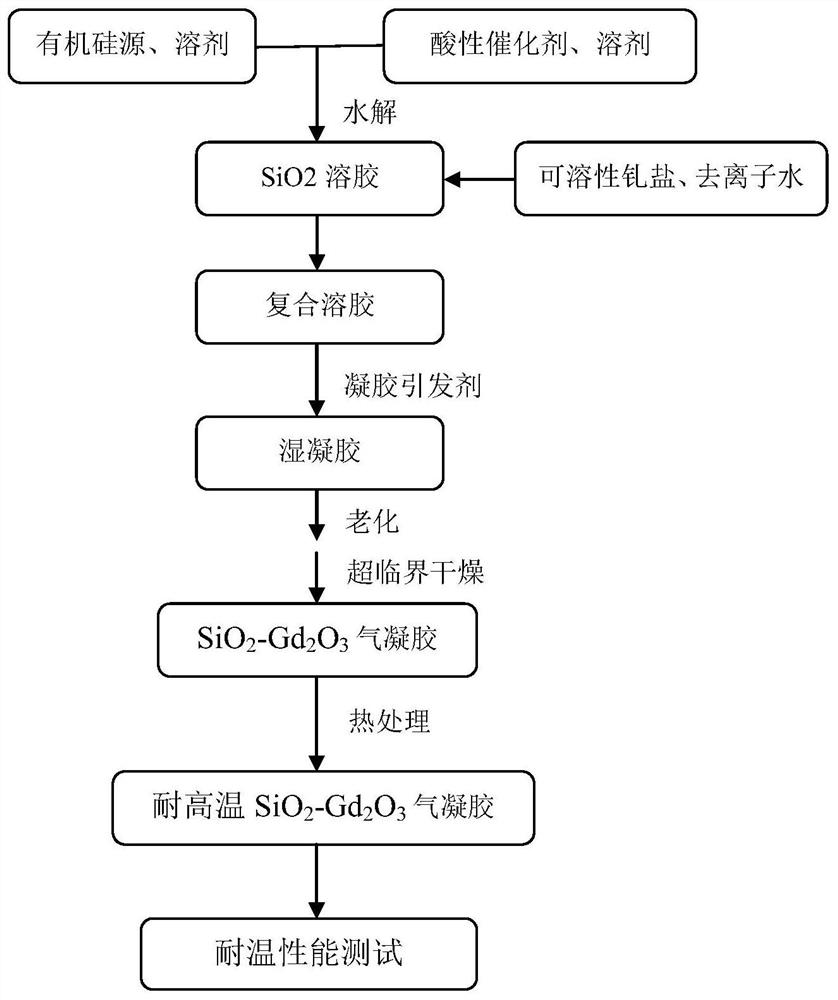

Method used

Image

Examples

Embodiment 1

[0045] High temperature resistant SiO 2 -Gd 2 o 3 The preparation method of composite airgel comprises the following steps:

[0046] 1) Add ethyl orthosilicate and ethanol into the reaction kettle at a molar ratio of 1:2.5, stir at 5°C, and stir at a stirring rate of 350r / min for 15min;

[0047] 2) Mix concentrated nitric acid and ethanol evenly in a ratio of 1:1500;

[0048] 3) Add the solution obtained in step 2) to the solution obtained in step 1) by spraying, keep the temperature in the kettle at 5°C and stir for 10min at a speed of 500r / min, and control the pH value of the material in the reactor to 1.2 , to obtain clarified SiO 2 Sol solution, let stand for 4h;

[0049] 4) Using deionized water to sonicate hydrated gadolinium nitrate until it is completely dissolved, the added amount of hydrated gadolinium nitrate is 10.0wt% of the total mass of the precursor salt, and the molar ratio of deionized water to gadolinium nitrate is 1:100;

[0050] 5) Add the solution o...

Embodiment 2

[0059] High temperature resistant SiO 2 -Gd 2 o 3 The preparation method of composite airgel comprises the following steps:

[0060] 1) Add ethyl orthosilicate and ethanol into the reaction kettle at a molar ratio of 1:6, stir at 10°C, and stir at a rate of 300r / min for 20min;

[0061] 2) Mix glacial acetic acid and ethanol evenly in a ratio of 1:500;

[0062] 3) Add the solution obtained in step 2) to the solution obtained in step 1) by spraying, keep the temperature in the kettle at 10°C and stir for 30min at a speed of 1000r / min, and control the pH value of the material in the reactor to 2.5 , to obtain clarified SiO 2 Sol solution, let stand for 6h;

[0063] 4) Using deionized water to sonicate hydrated gadolinium nitrate until it is completely dissolved, the added amount of hydrated gadolinium nitrate is 5wt% of the total mass of the precursor salt, and the molar ratio of deionized water to gadolinium nitrate is 1:40;

[0064] 5) Add the solution obtained in step 4)...

Embodiment 3

[0073] High temperature resistant SiO 2 -Gd 2 o 3 The preparation method of composite airgel comprises the following steps:

[0074] 1) Add tetraethyl orthosilicate and acetone in a molar ratio of 1:1 into the reaction kettle, stir at 2°C, and stir at a stirring rate of 200r / min for 10min;

[0075] 2) Mix concentrated hydrochloric acid and ethanol evenly in a ratio of 1:3000;

[0076] 3) Add the solution obtained in step 2) to the solution obtained in step 1) by spraying, keep the temperature in the kettle at 2°C and stir for 20min at a speed of 800r / min, and control the pH value of the material in the reactor to 2.0 , to obtain clarified SiO 2 Sol solution, let stand for 4h;

[0077] 4) Using deionized water to sonicate the hydrated gadolinium sulfate until it is completely dissolved, the added amount of the hydrated gadolinium sulfate is 25wt% of the total mass of the precursor salt, and the molar ratio of deionized water to gadolinium sulfate is 1:80;

[0078] 5) Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com