Super-large-section aluminum alloy profile, manufacturing method thereof and application

An aluminum alloy profile and manufacturing method technology, applied in the field of hot extrusion manufacturing, can solve the problems of affecting the weight of the car body, large welding workload, etc., and achieve the effects of increasing the strengthening effect, reducing the production cost and improving the anti-fatigue performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

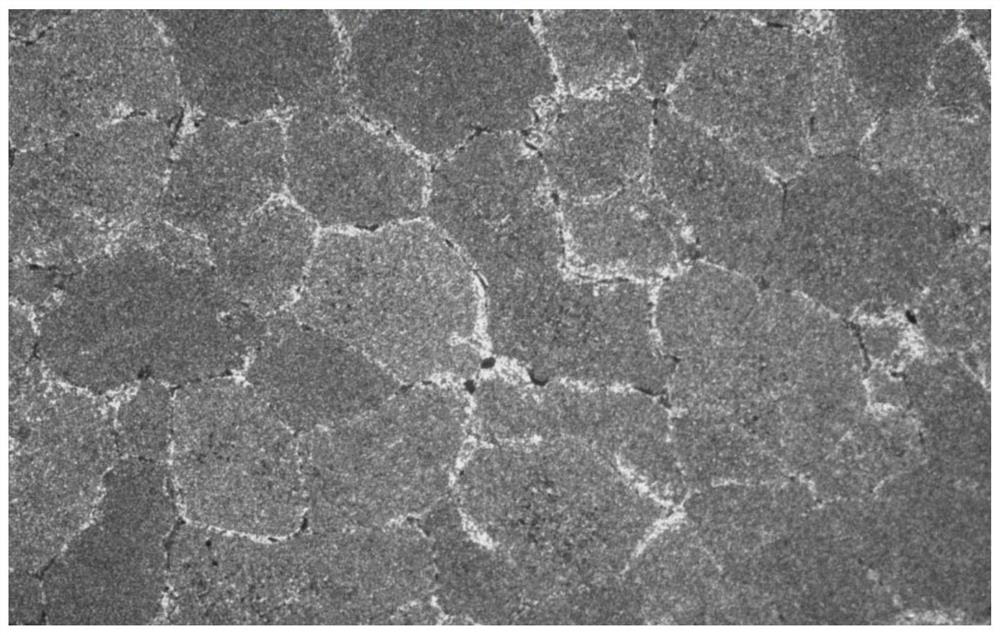

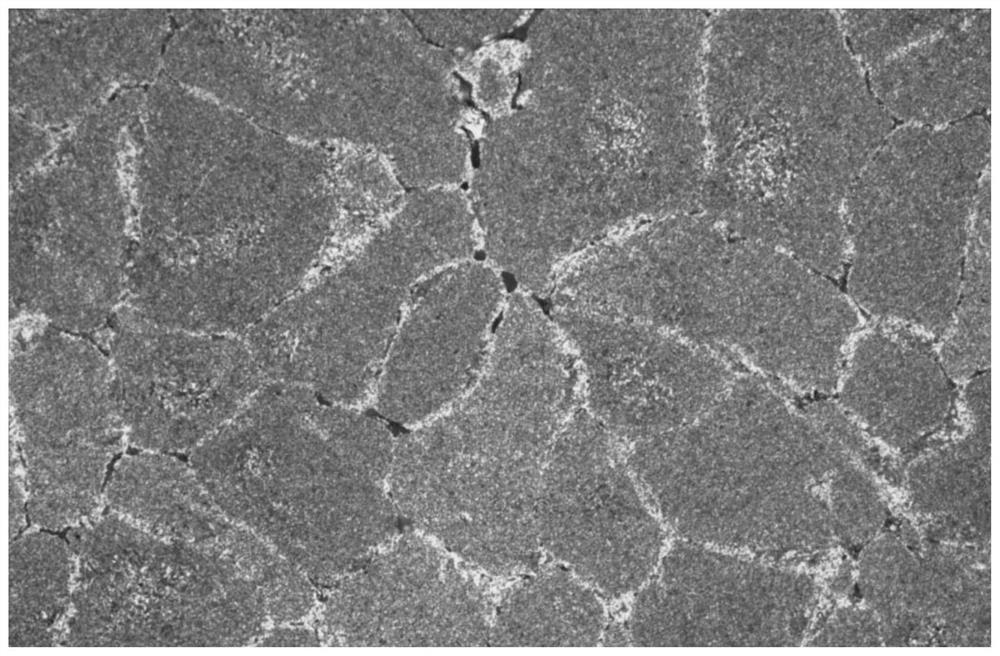

Image

Examples

Embodiment 1

[0041] A super large section aluminum alloy profile, the aluminum alloy profile is composed of the following components by weight:

[0042] Si: 0.5%, Fe: 0.15%, Cu: 0.01%, Mn: 0.02%, Mg: 0.60%, Cr: 0.01%, Zn: 0.01%, Ti: 0.02%, Pb: 0.005%, the balance is Al and Inevitable impurities, of which Mn+Cr: ≤0.50%;

[0043] The manufacturing method of the aluminum alloy profile comprises the following steps:

[0044] (1) Casting: smelting according to the proportion, and cast into a round cast rod with a diameter of 655mm;

[0045] (2) Two-stage homogenization treatment: The round cast rod is subjected to a two-stage homogenization treatment. Insulated for 10h; finally heated to 560°C for 10h; then naturally lowered to room temperature to obtain a homogenized round cast rod;

[0046] Perform 100% ultrasonic flaw detection on round cast rods, and the ultrasonic inspection acceptance level of said round cast rods should meet the requirements of Grade B in GB / T 6519;

[0047] (3) Wago...

Embodiment 2

[0056] A super large section aluminum alloy profile, the aluminum alloy profile is composed of the following components by weight:

[0057] Si: 0.7%, Fe: 0.20%, Cu: 0.10%, Mn: 0.02%, Mg: 0.50%, Cr: 0.20%, Zn: 0.05%, Ti: 0.06%, Pb: 0.001%, the balance is Al and Inevitable impurities, of which Mn+Cr≤0.50%;

[0058] The manufacturing method of the aluminum alloy profile comprises the following steps:

[0059] (1) Casting: smelting according to the proportion, and cast into a round cast rod with a diameter of 465mm;

[0060] (2) Two-stage homogenization treatment: the round cast rod is subjected to a two-stage homogenization treatment. Incubate for 8h; finally heat to 570°C for 8h; then naturally drop to room temperature to obtain a homogenized round cast rod;

[0061] Perform 100% ultrasonic flaw detection on round cast rods, and the ultrasonic inspection acceptance level of said round cast rods should meet the requirements of Grade B in GB / T 6519;

[0062] (3) Wagon: Turn th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com