Low-friction wear-resistant composite material with microfibrillated structure as well as preparation method and application of low-friction wear-resistant composite material

A composite material and low-friction technology, which is applied in the field of low-friction and wear-resistant composite materials and its preparation, can solve the problems of reducing the performance and applicability of friction materials, poor bonding between matrix materials and fillers, and difficulty in reducing friction coefficient and wear. , to achieve the effect of good application prospect, good mechanical strength and excellent wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

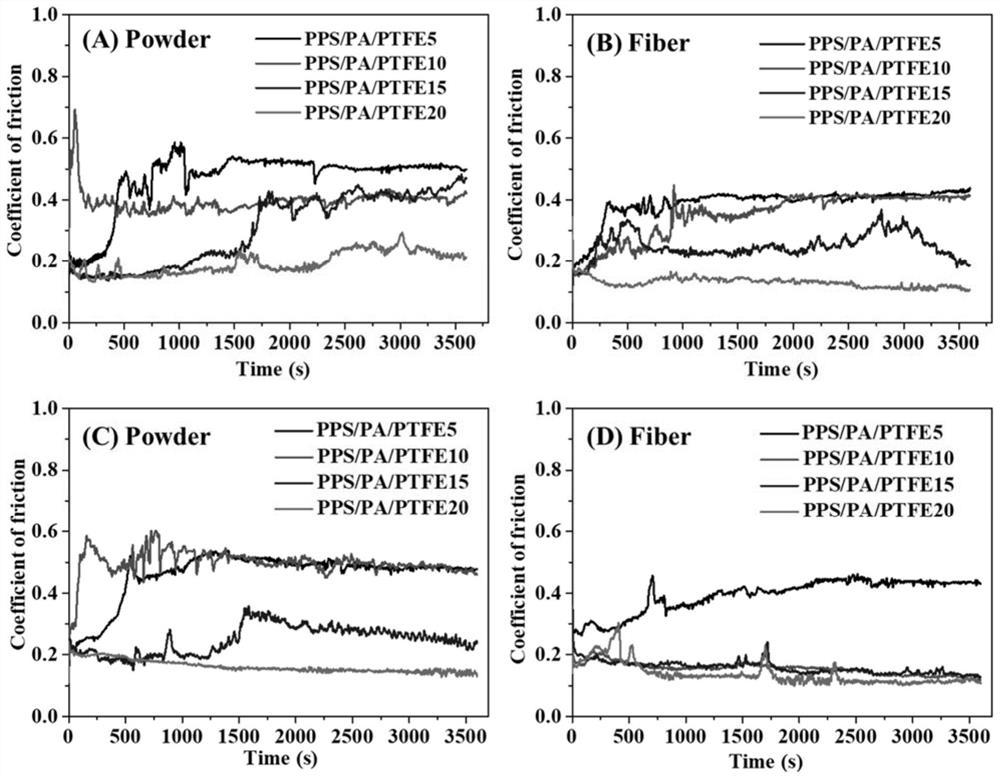

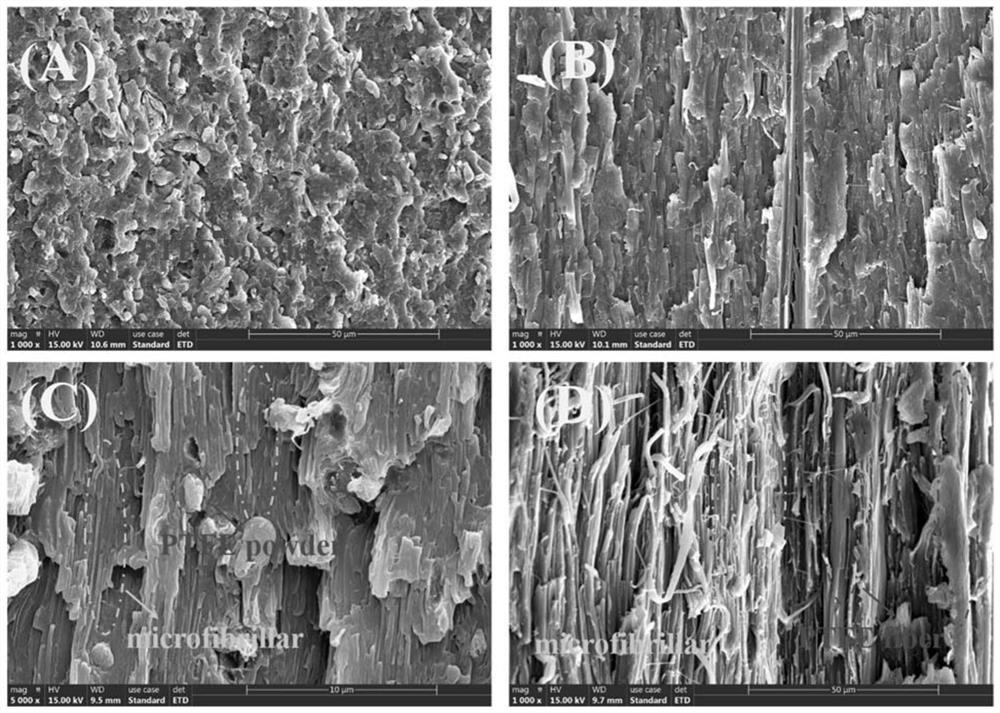

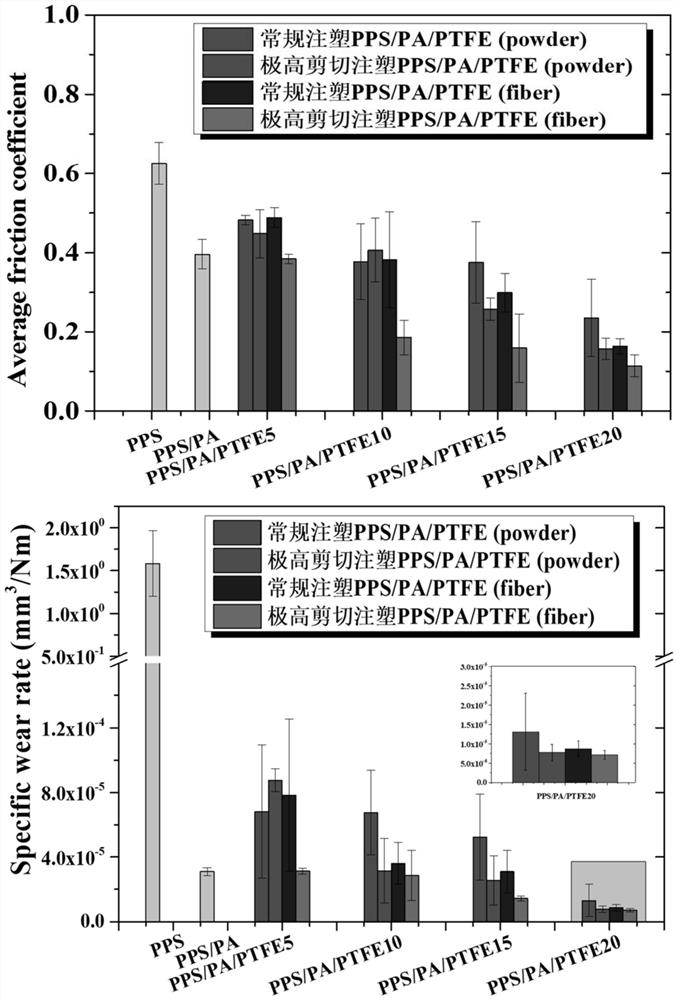

[0062] Embodiment 1, the preparation of the low-friction and wear-resistant composite material of the present invention

[0063] All raw materials were dried in an oven at 80 °C for 12 h before use. Weigh the PPS, PA66 and PTFE powder raw materials according to the mass ratio, and the mass ratio of PPS, PA66 and PTFE powder raw materials is 66.5:28.5:5. The raw materials are mixed by a high-speed mixer (rotating speed 20000r / min). Parallel twin-screw extruder is used for extrusion granulation, the extrusion granulation temperature is 300°C, and the screw speed is 50-80r / min to obtain masterbatch, which is dried for use.

[0064] Then prepare low-friction and wear-resistant composite materials by injection molding machine, adopt conventional injection molding, the conditions of conventional injection molding: injection molding temperature is 300 ℃, holding time is 15s, shear rate is 10-10 2 the s -1 . The low-friction and wear-resistant composite material of the present inv...

Embodiment 2

[0065] Embodiment 2, the preparation of the low-friction and wear-resistant composite material of the present invention

[0066] All raw materials were dried in an oven at 80 °C for 12 h before use. Weigh PPS, PA66 and PTFE powder raw materials according to the mass ratio, and the mass ratio of PPS, PA66 and PTFE powder raw materials is 63:27:10. The raw materials are mixed by a high-speed mixer (rotating speed 20000r / min). Parallel twin-screw extruder is used for extrusion granulation, the extrusion granulation temperature is 300°C, and the screw speed is 50-80r / min to obtain masterbatch, which is dried for use.

[0067] Then prepare low-friction and wear-resistant composite materials by injection molding machine, adopt conventional injection molding, the conditions of conventional injection molding: injection molding temperature is 300 ℃, holding time is 15s, shear rate is 10-10 2 the s -1 . The low-friction and wear-resistant composite material of the present invention ...

Embodiment 3

[0068] Embodiment 3, the preparation of the low-friction and wear-resistant composite material of the present invention

[0069] All raw materials were dried in an oven at 80 °C for 12 h before use. Weigh PPS, PA66 and PTFE powder raw materials according to the mass ratio, and the mass ratio of PPS, PA66 and PTFE powder raw materials is 59.5:25.5:15. The raw materials are mixed by a high-speed mixer (rotating speed 20000r / min). Parallel twin-screw extruder is used for extrusion granulation, the extrusion granulation temperature is 300°C, and the screw speed is 50-80r / min to obtain masterbatch, which is dried for use.

[0070] Then prepare low-friction and wear-resistant composite materials by injection molding machine, adopt conventional injection molding, the conditions of conventional injection molding: injection molding temperature is 300 ℃, holding time is 15s, shear rate is 10-10 2 the s -1 . The low-friction and wear-resistant composite material of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com