Graphene/SEBS composite material with high strength and high damping characteristic, and preparation method thereof

A composite material and graphene technology, which is applied in the field of graphene/SEBS composite material with high strength and high damping characteristics and its preparation, can solve the problems of high strength and high damping loss, and achieve enhanced mechanical properties and mechanical properties Excellent, improved energy dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

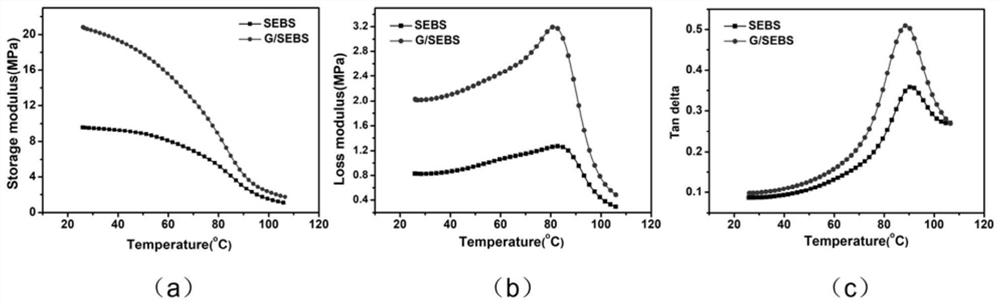

[0033] The preparation method of the graphene / SEBS composite material of described high strength high damping characteristic, comprises the steps:

[0034] 1. Preparation of multiple hydrogen bond molecularly modified graphene

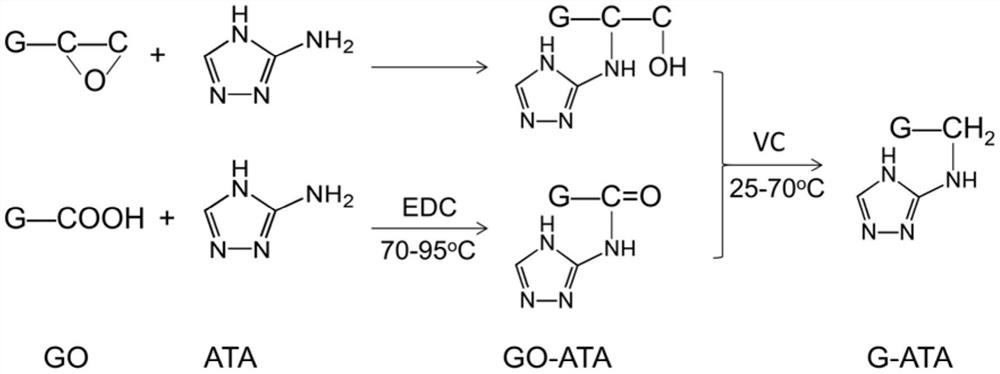

[0035] Using graphene oxide (GO) as a raw material, GO is dispersed in water to prepare a 0.05-3mg / ml aqueous dispersion of GO, and then multiple hydrogen bond molecules and 1-ethyl-(3-dimethylaminopropyl ) carbodiimide hydrochloride (EDC), ultrasonically dispersed for 0.5-1h, stirred at room temperature for 3-8h and stirred in an oil bath at 70-95°C for 1-4h to obtain GO modified by multiple hydrogen bond molecules; then add vitamin C, The mass is 3 to 10 times that of GO. After stirring and reacting at 25 to 70°C for 10 to 24 hours, the product is suction filtered and washed, and dried to obtain graphene modified by multiple hydrogen bond molecules.

[0036] For the sake of illustration, taking the typical triple hydrogen bond molecule 3-amino-1,2,4...

Embodiment 1

[0054] In the present embodiment, the preparation method of the graphene / SEBS composite material of high strength and high damping characteristic is as follows:

[0055] 1. Take GO prepared by electrolytic graphite oxide method, and prepare 100mL of GO / water dispersion with a concentration of 2mg / ml. The atomic ratio of oxygen in GO is 36%, and the GO sheet contains carboxyl, epoxy, hydroxyl and carbonyl functional groups , the diameter of the sheet is 100nm-3μm, and the number of sheets is a single layer. Weigh 2g of EDC and 0.3g of ATA and add them to the aqueous dispersion of GO, and disperse them by ultrasonic for 0.5h. The ultrasonic dispersion was placed in an Erlenmeyer flask, stirred and reacted under a constant temperature digital display magnetic stirrer, first stirred at room temperature for 6 hours, and then stirred and reacted in an oil bath at 90° C. for 2.5 hours.

[0056] 2. After the reaction is over, add 1 g of vitamin C to the above reaction solution, contin...

Embodiment 2

[0063] In the present embodiment, the preparation method of the graphene / SEBS composite material of high strength and high damping characteristic is as follows:

[0064] 1. Take the GO prepared by the Hummers chemical oxidation method and prepare 100 mL of GO / water dispersion with a concentration of 1 mg / ml. The atomic ratio of oxygen in GO is 45%, and the GO sheet contains carboxyl, epoxy, hydroxyl, and carbonyl functional groups , the diameter of the sheet is 1 μm to 5 μm, and the number of sheets is a single layer. Weigh 1 g of EDC and 0.3 g of ATA and add them to the aqueous dispersion of GO, and ultrasonically disperse for 0.5 h. The ultrasonic dispersion was placed in an Erlenmeyer flask, stirred and reacted under a constant temperature digital display magnetic stirrer, first stirred at room temperature for 6 hours, and then stirred and reacted in an oil bath at 85° C. for 3 hours.

[0065] 2. After the reaction is over, add 0.5g vitamin C to the above reaction solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet diameter | aaaaa | aaaaa |

| Sheet diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com