Yttrium-based metal-organic framework material and application thereof

An organic framework and metal-based technology, applied in the field of porous metal-organic framework materials, can solve the problems of missing the best treatment opportunity and inability to evaluate treatment methods affected by diseased tissues, and achieve the effects of reducing treatment costs, mild conditions, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

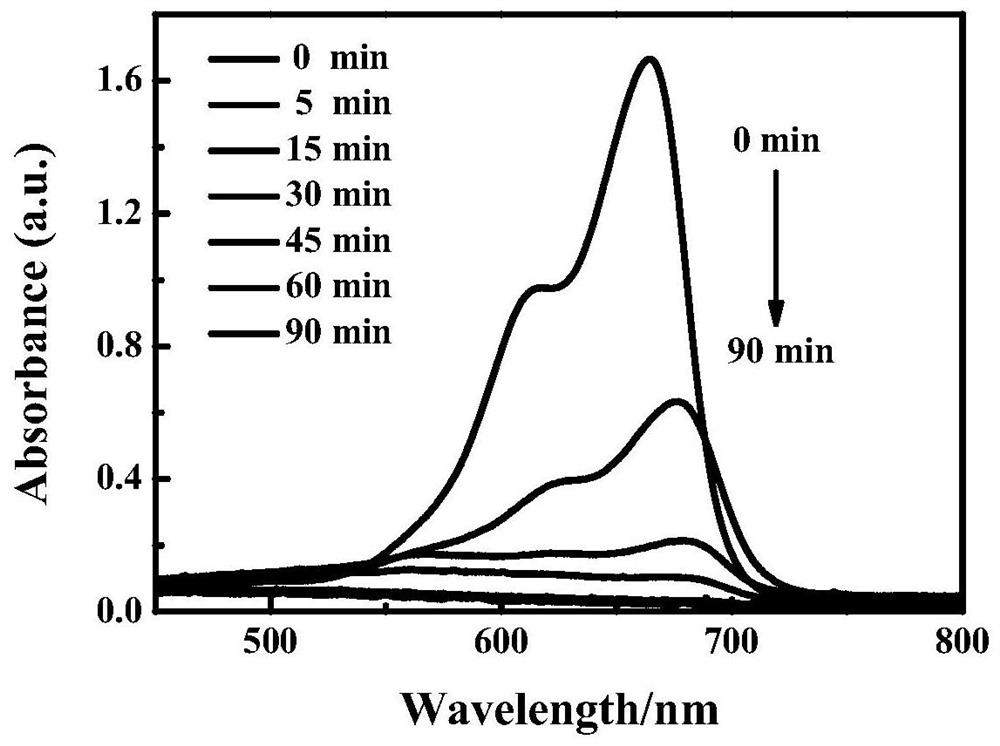

Image

Examples

preparation example Construction

[0026] In a second aspect, the present invention provides a method for preparing yttrium-based metal-organic framework (Y-MOF), comprising the following steps:

[0027] (1) provide respectively the aqueous solution of trivalent yttrium ion and the organic ligand solution containing organic ligand L and o-fluorobenzoic acid;

[0028] (2) Mix the aqueous solution of trivalent yttrium ions in step (1) and the organic ligand solution containing organic ligand L and o-fluorobenzoic acid, and then react in airtight conditions at 100-120°C for 2-3 days, After cooling, solid-liquid separation, organic solvent washing and drying, the yttrium-based metal-organic framework (Y-MOF) is finally obtained.

[0029] Wherein, the organic ligand L is 2,4,6-tris(4-carboxyphenyl)-1,3,5-triazine, 2,4,6-tris(4-pyridine)1,3,5 - Triazine or pyridine 1,3,5-tribenzoate.

Embodiment 1

[0032] (1) 22mg of yttrium nitrate Y (NO 3 ) 3 Dissolve in 1.8mL of aqueous solution to make Y(NO 3 ) 3 Aqueous solution; 24 mg of 2,4,6-tris(4-carboxyphenyl)-1,3,5-triazine and 346.2 mg of o-fluorobenzoic acid were dissolved in 12 mL of N,N-dimethylformamide , to prepare an organic ligand solution with a molar concentration of 0.0042 mol / L of 2,4,6-tris(4-carboxyphenyl)-1,3,5-triazine and a molar concentration of 0.201 mol / L of o-fluorobenzoic acid .

[0033] (2) The above 1.8mL Y(NO 3 ) 3 The aqueous solution and 12mL of organic ligand solution were placed in a reaction kettle, ultrasonicated at an ultrasonic frequency of 25KHz for 8min, then placed at 105°C for 48h, cooled to room temperature, filtered, and treated with N,N-dimethylformamide The solid particles obtained after filtration are washed and dried to obtain yttrium-based metal-organic framework material (Y-MOF), whose chemical formula is: Y 4 (C 24 N 3 h 12 o 10.5 ) 2 ·(DMF) 3.5 ·(H 2 O).

Embodiment 2

[0035] (1) 19.8mg of yttrium nitrate Y (NO 3 ) 3 Dissolve in 1.8mL of aqueous solution to prepare Y(NO 3 ) 3 aqueous solution; 21 mg of 2,4,6-tris(4-pyridine) 1,3,5-triazine and 334.8 mg of o-fluorobenzoic acid were dissolved in 12 mL of N,N-dimethylacetamide to form 2,4,6-tris(4-pyridine)1,3,5-triazine molar concentration of 0.004mol / L, o-fluorobenzoic acid molar concentration of 0.200mol / L organic ligand solution.

[0036] (2) The above 1.8mL Y(NO 3 ) 3 The aqueous solution and 12mL organic ligand solution were placed in a reaction kettle, ultrasonicated at an ultrasonic frequency of 30KHz for 7min, then placed at 110°C for 48h, cooled to room temperature, filtered, and treated with N,N-dimethylacetamide The solid particles obtained after filtration are washed and dried to obtain yttrium-based metal-organic framework material (Y-MOF), whose chemical formula is: Y 4 (C 18 N 6 h 9 ) 2 ·(DMF) 3.5 ·(H 2 O).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com