A low-cost titanium-based porous material fabrication process with high energy absorption properties

A technology of porous materials and absorption characteristics, which is applied in the field of low-cost titanium-based porous material preparation technology, can solve the problems of high cost and low strength, and achieve the effect of improving bonding strength, low density, and increasing bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

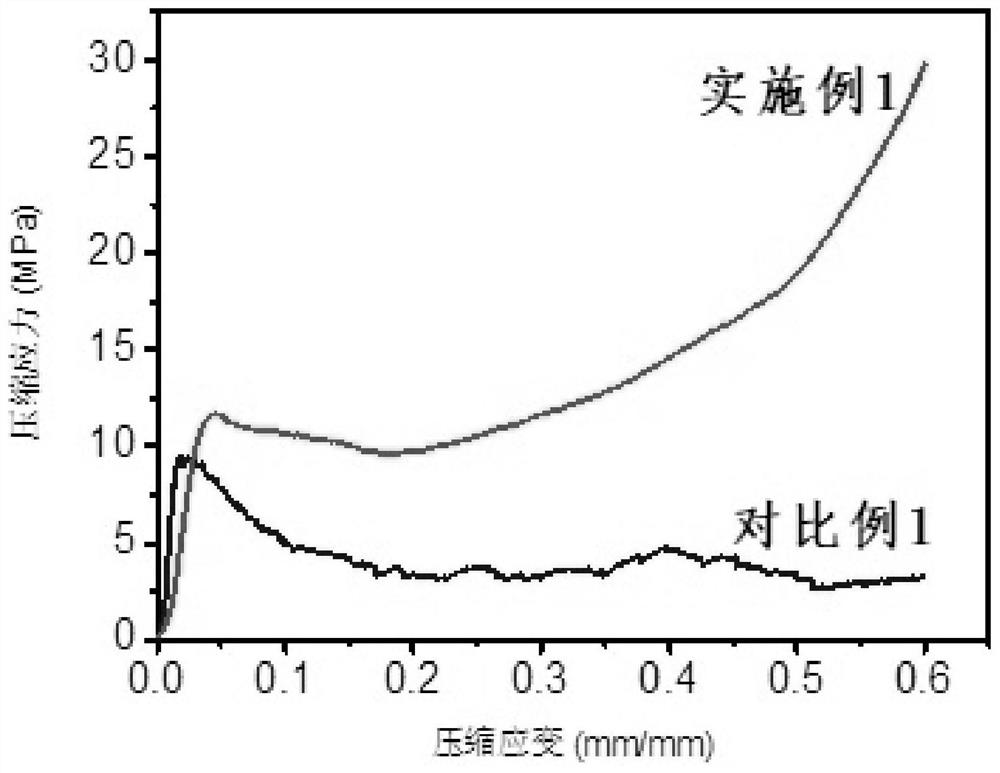

Embodiment 1

[0022] This embodiment includes the following steps:

[0023] Step 1. Pre-compressing the accumulated titanium chips along the thickness direction at room temperature to obtain a titanium-based porous green body; the porosity of the titanium-based porous green body is 80%;

[0024] Step 2. Place the titanium-based porous green body obtained in step 1 in a vacuum furnace at a temperature of 1200° C. and a vacuum degree of 1×10 -2 Under the condition of Pa, heat preservation for 2 hours for high-temperature vacuum sintering, so that the node parts in the titanium-based porous green body are metallurgically bonded, and the titanium-based porous green body is obtained after cooling;

[0025] Step 3, inject 502 glue into the pores of the titanium-based porous body obtained in step 2 at room temperature to fill each node area, and obtain a titanium-based porous material after drying at room temperature; the equivalent pores of the titanium-based porous material The degree is 70%. ...

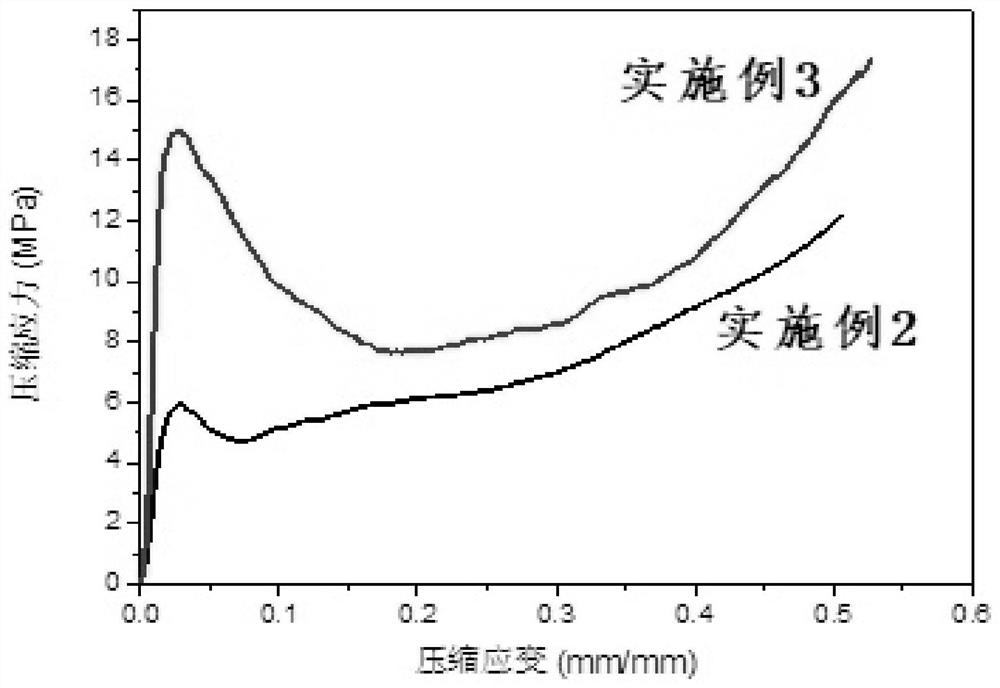

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] Step 1. Pre-compressing the accumulated titanium chips along the thickness direction at room temperature to obtain a titanium-based porous green body; the porosity of the titanium-based porous green body is 87%;

[0037] Step 2. Place the titanium-based porous green body obtained in step 1 in a vacuum furnace at a temperature of 1200° C. and a vacuum degree of 1×10 -2 Under the condition of Pa, heat preservation for 2 hours for high-temperature vacuum sintering, so that the node parts in the titanium-based porous green body are metallurgically bonded, and the titanium-based porous green body is obtained after cooling;

[0038] Step 3, inject 502 glue into the pores of the titanium-based porous body obtained in step 2 at room temperature to fill each node area, and obtain a titanium-based porous material after drying at room temperature; the equivalent pores of the titanium-based porous material The degree is 77%. ...

Embodiment 3

[0042] This embodiment includes the following steps:

[0043] Step 1. Pre-compressing the aggregated titanium chips along the thickness direction at room temperature to obtain a titanium-based porous green body; the porosity of the titanium-based porous green body is 72%;

[0044] Step 2. Place the titanium-based porous green body obtained in step 1 in a vacuum furnace at a temperature of 1200° C. and a vacuum degree of 1×10 -2 Under the condition of Pa, heat preservation for 2 hours for high-temperature vacuum sintering, so that the node parts in the titanium-based porous green body are metallurgically bonded, and the titanium-based porous green body is obtained after cooling;

[0045] Step 3, inject 502 glue into the pores of the titanium-based porous body obtained in step 2 at room temperature to fill each node area, and obtain a titanium-based porous material after drying at room temperature; the equivalent pores of the titanium-based porous material The degree is 64%.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com