Method for preparing high-activity ternary metal sulfide oxygen evolution catalyst from waste copper foils

A ternary metal, high-activity technology, applied in the field of waste resource utilization and catalytic chemistry, can solve the problems of waste of resources, occupation of land resources, harm to the environment, etc., and achieve the effects of simple production process, accelerated reaction rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example is a method of using waste copper foil to prepare a highly active ternary metal sulfide oxygen evolution catalyst, which is carried out in sequence according to the following steps:

[0043] (11) Pretreatment of waste copper foil: wash the cut waste copper foil (waste copper foil is the material stripped from the electrode of waste lithium-ion battery containing copper elements) in sequence with 3M hydrochloric acid, and then use ethylene glycol and acetone to sonicate for 30 minutes respectively , soak the treated waste copper foil in 30mmol manganese chloride solution for later use, and record it as A1;

[0044] (12) Add a certain amount of sodium sulfate solution to A1 until the pH value of the solution is 5 to obtain B1;

[0045] (13) Add 10mL of 0.5mM ferric chloride solution to B1 to obtain C1;

[0046] (14) Copper foil is used as the working electrode, platinum mesh is used as the auxiliary electrode, and an electrolyte containing manganese salt and...

Embodiment 2

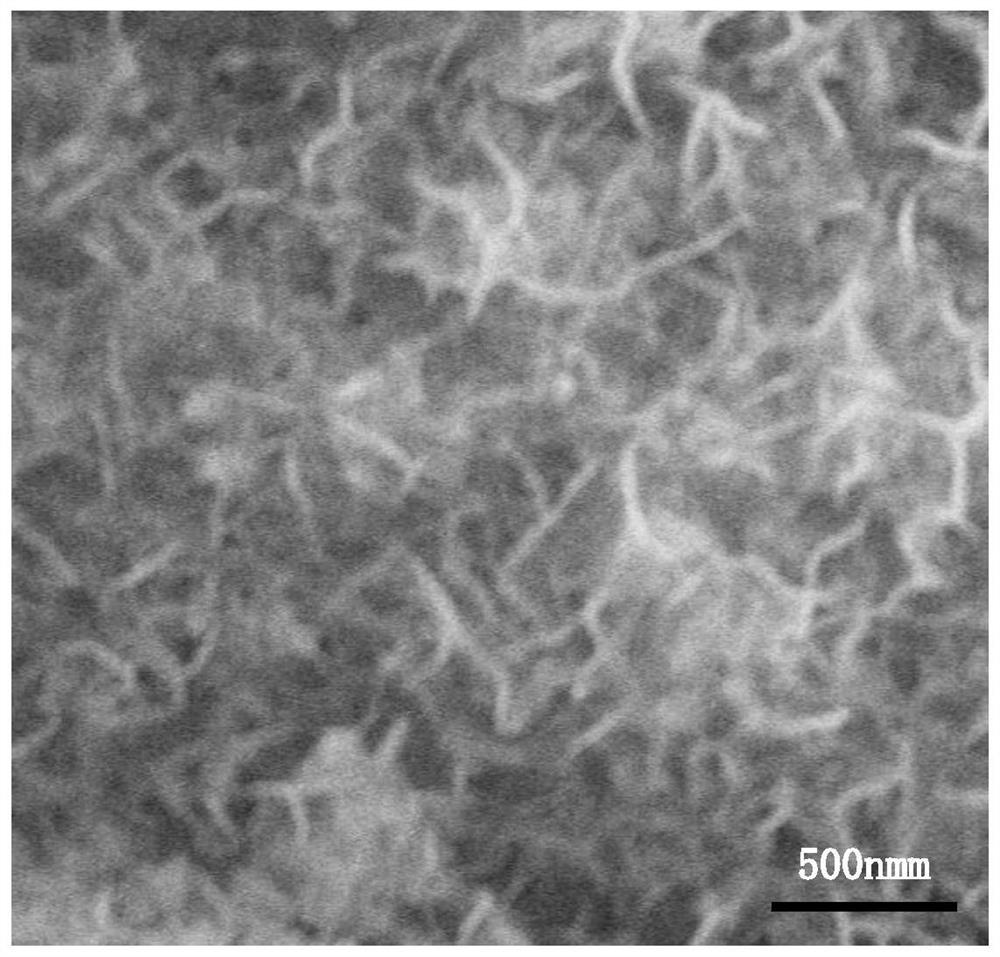

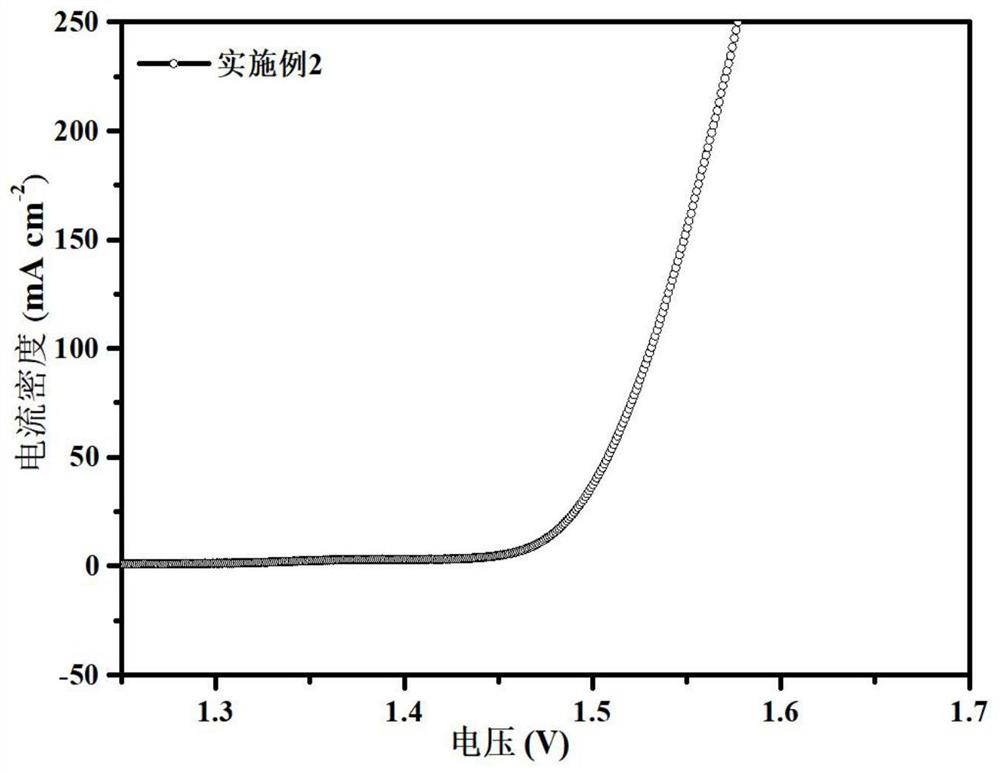

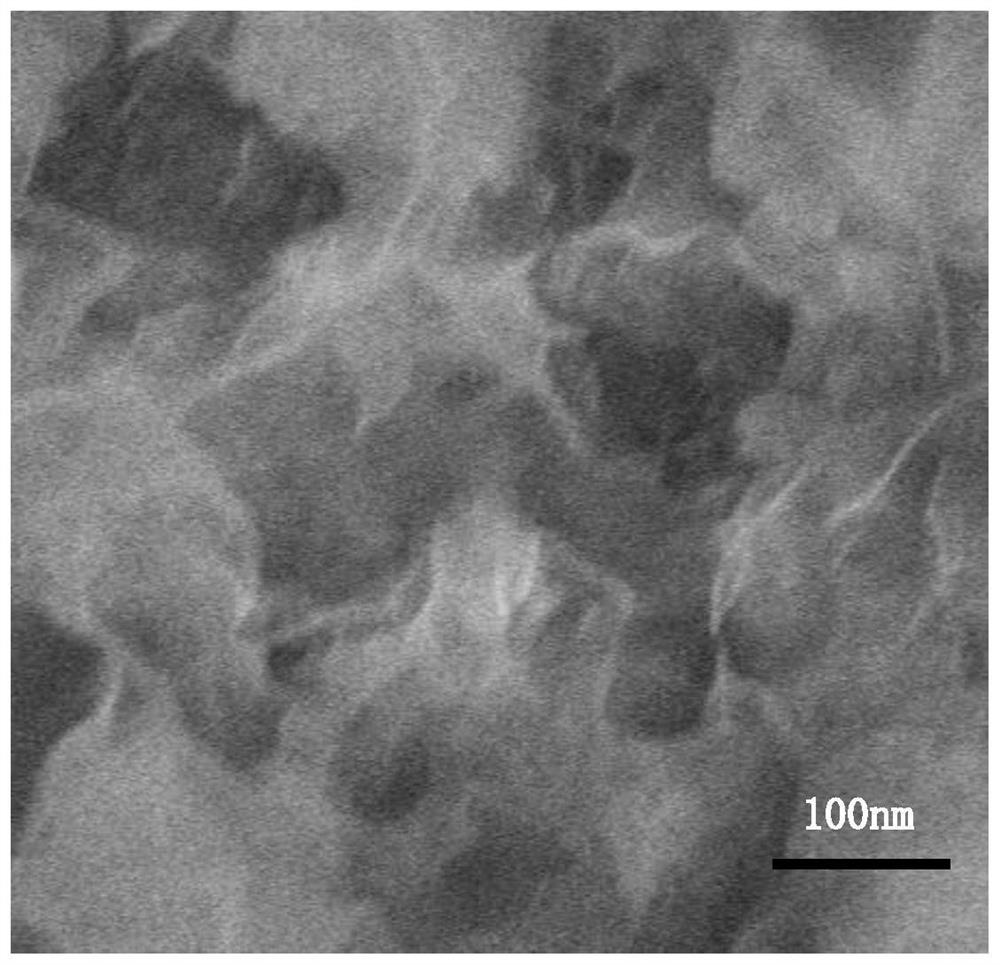

[0050] This example is a method of using waste copper foil to prepare a highly active ternary metal sulfide oxygen evolution catalyst, which is carried out in sequence according to the following steps:

[0051] (21) Pretreatment of waste copper foil: wash the cut waste copper foil (waste copper foil is the material stripped from the electrode of waste lithium-ion battery containing copper elements) in sequence with 3M hydrochloric acid, and then use ethylene glycol and acetone to sonicate for 30 minutes respectively , soak the treated waste copper foil in 50mmol manganese chloride solution for later use, and record it as A1;

[0052] (22) Add a certain amount of sodium sulfate solution to A1 until the pH value of the solution is 5 to obtain B1;

[0053] (23) Add 5mL of 0.8mM ferric chloride solution to B1 to obtain C1;

[0054] (24) Copper foil is used as the working electrode, platinum mesh is used as the auxiliary electrode, and the electrolyte containing manganese salt and...

Embodiment 3

[0058] This example is a method of using waste copper foil to prepare a highly active ternary metal sulfide oxygen evolution catalyst, which is carried out in sequence according to the following steps:

[0059] (31) Pretreatment of waste copper foil: Wash the cut waste copper foil (waste copper foil is the material stripped from the electrode of the waste lithium-ion battery containing copper elements) in sequence with 3M hydrochloric acid, and then use ethylene glycol and acetone to sonicate for 30 minutes , soak the treated waste copper foil in 40mmol manganese chloride solution for later use, and record it as A1;

[0060] (32) Add a certain amount of sodium sulfate solution to A1 until the pH value of the solution is 5 to obtain B1;

[0061] (33) Add 8 mL of 0.6 mM ferric chloride solution to B1 to obtain C1;

[0062] (34) Copper foil is used as the working electrode, platinum mesh is used as the auxiliary electrode, and the electrolyte containing manganese salt and iron s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com