Alkali-free high-aluminium borosilicate glass and preparation method thereof

A silicate glass, high alumina boron technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve problems such as high environmental damage, reduce the probability of glass breakage, improve product quality and stabilize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] According to a preferred embodiment of the present invention, the sag of the glass is 39-55mm.

[0028] According to a preferred embodiment of the present invention, the glass dust is 1-2 per square centimeter.

[0029] According to a preferred embodiment of the present invention, the glass density of the glass is 2.3-2.45g / cm 3 Or Young's modulus 68-71 (GPa); expansion coefficient at 10-7°C is 36-38; and / or glass stress 50-120PSI, preferably 60-80PSI, glass dust is 1-2 / square centimeter .

[0030] According to the present invention, the optional range of the clarifier is relatively wide, such as SnO 2 , SnO, Sb 2 o 3 and CeO 2 one or more of.

[0031] The glass of the present invention has lower flexibility, higher rigidity, and higher Young's modulus.

[0032] The invention prepares the glass substrate with the above-mentioned composition and physical and chemical properties for the first time, which is of great significance to the improvement and stability of ...

Embodiment 1

[0058] (1) Prepare glass substrate raw materials according to the following weight percentages, 58% by weight of silicon oxide, 9% by weight of boron oxide, 14% by weight of aluminum oxide, 6% by weight of barium oxide, 7.5% by weight of calcium oxide, 5% by weight Strontium oxide, 0.1 wt% zinc oxide, 0.1 wt% magnesium oxide, 0.1 wt% zirconia, 0.1 wt% clarifying agent SnO 2 .

[0059] (2) The glass raw material is melted into glass liquid, clarified to remove impurities, and then solidified, shaped, and annealed to become a solid glass plate, and then draw lines on the glass plate with a knife, and then break the glass plate at the line drawn broken.

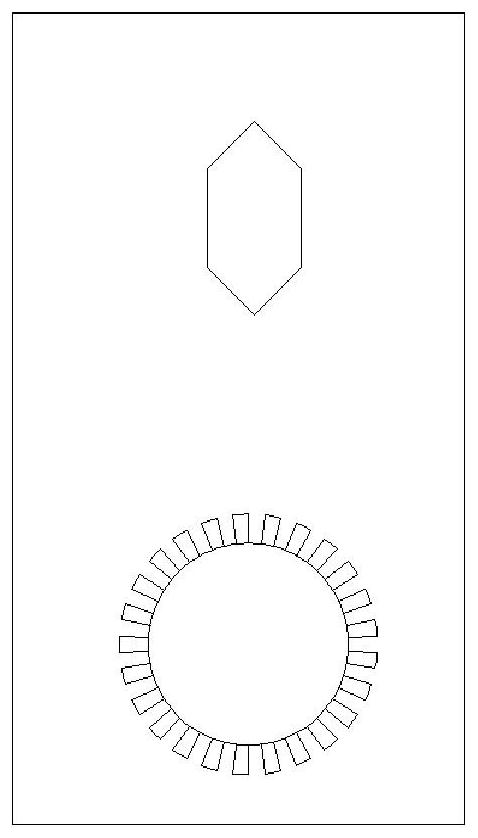

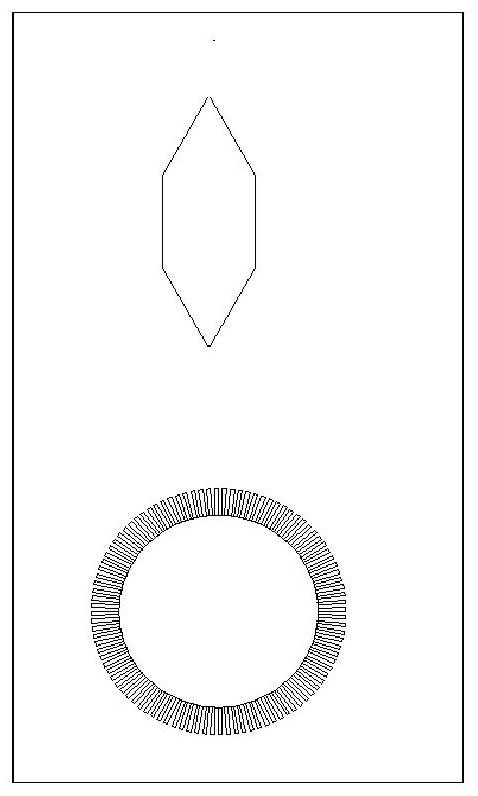

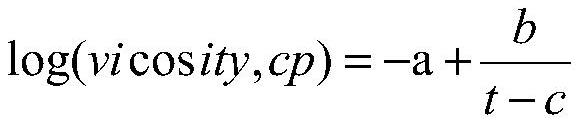

[0060] (3) When the temperature of the glass liquid drops to 1100°C-1300°C, the viscosity of the glass reaches 10 8 -10 10 When the viscosity is Poise, when the glass completes the solid-phase transformation, in order to cool down quickly, the glass plate needs to be relieved due to the large amount of stress inside. Preserv...

Embodiment 2

[0071] (1) Prepare glass substrate raw materials according to the following weight percentages, 58% by weight of silicon oxide, 11% by weight of boron oxide, 12% by weight of aluminum oxide, 2% by weight of barium oxide, 2.5% by weight of calcium oxide, 10% by weight Strontium oxide, 0.5% by weight zinc oxide, 2% by weight magnesium oxide, 0.5% by weight zirconia, 1% by weight clarifier CeO.

[0072] (2) The glass raw material is melted into glass liquid, clarified to remove impurities, and then formed into a solid glass plate, and then draws a line on the glass plate with a knife, and then breaks the glass plate at the line drawn.

[0073] (3) Molding viscosity of ultra-thin liquid crystal glass substrate at 900°C is 10 10 Poise.

[0074] (4) The annealing time of the ultra-thin liquid crystal glass substrate with a thickness of 0.3mm is 12s.

[0075] (5) The annealing temperature of the ultra-thin glass substrate with a thickness of 0.3mm is 800°C.

[0076] (6) Ultra-thin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com