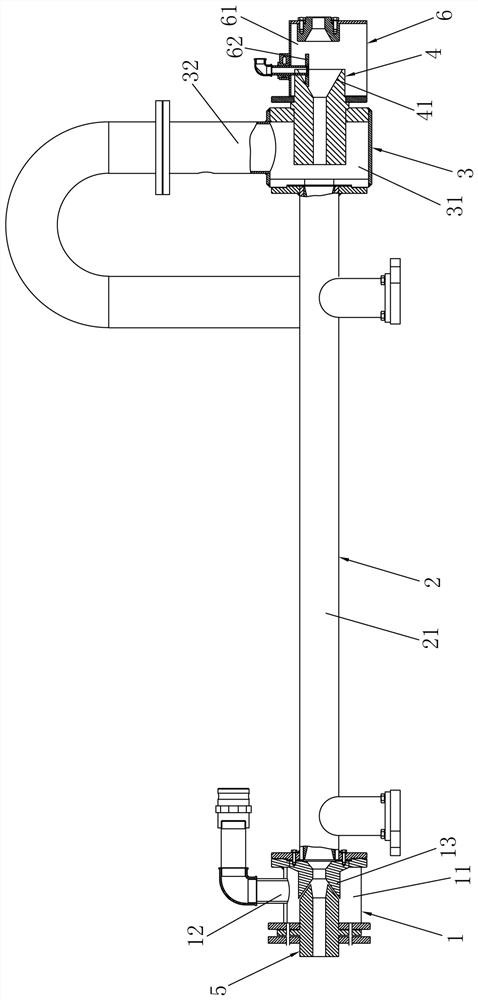

Rod and wire water-passing cooling device

A water-through cooling, rod and wire technology, applied in workpiece cooling devices, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of weakened cooling capacity of cooling devices, decreased cooling rate, reduced heat exchange capacity, etc., to achieve improved cooling Speed and cooling effect, reduction of production energy consumption, effect of rapid heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

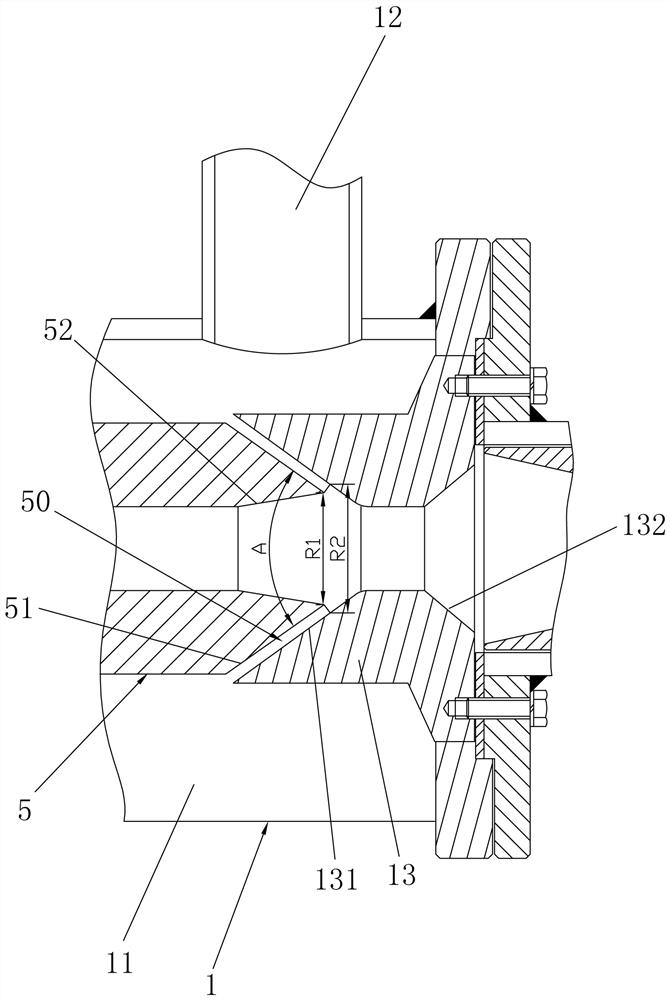

Method used

Image

Examples

Embodiment 1

[0032] The operating parameters of embodiment 1 and comparative example 1 are compared as follows:

[0033] Table 1 Comparison of operating parameters between Example 1 and Comparative Example 1

[0034]

[0035] The actual cooling energy consumption results of Example 1 and Comparative Example 1 are compared as follows:

[0036] Table 2 Comparison of actual cooling energy consumption between Example 1 and Comparative Example 1

[0037]

[0038] It can be seen from Table 2 that under the same cooling effect, the total pipe flow rate and power consumption per ton of steel in Example 1 are far less than those in Comparative Example 1, indicating that the rod and wire water-through cooling device adopted in Example 1 has higher cooling efficiency and more Strong cooling capacity, able to cool the rolled piece evenly and rapidly in a short time.

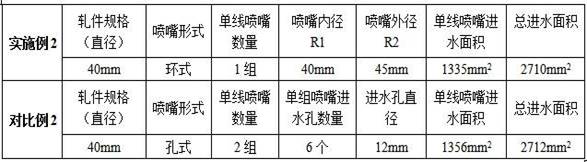

[0039] 2. Taking the controlled cooling process of rebar with a specification of Φ40mm as an example, the starting rolling temp...

Embodiment 2

[0042] The operating parameters of embodiment 2 and comparative example 2 are compared as follows:

[0043] Table 3 Comparison Table of Operating Parameters of Embodiment 2 and Comparative Example 2

[0044]

[0045] The actual cooling energy consumption results of embodiment 2 and comparative example 2 are compared as follows:

[0046] Table 4 Comparison of actual cooling energy consumption between Example 2 and Comparative Example 2

[0047]

[0048] It can be seen from Table 4 that under the same cooling effect, the total pipe flow rate and power consumption per ton of steel in Example 2 are much smaller than those in Comparative Example 2, indicating that the water-through cooling device adopted in Example 2 has higher cooling efficiency and stronger cooling efficiency. Cooling capacity, able to cool the rolled piece evenly and rapidly in a short period of time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com