Emulsion-type acrylate pressure-sensitive adhesive, preparation method thereof and double-sided adhesive tape

An acrylate and pressure-sensitive adhesive technology, applied in the field of pressure-sensitive adhesives, can solve the problems of low peeling force and initial adhesion, poor temperature resistance, etc., achieve high peeling force, improve poor temperature resistance, and simplify the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

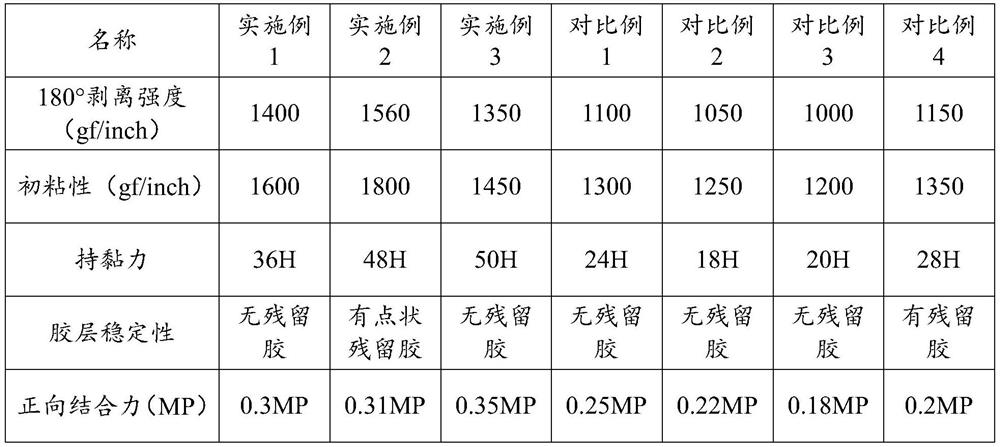

Examples

Embodiment 1

[0031] 1) Under rapid stirring, put 25 parts of deionized water into the emulsification tank, then add 0.15 parts of emulsifier, 71 parts of butyl acrylate, 1 part of methyl acrylate, 1.7 parts of (meth)acrylic acid, 1.1 parts of hydroxyethyl acrylate Esters, 0.05 parts of tert-dodecyl mercaptan, the stirring speed is 400r / min, stirring for 20min, the monomer pre-emulsion is prepared.

[0032] 2) Completely dissolve emulsifier A501 of 0.05wt% of the total amount of monomers in deionized water at 35°C and add to the reactor, add 0.5wt% of ammonium persulfate of the total amount of monomers, and then add equivalent Add 40wt% deionized water to the monomer pre-emulsion and 0.05wt% ammonium bicarbonate in the total amount of the monomer, continue to heat up to 80°C-90°C, add 2wt% monomer pre-emulsion to the reaction kettle, and control the temperature at 75- React at 90°C for 10-20 minutes, the reflux gradually disappears, and the emulsion in the reactor appears milky blue, indica...

Embodiment 2

[0037] 1) Under rapid stirring, put 22.47 parts of deionized water, 0.2 parts of emulsifier OT-75, 60 parts of butyl acrylate, 14 parts of ethyl acrylate, 1 part of hydroxyethyl acrylate, 0.1 part of methyl acrylate into the emulsification tank , 2 parts of (meth)acrylic acid, 0.03 part of tert-dodecyl mercaptan, stirred at 400r / min for 20min, and the monomer pre-emulsion was prepared.

[0038]2) Dissolve the emulsifier OP-10 with 0.05wt% of the total amount of monomers in deionized water at about 35°C and add it into the reactor, then add ammonium persulfate of 0.3wt% of the total amount of monomers into the reactor Add monomer pre-emulsion 40wt% deionized water and monomer total amount of 0.05wt% ammonium bicarbonate, continue to heat up to 80°C-90°C, add 2wt% monomer pre-emulsion to the reaction kettle, temperature control 80 React at -90°C for 10-20 minutes, the reflux gradually disappears, and the emulsion in the reactor appears milky blue, indicating that the synthesis o...

Embodiment 3

[0043] 1) Under rapid stirring, put 30 parts of deionized water, 0.1 parts of emulsifier H95, 35.85 parts of butyl acrylate, 29 parts of ethyl acrylate, 1.5 parts of hydroxyethyl acrylate, 1 part of methyl methacrylate into the emulsification tank , 2 parts of (meth)acrylic acid, 0.05 part of tert-dodecyl mercaptan, stirred at 400r / min for 20min, and the monomer pre-emulsion was prepared.

[0044] 2) Dissolve 0.05wt% emulsifier OP-10 of the total amount of monomers completely with deionized water at about 35°C and add it to the reaction kettle, add ammonium persulfate of 0.4wt% of the total amount of monomers, and pour into the reaction kettle Add 40wt% deionized water of the monomer pre-emulsion and 0.05wt% ammonium bicarbonate of the total amount of monomers, continue to heat up to 80-90°C, add 2wt% monomer pre-emulsion to the reaction kettle, and control the temperature at 80-90 ℃, react for 10-20 minutes, the reflux gradually disappears, and the emulsion in the reactor app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com