Thermopile infrared sensor with linear thermal resistance correction and preparation method thereof

A thermopile sensor, thermal resistance technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical radiation detectors, etc. Increase the workload of packaging and other issues to achieve the effect of improving sensitivity, improving overall accuracy, and increasing light reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

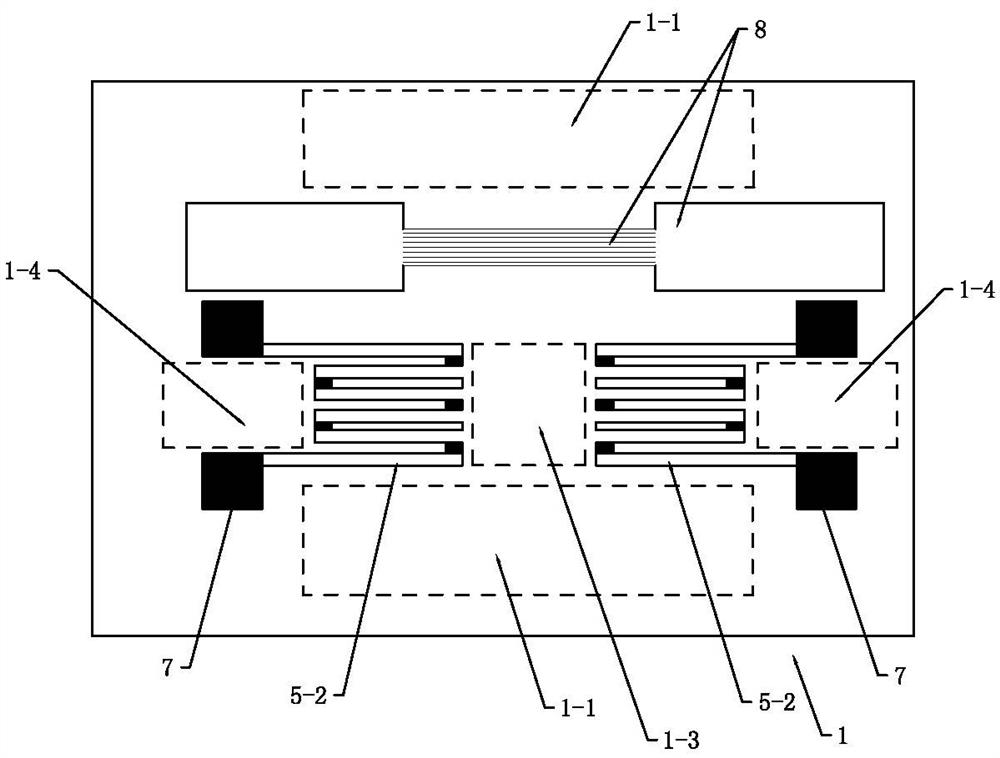

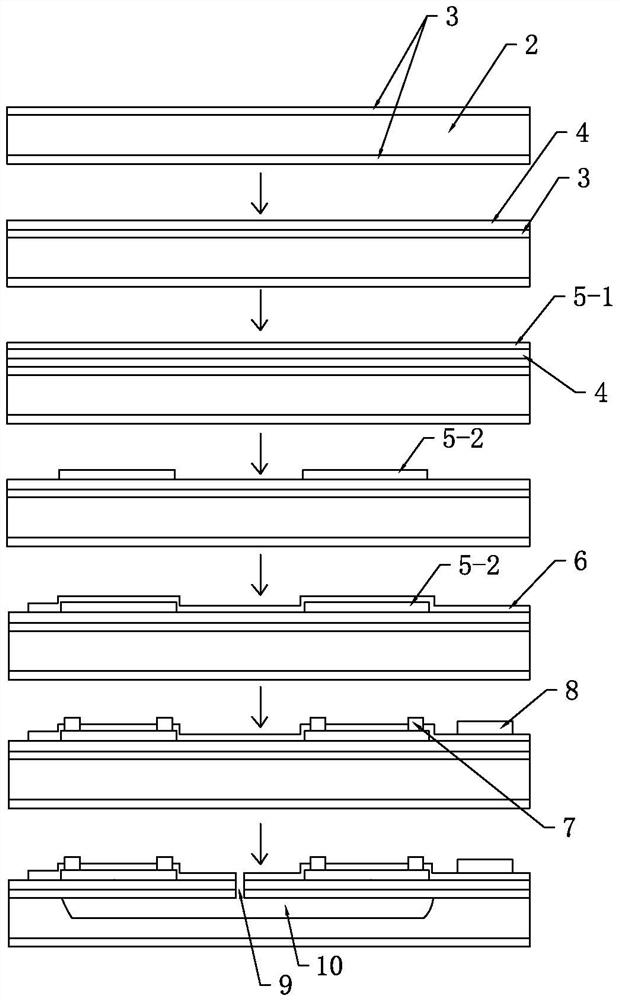

Embodiment 1

[0036] The thermopile sensor with linear thermal resistance correction of this embodiment includes a silicon substrate, SiO 2 Thin films, silicon nitride layers, polysilicon strips, SiO 2 Insulation layer, metal electrodes and linear metal RTD with SiO on silicon substrate in sequence 2 The thin film and the silicon nitride layer form a supporting film; the polysilicon strips are arranged on the upper surface of the silicon nitride layer, and the polysilicon strips are doped with B ions. SiO 2 The insulating layer covers the polysilicon strip, and the metal electrode penetrates the SiO above the polysilicon strip 2 The insulating layer is in contact with the polysilicon strip, the metal electrode and the polysilicon strip form a thermocouple, and a plurality of thermocouples form a thermopile, and the linear metal thermal resistance is set on the SiO 2 On the insulating layer and the silicon substrate, and the linear metal thermal resistance is located beside the thermopile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com