Halogen-free phosphorus-containing low-dielectric copper-clad plate and preparation method thereof

A copper-clad laminate and low-dielectric technology, which is applied in the field of electronic materials and its preparation, can solve problems such as polluting the environment and endangering human health, achieve low corrosion resistance, improve the overall safety factor, and improve heat resistance and flame resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

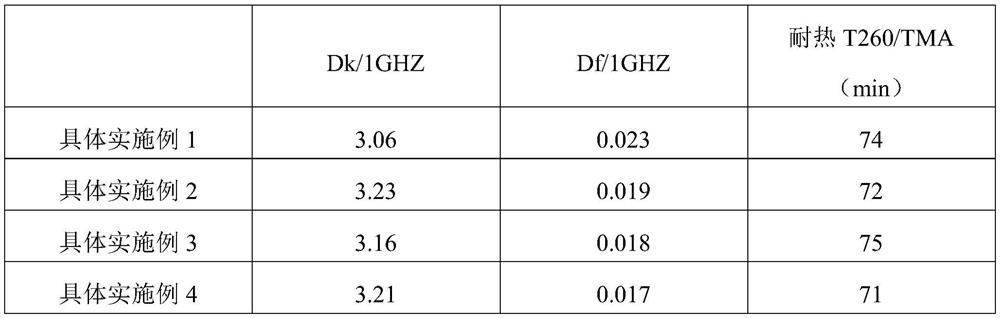

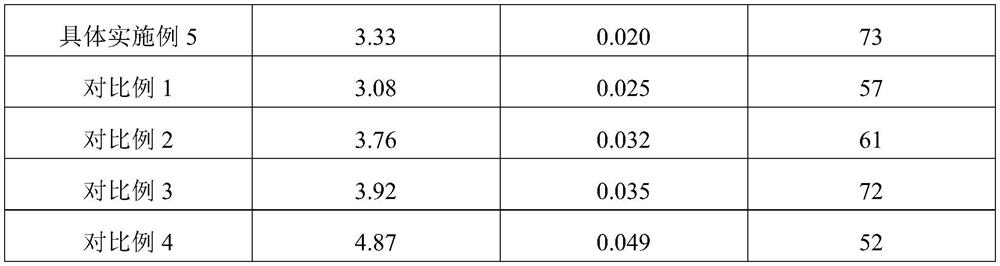

Examples

Embodiment

[0031] Embodiment: A halogen-free phosphorus-containing low-dielectric copper-clad laminate includes two layers of copper foil layers and an insulating dielectric layer located between the two layers of copper foil layers, wherein the insulating dielectric layer is composed of at least one prepreg; Each prepreg is obtained by immersing glass fiber cloth in resin glue and then drying; the resin glue includes the following components in parts by weight: 140-170 parts of phosphorus-containing epoxy resin, 14- 17 parts of cyanate ester resin, 3-6 parts of curing agent, 0.03-0.07 parts of curing agent accelerator, 40-80 parts of solvent, 27-30 parts of o-cresol type epoxy resin and 40-70 parts of inorganic filler.

[0032] Specifically, the phosphorus-containing epoxy resin is a DOPO-type modified phosphorus-containing epoxy resin with a phosphorus mass fraction of 2wt.%-4wt.%. The resin is a modified phosphorus-based epoxy resin with multiple modified functional groups. The copper...

specific Embodiment 1

[0040] A halogen-free phosphorus-containing low-dielectric copper clad laminate, comprising two layers of copper foil and an insulating dielectric layer between the two layers of copper foil, wherein the insulating dielectric layer is composed of 6 prepregs; each prepreg It is obtained by impregnating glass fiber cloth in resin glue solution and then drying. Its preparation process is as follows:

[0041] S1, preparation of resin glue: take by weight, 140 parts of phosphorus-containing epoxy resin, 17 parts of cyanate resin, 4 parts of curing agent, 0.04 part of curing agent accelerator, 50 parts of solvent, 27 parts of o-cresol Add type epoxy resin and 50 parts of inorganic filler into the mixer, stir at 30°C for 4 hours to obtain resin glue;

[0042] S2, preparation of glass fiber cloth impregnated material: apply the resin glue prepared in step S1 on both sides of the glass fiber cloth by dipping, and dry at 200°C for 3 minutes to prepare the glass fiber cloth Dip sheet; ...

specific Embodiment 2

[0050] A halogen-free phosphorus-containing low-dielectric copper clad laminate, comprising two layers of copper foil and an insulating dielectric layer between the two layers of copper foil, wherein the insulating dielectric layer is composed of 6 prepregs; each prepreg It is obtained by impregnating glass fiber cloth in resin glue solution and then drying. Its preparation process is as follows:

[0051] S1, preparation of resin glue: take by weight, 150 parts of phosphorus-containing epoxy resin, 15 parts of cyanate resin, 5 parts of curing agent, 0.05 part of curing agent accelerator, 60 parts of solvent, 28 parts of o-cresol Type epoxy resin and 40 parts of inorganic fillers were added to the mixer, and stirred at 32°C for 4.2 hours to obtain resin glue;

[0052] S2, preparation of glass fiber cloth impregnated material: apply the resin glue prepared in step S1 on both sides of the glass fiber cloth by dipping, and dry at 200°C for 2 minutes to prepare the glass fiber cloth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com