A kind of flotation composite collector and its preparation method and application

A composite collector and flotation technology, used in flotation, oxygen-containing functional group reduction preparation, organic chemistry, etc., can solve the problems of complex treatment, long time, low yield, etc. The effect of reducing production cost and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 9.91 parts of tert-butyl peroxybenzoate (98.0% content) into a reactor containing 15.55 parts of toluene, add 2.89 parts of sodium bisulfite, and react for 20 minutes, then add 3.60 parts of hydroxylamine hydrochloride (98.5% content) and 4.38 parts of sodium hydroxide (content: 96.0%), stirred and reacted for 3 hours, filtered to remove the inorganic salt obtained by the reaction, and recovered the toluene solvent by distillation to obtain a white composite collector product.

Embodiment 2

[0042] Add 9.91 parts of tert-butyl peroxybenzoate (98.0% content) into a reactor containing 20.00 parts tetrahydrofuran, add 3.57 parts sodium sulfite, and react for 20 minutes, then add 3.60 parts hydroxylamine hydrochloride (98.5% content) and 6.93 parts Potassium hydroxide (85.0%) was stirred and reacted for 3 hours, the inorganic salt obtained by the reaction was removed by filtration, and the toluene solvent was recovered by distillation to obtain a pale yellow composite collector product.

Embodiment 3

[0044]9.91 parts of tert-butyl peroxybenzoate (content is 98.0%) are added in the reactor that 10.00 parts of toluene+5.00 parts of ethanol are housed, add 4.40 parts of sodium thiosulfate, after reacting for 20min, add 8.45 parts of hydroxylamine sulfate (content 99%) and 4.38 parts of sodium hydroxide (content is 96.0%), stirred for 3h, filtered to remove the inorganic salt obtained by the reaction, distilled and recovered toluene and ethanol solvent to obtain a pale yellow composite collector product.

[0045] The compound collector product obtained is weighed, and calculates its theoretical output according to the addition of raw material, calculates yield, and wherein the yield of hydroxamic acid compounds prepared in embodiment 1-3 is respectively 91.5%, 89.29%, 88.21% %.

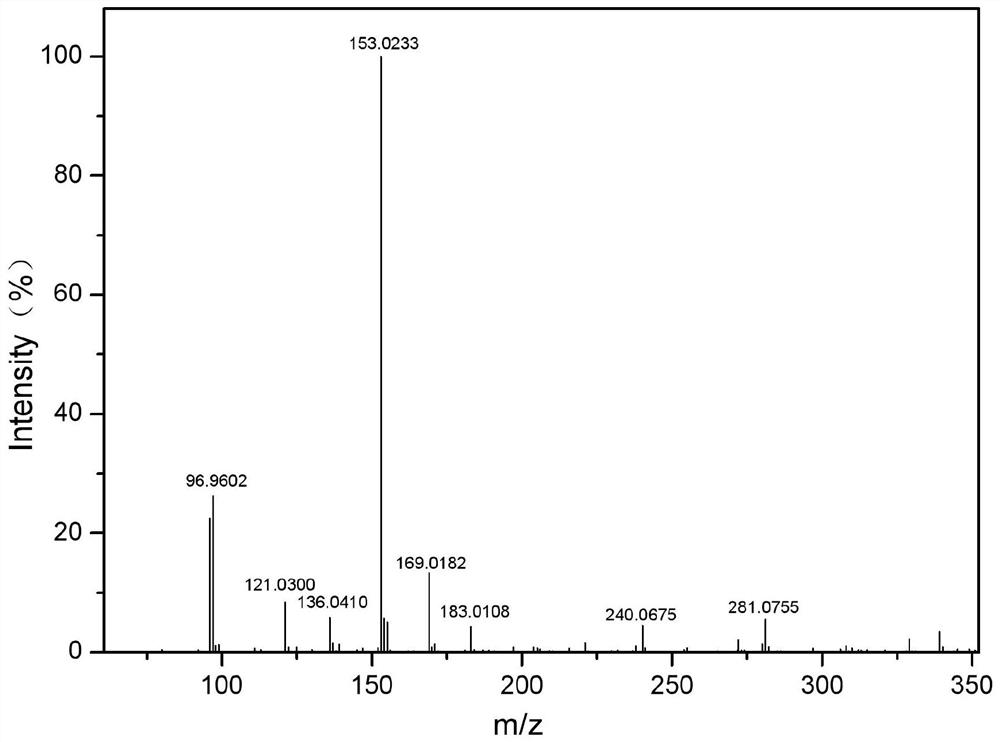

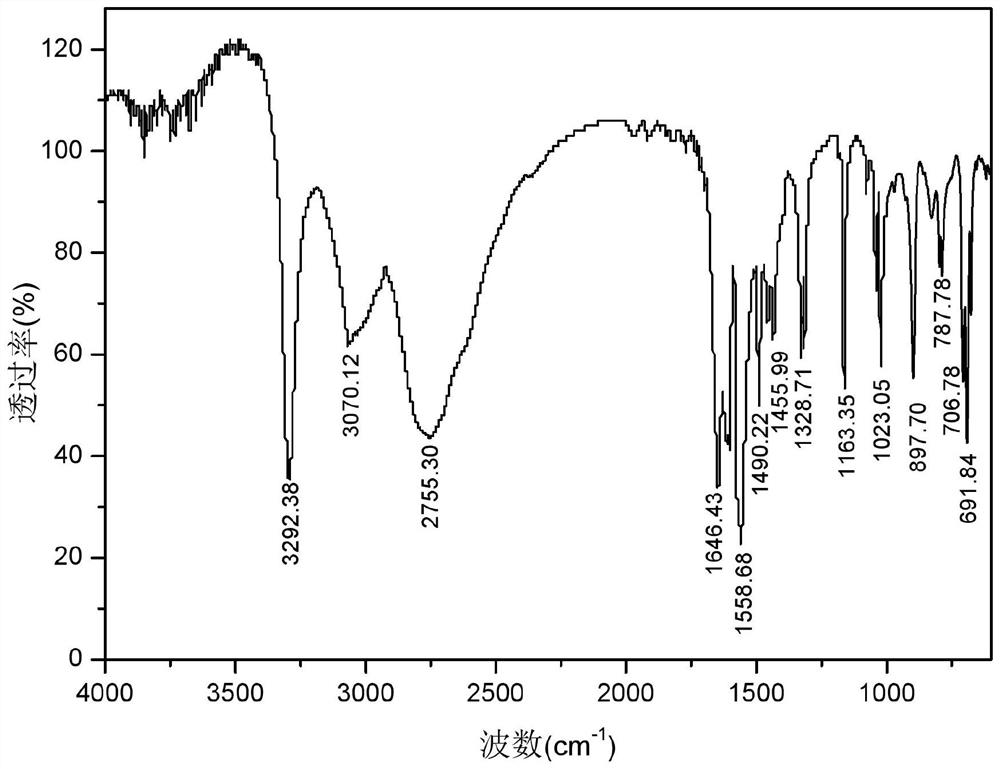

[0046] Structure Characterization

[0047] The structure of the flotation composite collector was characterized by mass spectrometry, and the pure hydroxamic acid compounds were obtained after separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com